Clostridium tyrobutyricum for reducing content of n-butyl alcohol in Baijiu fermentation process

A technology of clostridium tyrobutyricum and starter, which is applied in the field of clostridium tyrobutyricum, can solve the problems of uncontrollable influence on the safety of wine body and flavor, and achieve the effect of reducing and controlling the content of n-butanol and increasing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Isolation and Identification of Pit Mud Microorganisms

[0034] Weigh 5g of pit mud sample into 100mL RCM liquid medium with glass beads, shake well, heat-treat at 80°C for 10min to eliminate non-spore bacteria, and anaerobically culture at 37°C for 4-7d; The supernatant was centrifuged at 4°C and 12,000rpm for 5min, and the supernatant was taken; the supernatant was serially diluted for 10 -2 、10 -3 、10 -4 、10 -5 、10 -6 , absorb 0.1mL of each gradient bacterial solution and spread it on the RCM medium, and culture it anaerobically at 37°C for 2-5 days; pick colonies of different shapes to streak on the RCM solid medium, and then culture them anaerobically at 37°C 4-7 days until colonies grow; follow the above steps to streak and isolate 3 times to obtain single colonies of each strain.

[0035] Pick a single colony on the plate and inoculate it into 8-10mL RCM liquid medium, and culture it anaerobically at 37°C for 24-28 hours to obtain the bacterial so...

Embodiment 2

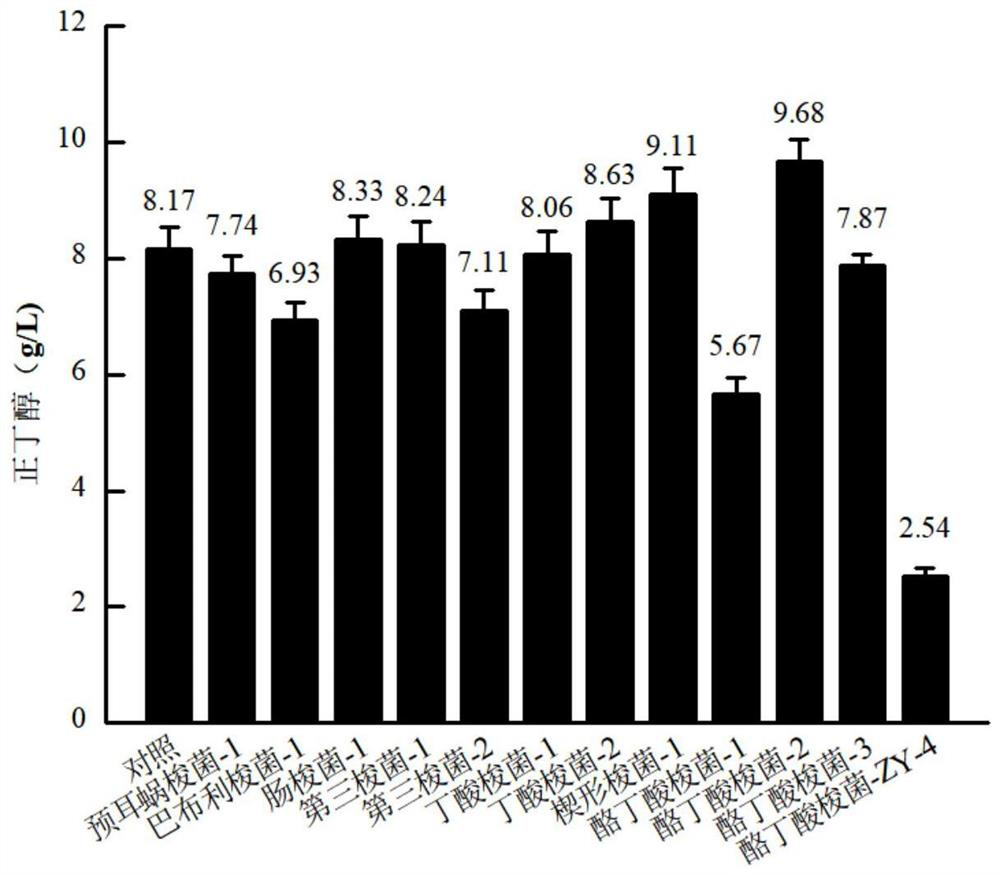

[0040] Example 2: Screening for reducing n-butanol production strains of Clostridium beijerinckii 6Y-1

[0041] Introduce the strains of the identified strains into RCM liquid medium for anaerobic culture at 37°C for 24-28h to OD 600 1.1, each strain was mixed with Clostridium beijerinckii 6Y-1 with the strongest n-butanol synthesis ability at an inoculation ratio of 10:1 by volume, and then inserted into the fermentation medium. culture medium. All were inoculated into the butanol fermentation medium with an inoculum amount (after mixing) of 10% (10 mL / 100 mL) of the volume of the butanol medium, and cultured anaerobically at 37° C. for 3 days. An internal standard (tert-amyl alcohol with a final concentration of 10 mg / L) was added to the fermentation broth, mixed evenly and then tested.

[0042] Compared with only adding Clostridium bejejerinckii 6Y-1 control, adding Clostridium tyrobutyricum ZY-4 can reduce the content of n-butanol by 68.91% ( figure 1 ).

Embodiment 3

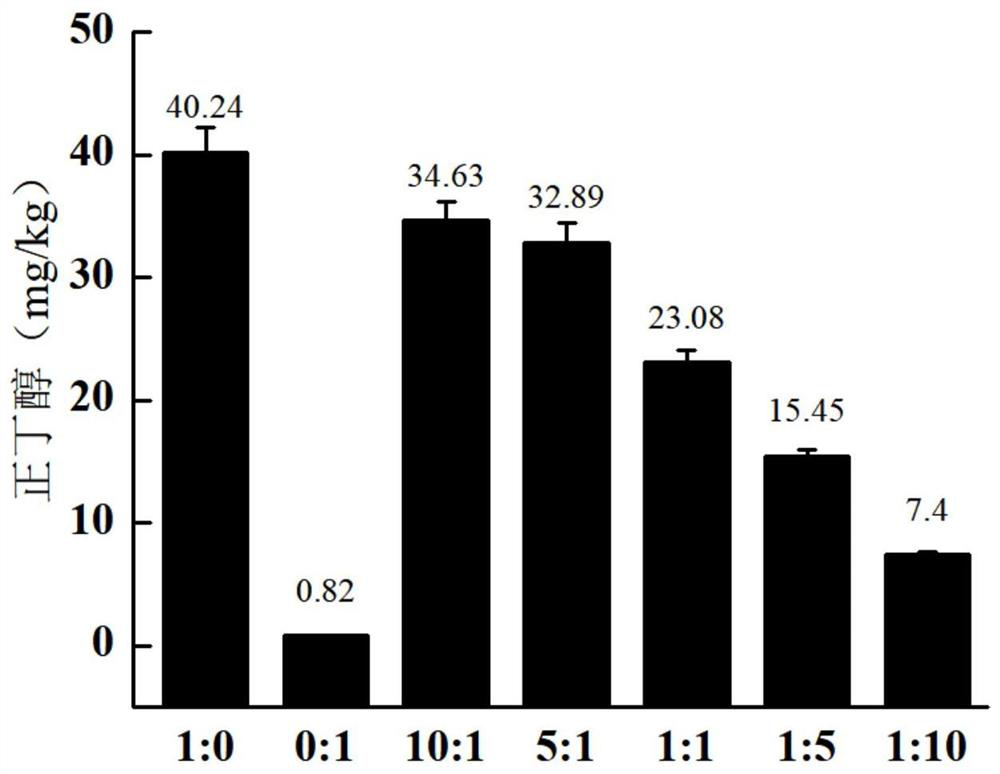

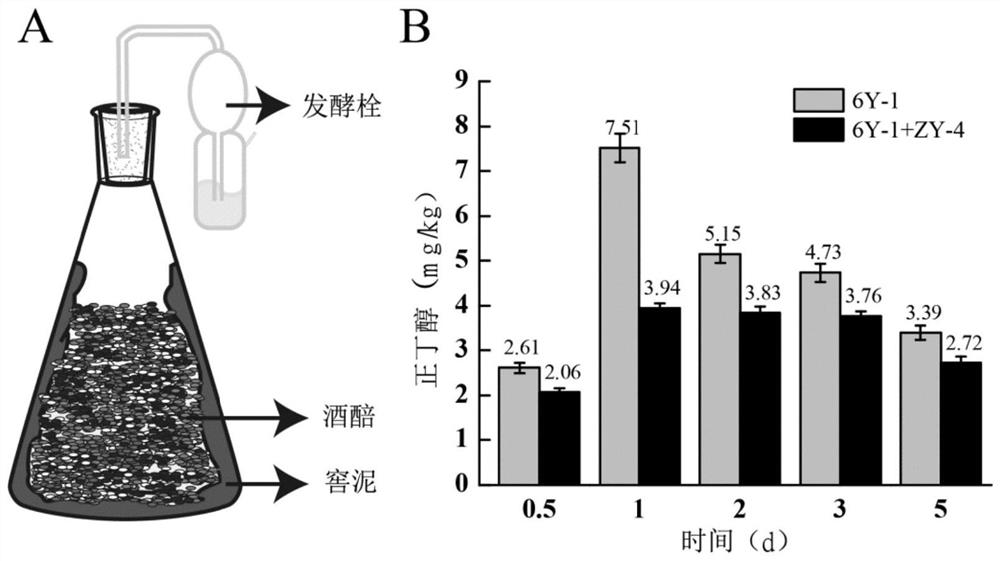

[0043] Example 3: Analysis of the reduction and control mechanism of Clostridium tyrobutyricum ZY-4 in the butanol medium system

[0044] Clostridium tyrobutyricum ZY-4 with a reduction effect and high butanol-producing Clostridium beijerinckii 6Y-1 were mixed at an inoculation ratio of 10:1 by volume and then inserted into the butanol fermentation medium, and the butanol medium After the inoculum amount of 10% of the volume was inoculated, cultured anaerobically at 37°C for 3 days. The butanol content and by-products, including acetic acid, butyric acid, ethanol and acetone, generated from glucose, an important precursor, were determined by gas chromatography and high performance liquid chromatography, respectively.

[0045] The study of the downregulation mechanism was carried out in the butanol medium with glucose as the precursor. Compared with the control that only added Clostridium beijerinckii 6Y-1, the addition of Clostridium tyrobutyricum ZY-4 could reduce the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com