Semiconductor cleaning agent and preparation method thereof

A cleaning agent and semiconductor technology, which is applied in the preparation of detergent mixture compositions, detergent compositions, detergent compounding agents, etc., can solve the problem of unsatisfactory removal effect of strong lye cleaning agents, eutrophication of water sources, and poor environment. friendly and other problems, to achieve the effect of rapid peeling and emulsification of oil stains, meeting production needs, and excellent dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

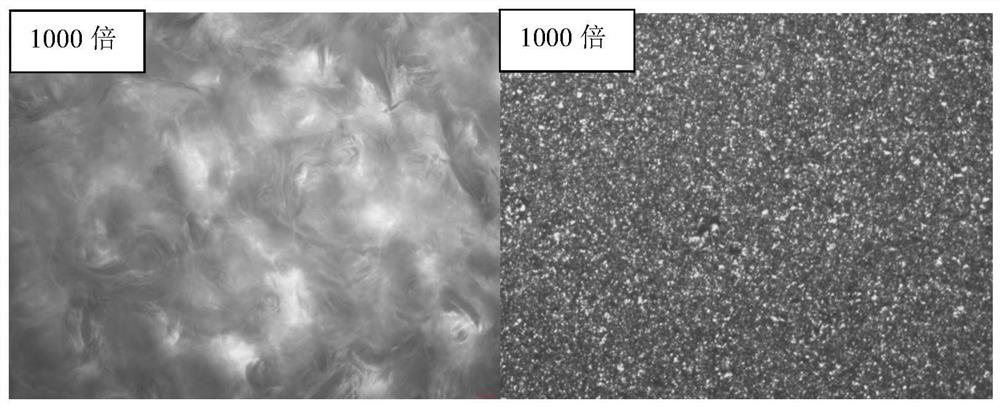

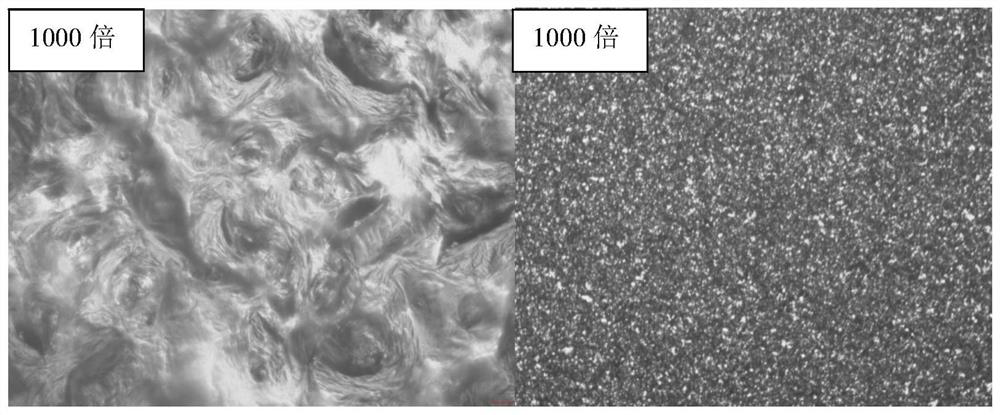

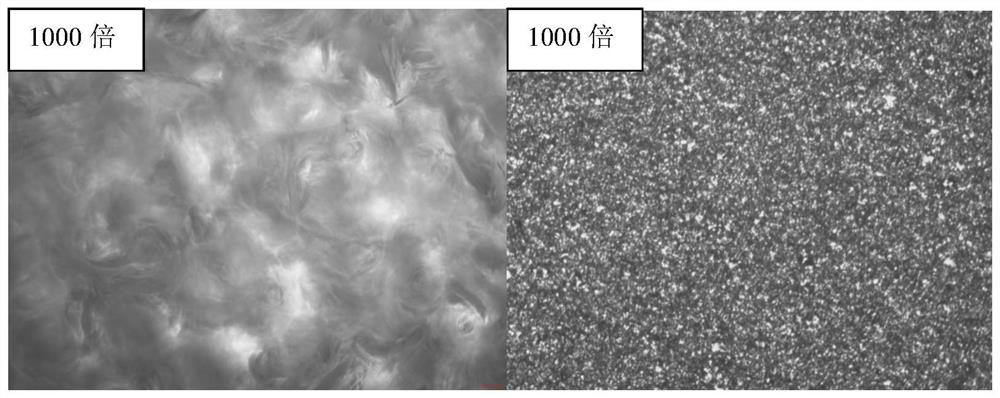

Image

Examples

Embodiment 1

[0037] S1. Configure the first mixed solution:

[0038] Its ingredients and dosage are as follows:

[0039] Organic solvents:

[0040] Diethylene glycol butyl ether 1.5g

[0041] 2-Methyl-2,4-pentanediol 2.5g

[0042] Nonionic Surfactants:

[0043] DOW EH-9 Isomerized Alcohol Polyoxyethylene Ether 2.5g

[0044] Octylphenol polyoxyethylene polyoxypropylene ether 0.5g

[0045] Anionic surfactants:

[0046] Ethanolamine dodecylbenzenesulfonate 4.5g

[0047] Sodium dihexyl succinate monosulfonate 2g

[0048] Sodium xylene sulfonate 3g

[0049] Preparation process: Add 100 grams of deionized water to the reactor, slowly add 1.5 grams of diethylene glycol butyl ether, stir to disperse and dissolve; then slowly add 2.5 grams of 2-methyl-2,4-pentanediol, stir to disperse and dissolve; Then slowly add 2.5 grams of DOW EH-9 isomeric alcohol polyoxyethylene ether, fully react, disperse and dissolve to a uniform transparent liquid; then slowly add 0.5 g of octylphenol polyoxyethy...

Embodiment 2

[0053] S1. Configure the first mixed solution:

[0054] Its ingredients and dosage are as follows:

[0055] Organic solvents:

[0056] Diethylene glycol butyl ether 2.5g

[0057] 2-Methyl-2,4-pentanediol 2.5g

[0058] Nonionic Surfactants:

[0059] Octylphenol ethoxylate 2.5g

[0060] Isodecanol Polyoxyethylene Ether 1.5g

[0061] Anionic surfactants:

[0062] Triethanolamine dodecylbenzenesulfonate 4.5g

[0063] DOW C10L Alkyl Diphenyl Ether Sulfonate 3.5g

[0064] Sodium xylene sulfonate 3g

[0065] Preparation process: Add 100 grams of deionized water to the reactor, slowly add 2.5 grams of diethylene glycol butyl ether, stir to disperse and dissolve; then slowly add 2.5 grams of 2-methyl-2,4-pentanediol, stir to disperse and dissolve; Then slowly add 2.5 grams of octylphenol polyoxyethylene ether, fully react, disperse and dissolve to a uniform transparent liquid; then slowly add 1.5 grams of isomeric decanol polyoxyethylene ether, fully react, disperse and dissolve...

Embodiment 3

[0069] S1. Configure the first mixed solution:

[0070] Its ingredients and dosage are as follows:

[0071] Organic solvents:

[0072] Diethylene glycol butyl ether 2.5g

[0073] Dipropylene glycol dimethyl ether 3g

[0074] Nonionic Surfactants:

[0075] Isodecanol polyoxyethylene ether 2.5g

[0076] Isomerized tridecyl alcohol polyoxyethylene ether 1.5g

[0077] Anionic surfactants:

[0078] Ethanolamine dodecylbenzenesulfonate 4.5g

[0079] Sodium dihexyl succinate monosulfonate 3.5g

[0080] Clariant SAS-60 Sodium Secondary Alkyl Sulfonate 3g

[0081] Preparation process: Add 100 grams of deionized water to the reaction kettle, slowly add 2.5 grams of diethylene glycol butyl ether, stir to disperse and dissolve; then slowly add 3 grams of dipropylene glycol dimethyl ether, stir to disperse and dissolve; then slowly add isomerized ten 2.5 grams of alcohol polyoxyethylene ether, fully react, disperse and dissolve to a uniform transparent liquid; then slowly add 1.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com