Method for producing epoxide by adopting suspended bed reactor

A technology of epoxy and reactor, applied in chemical instruments and methods, chemical/physical processes, organic chemistry, etc., can solve the problem of uneven distribution of reactants and heat, difficulty in catalyst loading, poor mass transfer and heat transfer efficiency, etc. problems, to avoid local overheating of the reaction, good mass and heat transfer effects, and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

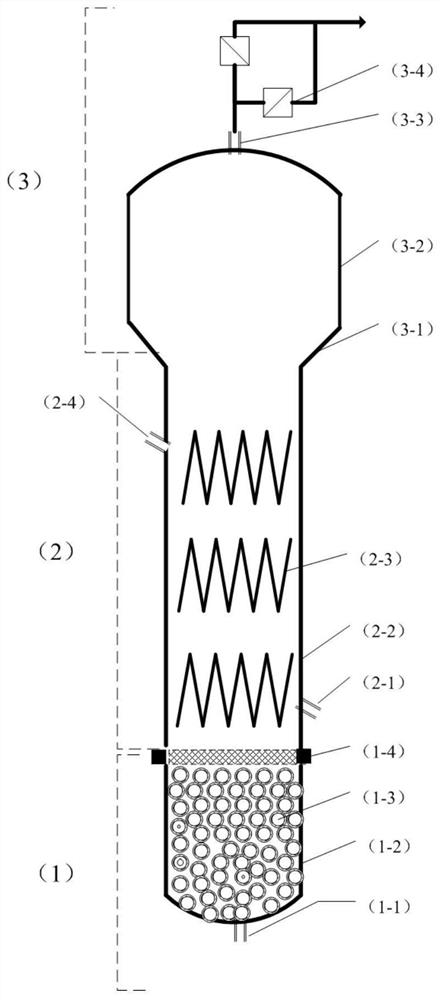

[0031] like figure 1 As shown, the suspended bed reactor has a cylinder diameter of 55 mm and a height of 100 mm. The premixing section (1) is provided with a baffle, and the distributor is a silicon carbide sintered plate with a porosity of 35% and a pore diameter of 90 μm; the cylinder diameter of the reaction section is 55 mm , height 600mm, catalyst inlet and catalyst outlet are located at 50mm above and below the reaction section respectively, a single set of serpentine heat exchange coils are installed in the reaction section, with a diameter of 6mm and a height of 350mm; the diameter of the separation section is 90mm and a height of 100mm , The filter pore size of the position separation component is 20 μm.

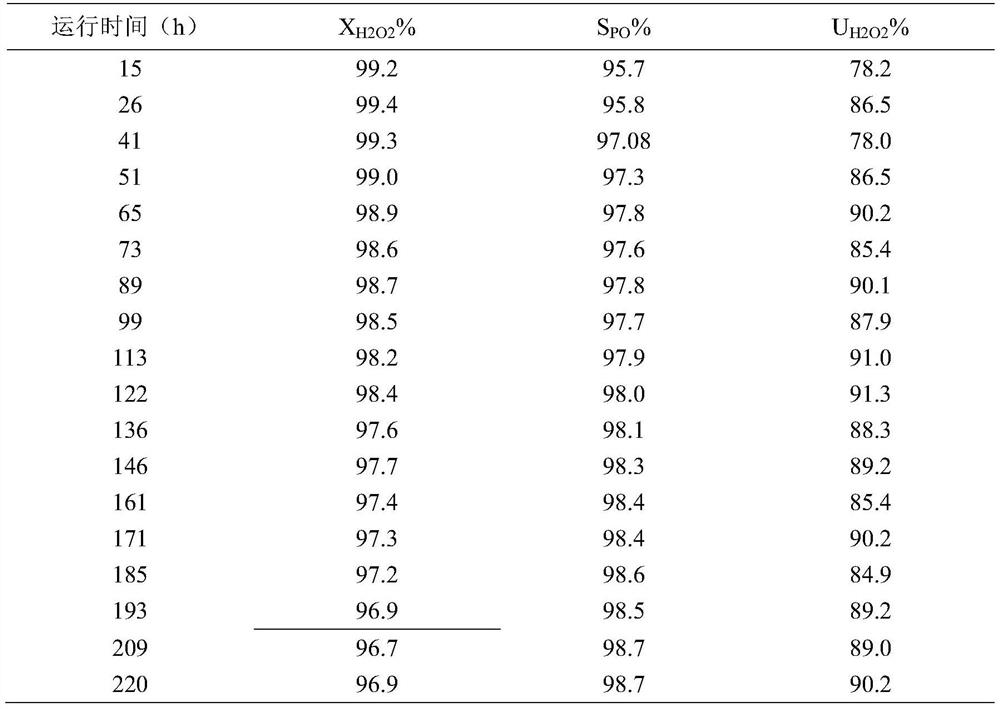

[0032] The microsphere TS-1 catalyst that 210g diameter is about 100 μm is packed into reactor reaction section by vacuum feed pump, and TS-1 content is 85wt% in the catalyzer; Propylene, hydrogen peroxide (50wt%) and methanol solvent enter from the reactor The fe...

Embodiment 2

[0041] Suspended bed reactor is with embodiment 1;

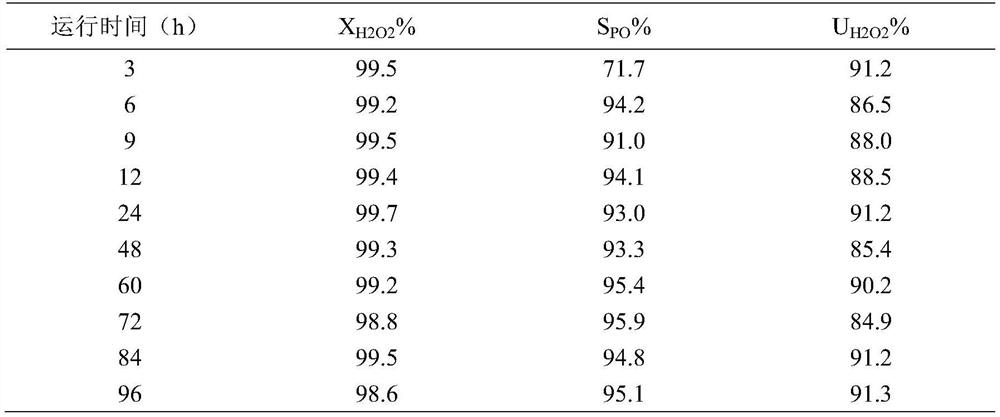

[0042] The microsphere TS-1 catalyst that 210g diameter is left and right sides of 100 μ m is packed into reactor reaction section by feeding pump, and TS-1 content is 85wt% in the catalyzer; 1-butene, hydrogen peroxide (50wt%) and methanol solvent from the The feed port enters, the premixing section enters the reaction section through the distribution plate after mixing, the heat generated by the reaction is removed from the reaction area through the built-in heat exchange component, and the reaction temperature is maintained between 35-45°C; after the reaction, the material enters the separation section and is separated from the catalyst Then it flows out from the discharge port, the catalyst stays in the reaction section, the molar ratio of 1-butene, methanol and hydrogen peroxide (50wt%) is 1:2.9:0.18, and the linear velocity of the material flowing in the reaction section is 0.39m / h. Product and raw material analysis ar...

Embodiment 3

[0046] Suspended bed reactor is with embodiment 1;

[0047] 210g of microsphere TS-1 catalysts with a diameter of about 100 μm are loaded into the reactor reaction section by a vacuum feed pump, and the TS-1 content in the catalyst is 85wt%; 1-butene, hydrogen peroxide (50wt%) and methanol solvent from the reaction The feed port of the pre-mixing section enters the reaction section through the distribution plate after mixing in the pre-mixing section. The heat generated by the reaction is moved out of the reaction zone through the built-in heat exchange component, and the reaction temperature is maintained between 38-45°C; After the catalyst is separated, it flows out from the discharge port, and the catalyst stays in the reaction section. The molar ratio of 1-butene, methanol and hydrogen peroxide (50wt%) is 1:6.3:0.25, and the linear velocity of the material flowing in the reaction section is 0.39m / h. Product and raw material analysis are the same as in Example 1. The resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com