A kind of composite microcapsule of oxymatrine and tributyrin and its preparation method and application

A technology of tributyrin and oxymatrine, applied in application, microcapsule, drug combination, etc., can solve problems such as harm to human health, lack of weaned piglets, antibiotic residues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

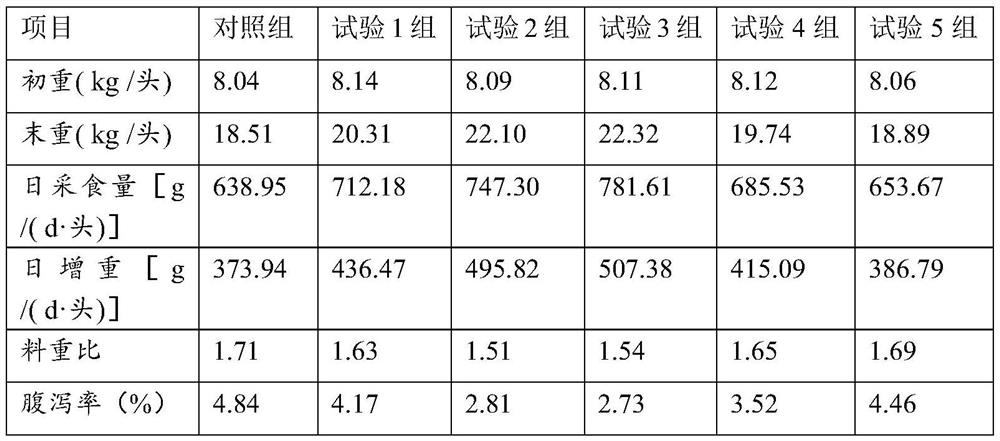

Examples

Embodiment 1

[0026] The preparation method of oxymatrine-tributyrin composite microcapsule A, the method comprises the steps:

[0027] Step 1, prepare the core material: Dissolve 1g of oxymatrine in 2mL of deionized water, then filter through a 0.22μm filter membrane, and then filter the filtered aqueous solution of oxymatrine and liquid tributyrin according to the volume ratio of 1:19 Mix and emulsify with a high shear emulsifier at 16 000 rpm for 10 min to obtain a core material. Among them, the mass ratio of oxymatrine to liquid tributyrin is 1:15.7.

[0028] Step 2, capsule material preparation: mix maltodextrin and sodium starch octenyl succinate with a mass ratio of 1:1, add to deionized water, and stir in a water bath at 60°C until dissolved to obtain maltodextrin and octenyl Starch sodium starch succinate total concentration (mass percentage concentration) is 30% aqueous solution, as capsule material.

[0029] Step 3, prepare the core capsule mixture: according to the mass ratio ...

Embodiment 2

[0032] The preparation method of oxymatrine-tributyrin composite microcapsule B comprises the following steps:

[0033] Step 1, prepare the core material: Dissolve 1 g of oxymatrine in 3 mL of deionized water, then filter it with a 0.22 μm filter membrane, and then make the filtered aqueous solution of oxymatrine and liquid tributyrin in a volume ratio of 1: 9 mixed and emulsified with a high shear emulsifier at 13,000 rpm for 15 minutes to obtain a core material. Among them, the mass ratio of oxymatrine to liquid tributyrin is 1:8.9.

[0034] Step 2, capsule material preparation: Add maltodextrin and sodium starch octenyl succinate with a mass ratio of 1:2 to deionized water, and stir in a water bath at 70°C until dissolved to obtain maltodextrin and octenyl starch The total concentration (mass percentage concentration) of starch sodium succinate is 20% aqueous solution, as the capsule material.

[0035] Step 3, prepare the core capsule mixture: according to the core materi...

Embodiment 3

[0038] The preparation method of oxymatrine-tributyrin composite microcapsule C, the method comprises the steps:

[0039] Step 1, prepare the core material: Dissolve 1g of oxymatrine in 4mL of deionized water, then filter it with a 0.22μm filter membrane, and then make the filtered aqueous solution of oxymatrine and liquid tributyrin in a volume ratio of 1: 4 Mix and emulsify for 20 minutes at 10,000 rpm with a high-shear emulsifier to obtain a core material. Among them, the mass ratio of oxymatrine to liquid tributyrin is 1:3.6.

[0040] Step 2, capsule material preparation: Add maltodextrin and sodium starch octenyl succinate with a mass ratio of 1:3 to deionized water, and stir in a water bath at 80°C until dissolved to obtain maltodextrin and octenyl starch The total concentration (mass percentage concentration) of starch sodium succinate is 25% aqueous solution, and the capsule material is obtained.

[0041] Step 3, prepare the core capsule mixture: according to the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com