Water-soluble lead-free flux paste, washing solder paste and preparation method of washing solder paste

A solder paste and water-soluble technology, which is applied in the field of water-washed ultra-fine tin powder water-soluble lead-free high-temperature solder paste and its preparation, can solve the problem of inability to meet more precise operation requirements, strong aggressiveness of solder paste to tin powder, Affect the reliability of the welding effect and other issues, to achieve the effect of low voids, good cleanability, and detailed steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

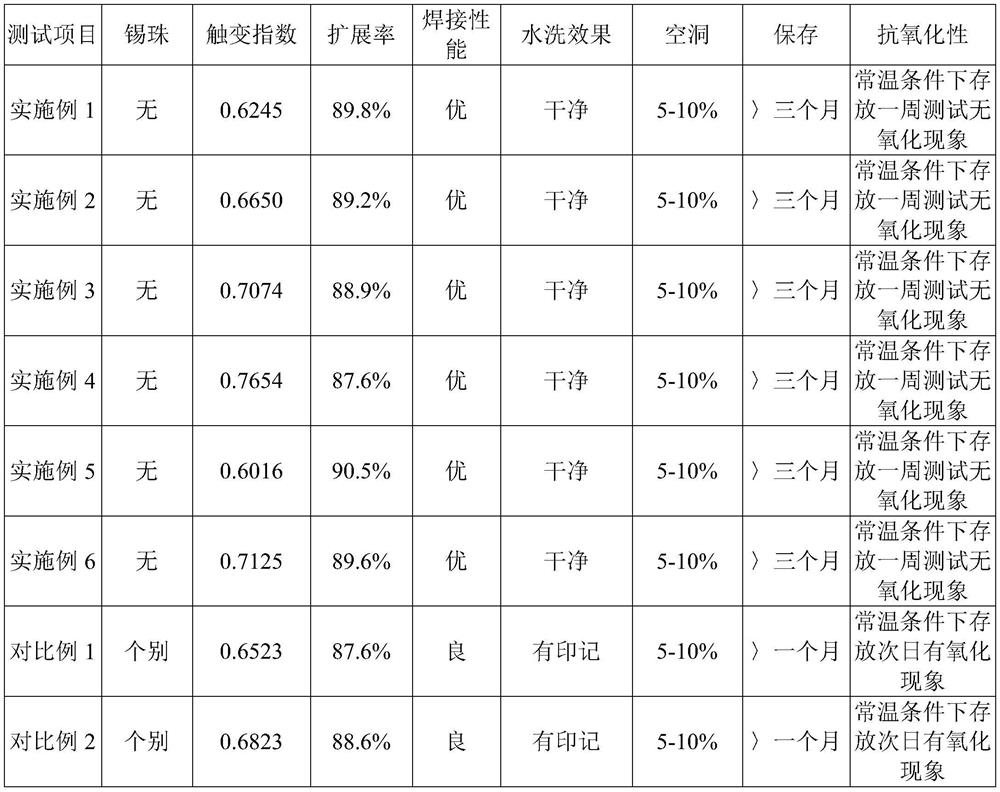

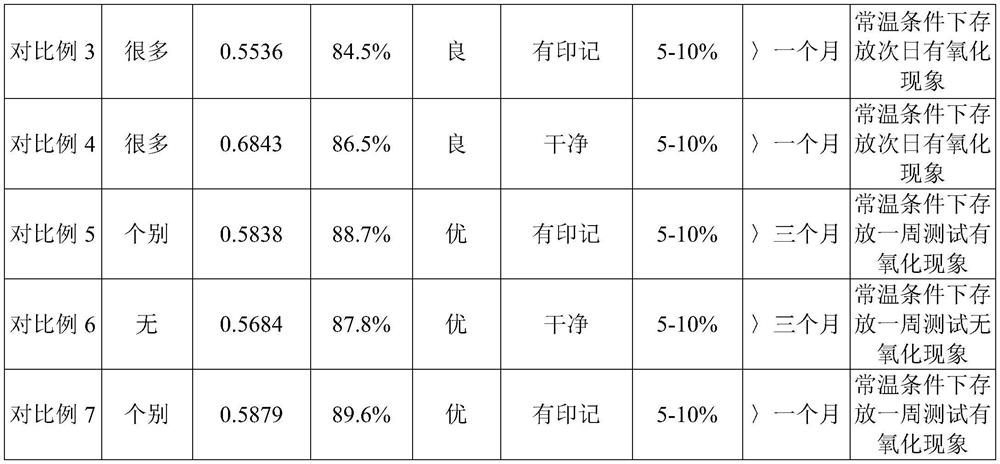

Examples

Embodiment 1

[0054] The water-soluble lead-free soldering paste consists of the following components in parts by weight:

[0055] 51 parts of antioxidant, 16.8 parts of organic solvent, 4 parts of thixotropic agent, 12 parts of active agent, 8.2 parts of corrosion inhibitor, and 8 parts of surfactant.

[0056] Among them, the antioxidant is composed of water-soluble polymerized rosin, high acid value liquid organic acid EB9, tetrahydroxypropyl ethylenediamine, and polyoxyethylene tallow amine in a weight ratio of 2:4.8:2.4:1; the organic solvent is composed of Tetraethylene glycol dimethyl ether and 1-decyl alcohol are mixed at a weight ratio of 1:2; the thixotropic agent is a water-soluble polyamide, and the active agent is malonic acid, dimethylolpropionic acid, succinic acid and cyclic Hexylamine adipate is composed by weight ratio of 1:12:5:6; the corrosion inhibitor is composed of diethylimidazole and triethanolamine by weight ratio of 1.56:1.

[0057] Wherein the water-soluble polya...

Embodiment 2

[0068] The water-soluble lead-free soldering paste consists of the following components in parts by weight:

[0069] 51 parts of antioxidant, 16.8 parts of organic solvent, 6 parts of thixotropic agent, 12 parts of active agent, 8.2 parts of corrosion inhibitor and 8 parts of surfactant.

[0070] Among them, the antioxidant is composed of water-soluble polymerized rosin, high acid value liquid organic acid EB9, tetrahydroxypropyl ethylenediamine, and polyoxyethylene tallow amine in a weight ratio of 3:5:3:1; the organic solvent is composed of Tetraethylene glycol dimethyl ether and 1-decyl alcohol are mixed in a weight ratio of 1:3; the thixotropic agent is composed of water-soluble polyamide and water-based vinyl ether in a weight ratio of 4:2, and the active agent is made of propanediol Acid, dihydroxymethylpropionic acid, succinic acid and cyclohexylamine adipate in a weight ratio of 1:15:7:8; the corrosion inhibitor consists of diethylimidazole and triethanolamine in a wei...

Embodiment 3

[0083] The water-soluble lead-free soldering paste consists of the following components in parts by weight:

[0084] 51 parts of antioxidant, 16.8 parts of organic solvent, 8 parts of thixotropic agent, 12 parts of active agent, 8.2 parts of corrosion inhibitor and 8 parts of surfactant.

[0085] Among them, the antioxidant is composed of water-soluble polymerized rosin, high acid value liquid organic acid EB9, tetrahydroxypropyl ethylenediamine, and polyoxyethylene tallow amine in a weight ratio of 1:3:2:1; the organic solvent is composed of Tetraethylene glycol dimethyl ether and 1-decyl alcohol are mixed in a weight ratio of 1:1; the thixotropic agent is composed of water-soluble polyamide and water-based vinyl ether in a weight ratio of 6:2, and the active agent is made of propanediol Acid, dihydroxymethylpropionic acid, succinic acid and cyclohexylamine adipate in a weight ratio of 1:10:3:4; the corrosion inhibitor is composed of diethylimidazole and triethanolamine in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com