Glass powder, preparation method thereof and application of glass powder in TOPCon battery

A glass frit and battery technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as poor EL, increased sintering furnace temperature, and low electrical performance, so as to reduce current loss, optimize manufacturing process, and improve conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

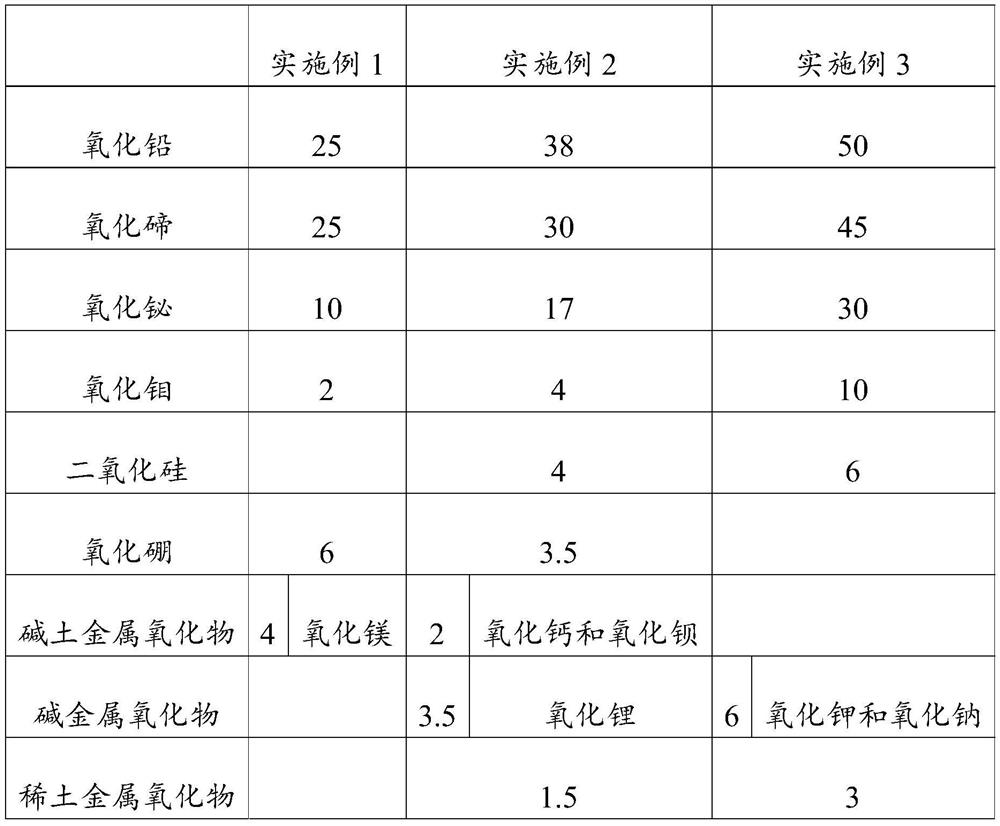

Examples

Embodiment 1

[0037] After selecting the components and parts by weight according to Example 1 described in Table 1, the preparation method of the glass powder comprises the following steps:

[0038] (1) Weigh lead oxide, tellurium oxide, bismuth oxide, molybdenum oxide, silicon dioxide, boron oxide, alkaline earth metal oxides, alkali metal oxides and rare earth metal oxides and disperse them evenly, and smelt them in a high-temperature furnace. The melting temperature is 900°C, and the melting time is 60 minutes. After taking it out, it is quenched and cooled with pure water to obtain A;

[0039] (2) The A obtained in the step (1) is subjected to ball milling, the time of ball milling is 6h, and the sieve passed after the ball milling is 300 mesh sieves, left standing after sieving, drying and pulverizing after removing the supernatant, Obtain the glass powder.

Embodiment 2

[0041] After carrying out component and parts by weight according to the embodiment 2 described in table 1 selection, the preparation method of described glass powder comprises the following steps:

[0042](1) Weigh lead oxide, tellurium oxide, bismuth oxide, molybdenum oxide, silicon dioxide, boron oxide, alkaline earth metal oxides, alkali metal oxides and rare earth metal oxides and disperse them evenly, and smelt them in a high-temperature furnace. The melting temperature is 1050°C, and the melting time is 90 minutes. After taking it out, it is quenched and cooled with pure water to obtain A;

[0043] (2) The A obtained in the step (1) is subjected to ball milling, the time of ball milling is 15h, and the sieve passed after the ball milling is 300 mesh sieves, left standing after sieving, drying and pulverizing after removing the supernatant, Obtain the glass powder.

Embodiment 3

[0045] After carrying out component and parts by weight according to embodiment 3 described in table 1 selection, the preparation method of described glass powder comprises the following steps:

[0046] (1) Weigh lead oxide, tellurium oxide, bismuth oxide, molybdenum oxide, silicon dioxide, boron oxide, alkaline earth metal oxides, alkali metal oxides and rare earth metal oxides and disperse them evenly, and smelt them in a high-temperature furnace. The melting temperature is 1100°C, and the melting time is 120 minutes. After taking it out, it is quenched and cooled with pure water to obtain A;

[0047] (2) The A obtained in the step (1) is subjected to ball milling, the time of ball milling is 18h, and the sieve passed after the ball milling is 300 mesh sieves, left standing after sieving, drying and pulverizing after removing the supernatant, Obtain the glass powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com