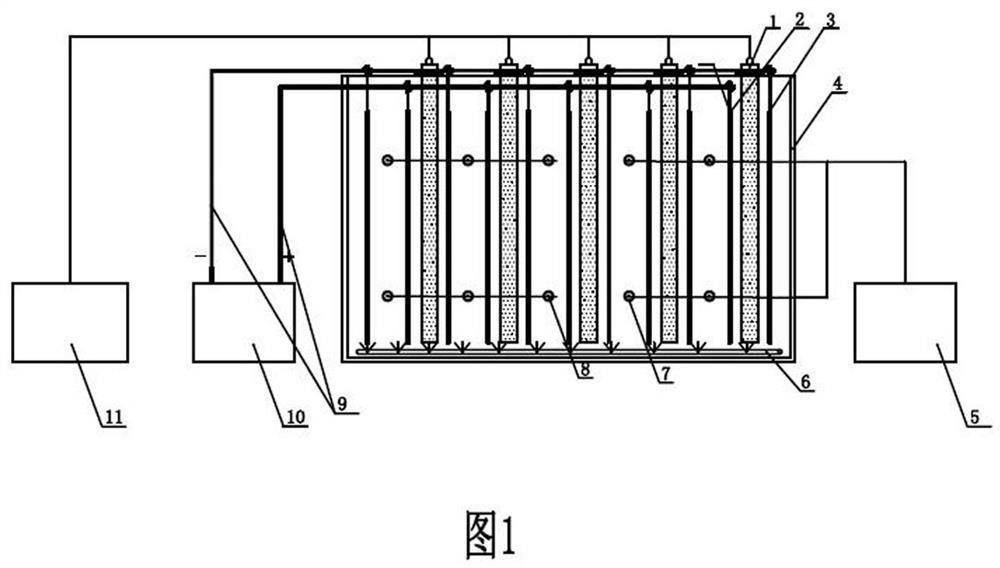

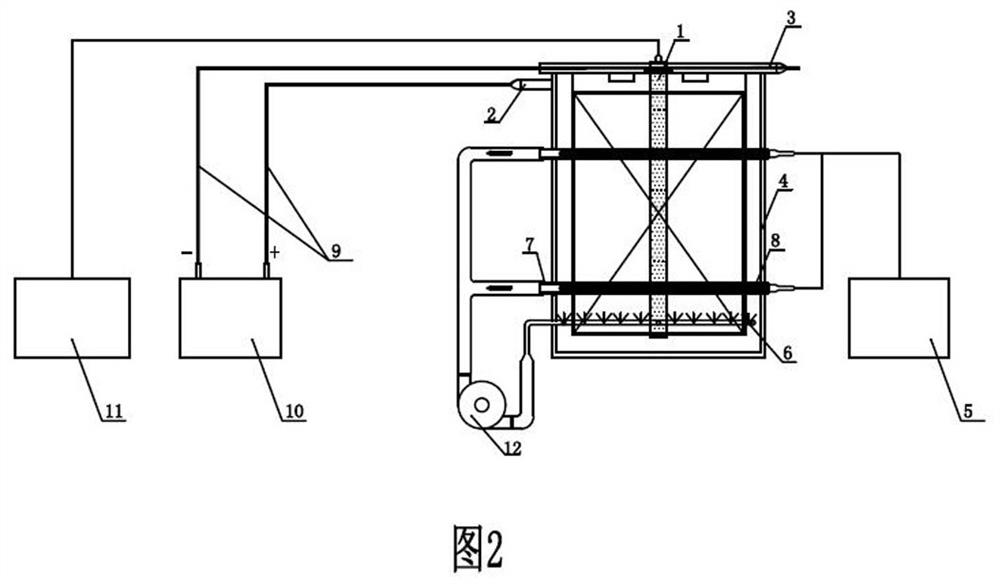

Composite catalytic oxidation treatment system for high-salinity wastewater

A catalytic oxidation and treatment system technology, which is applied in the field of high-salt wastewater composite catalytic oxidation treatment system, can solve the problems of loss of transmission effect and limited wastewater treatment effect, and achieve the effects of reduced treatment cost, improved oxidation efficiency, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Adopt the treatment system provided by the present invention to process the production wastewater of a certain rubber additive factory:

[0058] Among them, the electrolytic anode plate 2 adopts a titanium-based electrode, and the surface catalytic component is SnO 2 ,Sb 2 o 3 ,IrO 2 ,RuO 2 , Ta 2 o 5 The mixture, the mass ratio is 2:2:2:1:1, the distance between the plates is 5 cm, and the current density is 2.5mA / cm 2 , the wavelength of ultraviolet light emitted by the ultraviolet lamp is 185-254nm, the ultrasonic frequency is 200KHZ; the ultrasonic sound intensity adjustment range is 10W / cm 2 ; The hydraulic retention time of the waste water is 120 minutes, and the flow rate of the induced draft fan 12 is 50L / min. The total power of the equipment is 18Kw.

[0059] Influent COD is 8650mg / L, NH 3 -N is 1200mg / L, conductivity is 116000s / cm;

[0060] Effluent COD is 128mg / L, NH 3 -N is 5.2mg / L, and the power consumption per ton of water is 36Kw.h.

Embodiment 2

[0062] Adopt the processing system provided by the invention to process the evaporated mother liquor of a certain chemical plant:

[0063] Among them, the electrolytic anode plate 2 adopts a titanium-based electrode, and the surface catalytic component is SnO 2 ,Sb 2 o 3 ,IrO 2 ,RuO 2 , Ta 2 o 5 The mixture, the mass ratio is 2:2:1:2:2, the distance between the plates is 5 cm, and the current density is 5mA / cm 2 , the wavelength of ultraviolet light emitted by the ultraviolet lamp is 185-254nm, the ultrasonic frequency is 100KHZ; the ultrasonic sound intensity adjustment range is 20W / cm 2 The hydraulic retention time of the waste water is 60 minutes, and the flow rate of the induced draft fan 12 is 100L / min. The total power of the equipment is 30Kw.

[0064] Influent COD is 6500mg / L, NH 3 -N is 98mg / L, and the conductivity is 56000s / cm;

[0065] Effluent COD is 212mg / L, NH 3 -N is 0.5mg / L, and the power consumption per ton of water is 30Kw.h.

Embodiment 3

[0067] Adopt the treatment system provided by the invention to process the waste water produced by a certain dye intermediate:

[0068] Among them, the electrolytic anode plate 2 adopts a titanium-based electrode, and the surface catalytic component is SnO2 ,Sb 2 o 3 ,IrO 2 ,RuO 2 , Ta 2 o 5 The mixture, the mass ratio is 1:1:2:1:1, the distance between the plates is 10 cm, and the current density is 2mA / cm 2 , the wavelength of ultraviolet light emitted by the ultraviolet lamp is 185-254nm, the ultrasonic frequency is 100KHZ; the ultrasonic sound intensity adjustment range is 5W / cm 2 ; The hydraulic retention time of the waste water is 30 minutes, and the flow rate of the induced draft fan 12 is 30L / min. The total power of the equipment is 10Kw.

[0069] Influent COD is 3650mg / L, NH 3 -N is 420mg / L, and the conductivity is 56000s / cm;

[0070] Effluent COD is 31mg / L, NH 3 -N is 3.8mg / L and the power consumption per ton of water is 5Kw.h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com