Welding flux for submerged-arc welding of 12Cr2Mo1R alloy steel pipe and preparation method of welding flux

A 12cr2mo1r, alloy steel pipe technology, used in arc welding equipment, welding equipment, welding equipment, etc., can solve the problems of poor wettability and poor slag removal, and achieve the effect of good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

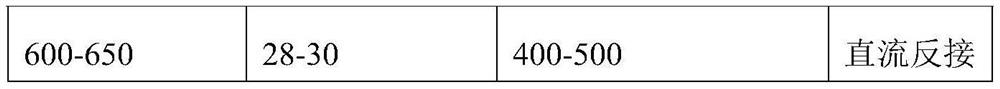

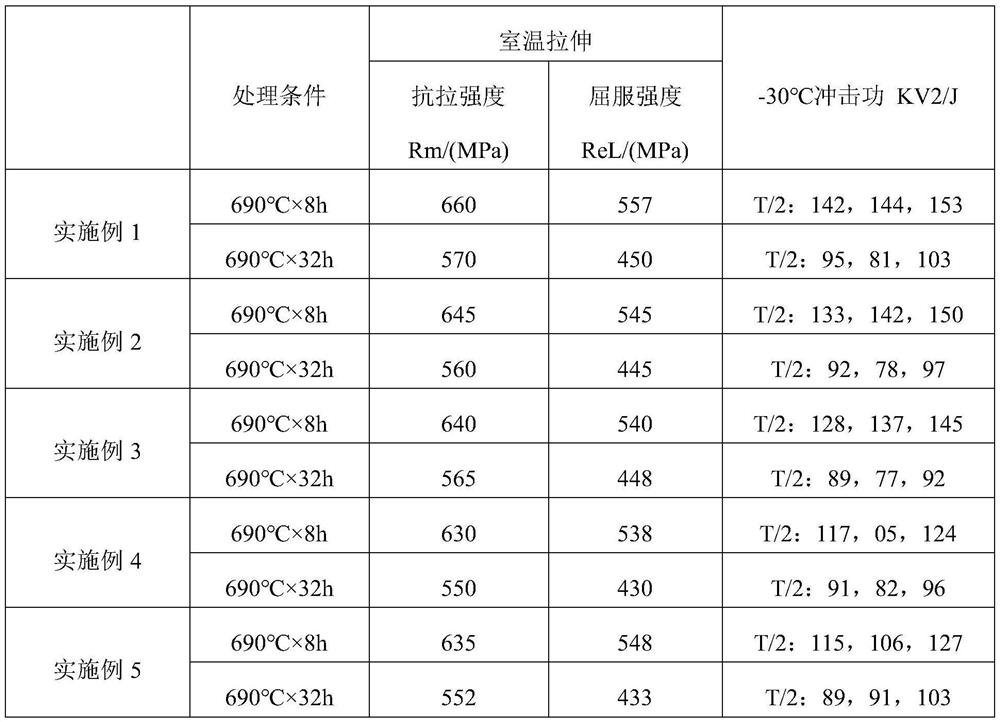

Embodiment 1

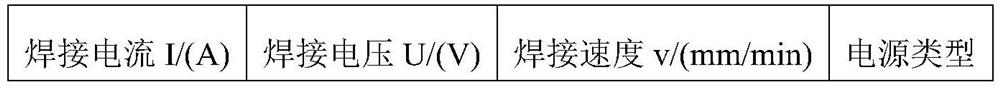

[0033] A flux for submerged arc welding of 12Cr2Mo1R alloy steel pipes, prepared from the following raw materials in parts by weight: 17 parts by weight of aluminum oxide, 13 parts of calcium oxide, 7 parts of manganese oxide, 22 parts of magnesium fluoride, 20 parts of magnesium oxide, 8 parts of silicon, 5 parts of ferrosilicon, 6 parts of electrolytic manganese, 1.5 parts of medium carbon ferrochromium, 6 parts of chromium powder, 3 parts of molybdenum powder, 4 parts of rare earth fluoride.

[0034]The preparation method of the flux is as follows: mix the raw materials used for preparing welding evenly, add water glass and stir and mix evenly to make a granular mixture with a particle size of 40 meshes; The material is sintered at 350°C for 30 minutes, and then heated to 850°C for 2 hours to obtain the flux;

[0035] Described water glass is pure potassium water glass, and its modulus is equal to 2.8, and the Baume degree at 20 ℃ is 45 ° Be '.

Embodiment 2

[0037] The flux in this embodiment is basically the same as that in Example 1. The difference is that the flux in this embodiment is prepared from the following raw materials in parts by weight: 16 parts of aluminum oxide, 12 parts of calcium oxide, 5 parts of manganese oxide, fluoride 16 parts of magnesium, 17 parts of magnesium oxide, 5 parts of silicon oxide, 3 parts of ferrosilicon, 4 parts of electrolytic manganese, 1 part of medium carbon ferrochrome, 4 parts of chromium powder, 2 parts of molybdenum powder, and 2 parts of rare earth fluoride.

Embodiment 3

[0039] The flux in this embodiment is basically the same as that in Example 1. The difference is that the flux in this embodiment is prepared from the following raw materials in parts by weight: 19 parts of aluminum oxide, 14 parts of calcium oxide, 8 parts of manganese oxide, fluoride 25 parts of magnesium, 22 parts of magnesium oxide, 10 parts of silicon oxide, 7 parts of ferrosilicon, 7 parts of electrolytic manganese, 2.5 parts of medium carbon ferrochrome, 8 parts of chromium powder, 4 parts of molybdenum powder, and 5 parts of rare earth fluoride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com