Ester-ether copolymerization low-bleeding type polycarboxylate superplasticizer and preparation method thereof

A technology of ester ether copolymerization and polycarboxylic acid, which is applied in the field of construction admixtures, can solve the problems of high water retention polycarboxylate superplasticizer, low cost performance, complex reaction conditions and reaction process, low reaction conversion rate, etc., and achieve good concrete retention Slump effect, good cement adaptability and material adaptability, and the effect of improving the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

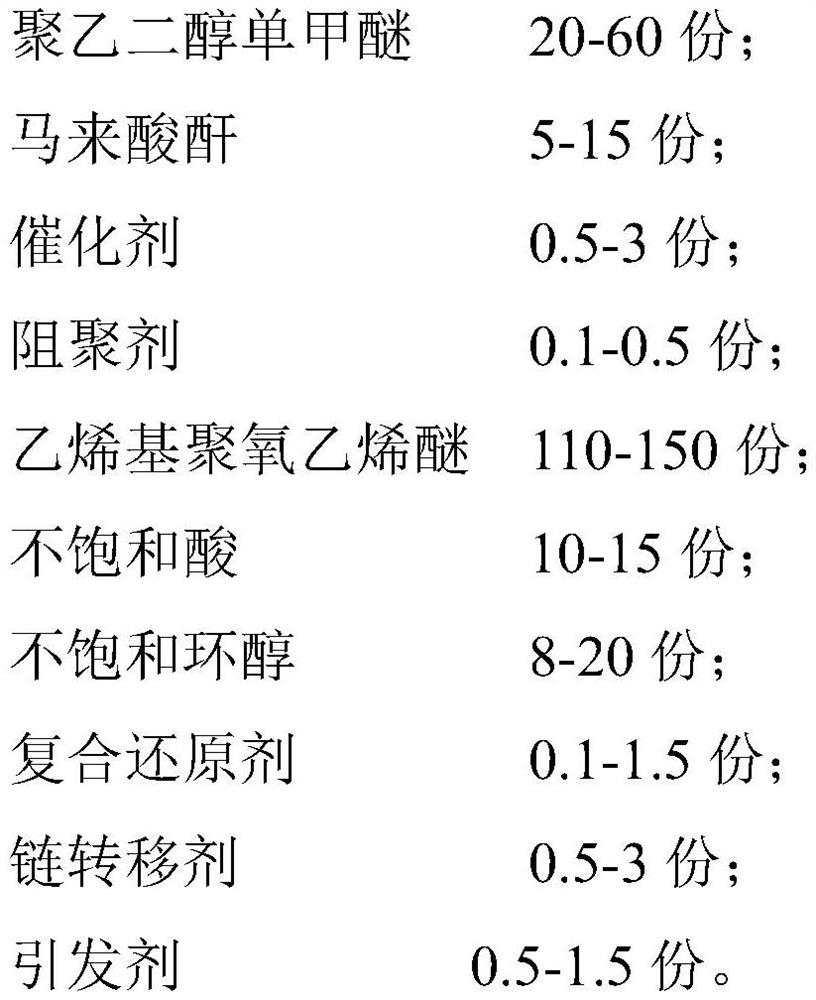

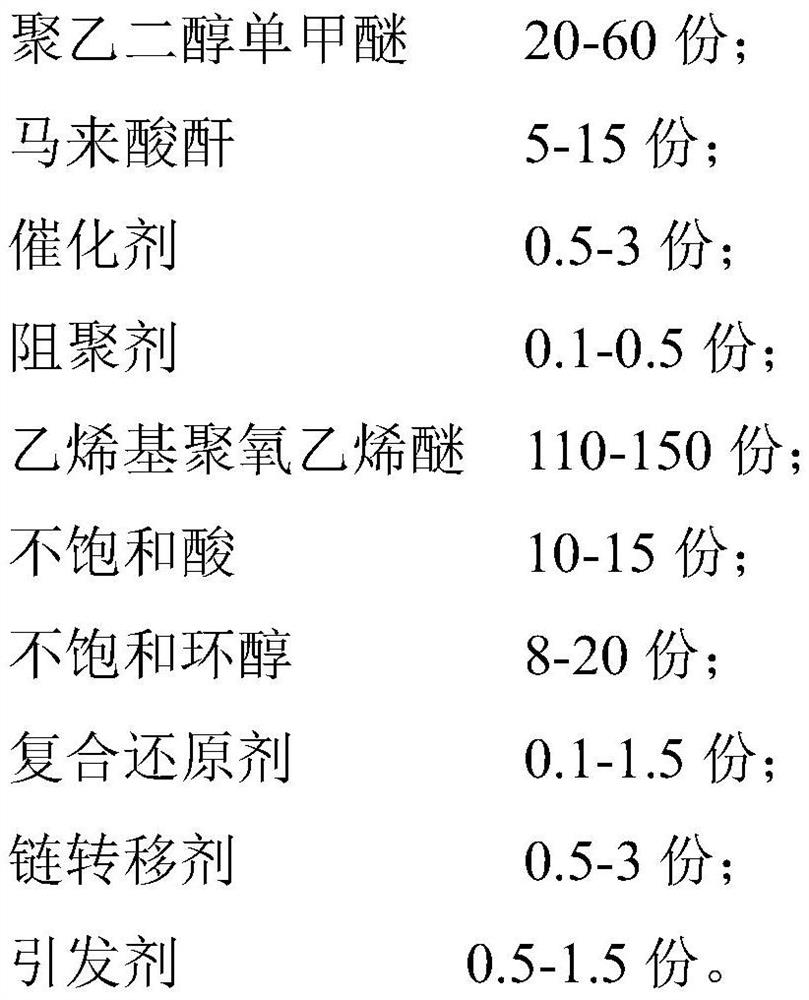

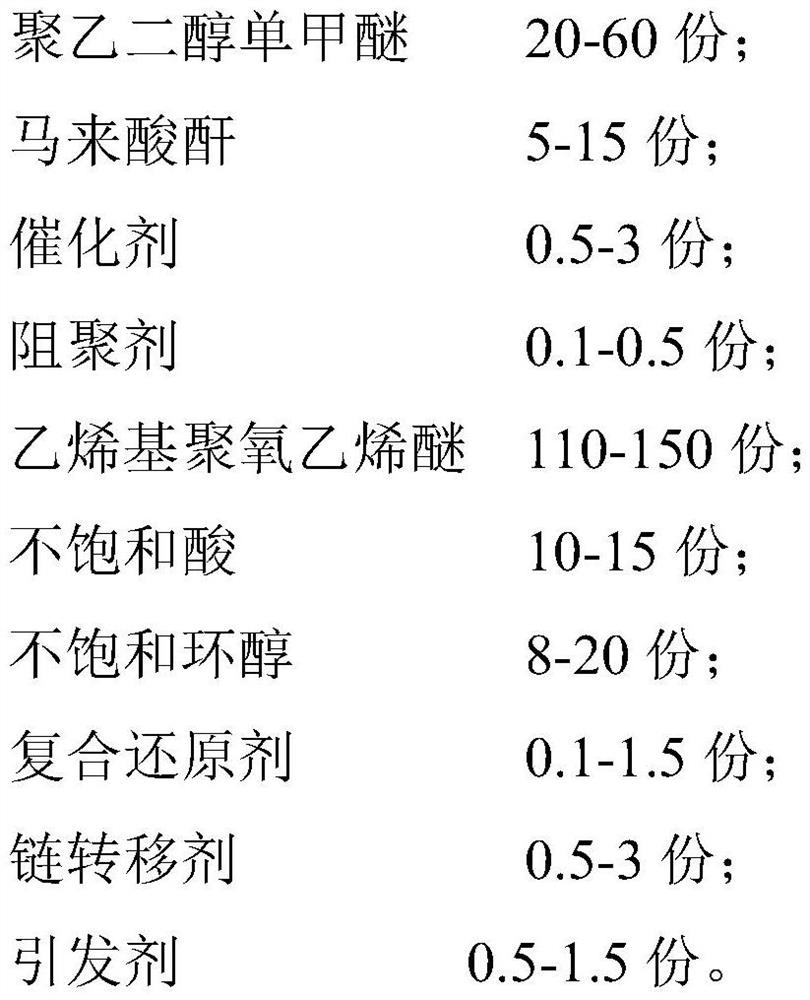

[0043] Configure the first mixed solution and the second mixed solution respectively, and the ratio is as follows:

[0044] The first mixed solution: methacrylic acid (15 parts) + ethylene cyclohexanol (3 parts) + 1,2-dimethyl-3-(1-methylvinyl) cyclopentanol (6 parts) + water (30 share)

[0045] The second mixed solution: thioglycolic acid (1.2 parts)+L~ascorbic acid (0.2 parts)+sodium hypophosphite (0.5 parts)+water (40 parts)

[0046] (1) Mix 30 parts of polyethylene glycol monomethyl ether, 8 parts of maleic anhydride, 0.5 parts of concentrated sulfuric acid, and 0.1 part of p-hydroxyanisole, heat up to 160°C-180°C, stir and vacuumize at the same time to make it React under a vacuum of 0.3MPa-0.5MPa for 5-7 hours. After the reaction is completed, add 160 parts of deionized water, cool down to below 60°C, and obtain an aqueous esterified monomer solution;

[0047] (2) Add 145 parts of vinyl polyoxyethylene ethers to the above-mentioned aqueous esterified monomer solution f...

Embodiment 2

[0051] Configure the first mixed solution and the second mixed solution respectively, and the ratio is as follows:

[0052] The first mixed solution: methacrylic acid (12 parts) + ethylene cyclohexanol (6 parts) + 1,2-dimethyl-3-(1-methylvinyl) cyclopentanol (7 parts) + water (30 share)

[0053] The second mixed solution: thioglycolic acid (1.2 parts)+L~ascorbic acid (0.2 parts)+sodium hypophosphite (0.5 parts)+water (40 parts)

[0054] (1) Mix 30 parts of polyethylene glycol monomethyl ether, 8 parts of maleic anhydride, 0.5 parts of concentrated sulfuric acid, and 0.1 part of p-hydroxyanisole, heat up to 160°C-180°C, stir and vacuumize at the same time to make it React under a vacuum of 0.3MPa-0.5MPa for 5-7 hours. After the reaction is completed, add 160 parts of deionized water, cool down to below 60°C, and obtain an aqueous esterified monomer solution;

[0055] (2) Add 145 parts of vinyl polyoxyethylene ethers to the above-mentioned aqueous esterified monomer solution f...

Embodiment 3

[0059] Configure the first mixed solution and the second mixed solution respectively, and the ratio is as follows:

[0060] The first mixed solution: methacrylic acid (12 parts) + ethylene cyclohexanol (6 parts) + 1,2-dimethyl-3-(1-methylvinyl) cyclopentanol (7 parts) + water (30 share)

[0061] The second mixed solution: thioglycolic acid (1.2 parts)+L~ascorbic acid (0.2 parts)+sodium hypophosphite (0.5 parts)+water (40 parts)

[0062] (1) Mix 40 parts of polyethylene glycol monomethyl ether, 10 parts of maleic anhydride, 0.6 parts of concentrated sulfuric acid, and 0.1 part of p-hydroxyanisole, heat up to 160°C-180°C, stir and vacuumize at the same time to make it React under a vacuum of 0.3MPa-0.5MPa for 5-7 hours. After the reaction is completed, add 160 parts of deionized water, cool down to below 60°C, and obtain an aqueous esterified monomer solution;

[0063] (2) Add 135 parts of vinyl polyoxyethylene ethers to the above-mentioned aqueous esterified monomer solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com