Perishable organic solid waste biological drying strain and application thereof

A technology of organic solid waste and solid microbial agent, applied in the field of environmental microorganisms, can solve the problems of short high temperature duration, poor drying effect, and few types of high-efficiency functional microorganisms, and achieve the effect of strong self-heating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The third aspect of the present invention provides the preparation method of the liquid microbial agent, at least including the following steps: making Geobacillus thermophilic Geobacillus kaustophilus The pure strain of FWGK-JYJ1 is inoculated in the liquid medium for cultivation, and the liquid bacterial agent is obtained after the cultivation is completed.

[0045] In one embodiment, the Geobacillus thermophilus Geobacillus kaustophilus After the pure strain of FWGK-JYJ1 is inoculated into a liquid medium for cultivation, the obtained culture solution is then inoculated into another liquid medium for expanded cultivation, and a liquid bacterial agent is obtained after the cultivation is completed.

[0046] In one embodiment, the temperature of cultivation is 40-60°C.

[0047] In one embodiment, the stirring speed of the cultivation is 150-230 r / min.

[0048] In one embodiment, the Geobacillus thermophilus Geobacillus kaustophilus The pure strain of FWGK-JYJ1 was i...

Embodiment 1

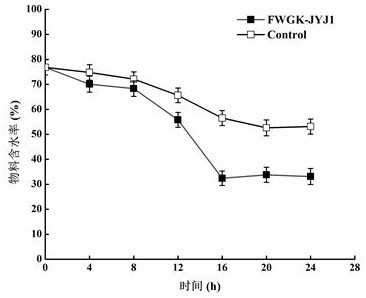

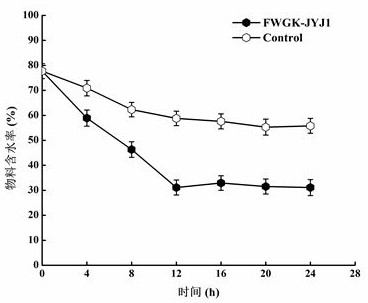

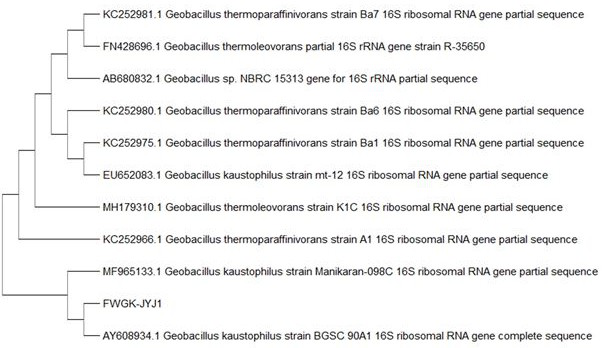

[0069] Example 1: Isolation, screening and performance determination of bacterial strain FWGK-JYJ1

[0070] The separation and purification process of the bacterial strain FWGK-JYJ1 of the present invention: the test sample was collected from a high-temperature aerobic fermentation tank of a catering waste treatment plant, mixed with sterile water, and then diluted in a gradient, and 200 μL of dilutions of different gradients were applied to the After culturing in a constant temperature incubator at 50 °C for 24-48 hours on the separation and purification medium plate, single colonies with different shapes and sizes were picked, streaked and purified, and numbered and preserved. A total of 41 strains were obtained through preliminary screening.

[0071] The strains obtained from the primary screening were re-screened at the highest growth temperature, and the strains were streaked on the solid medium and placed in an incubator with a temperature gradient of 50, 55, 60, 65, 70, ...

Embodiment 2

[0074] Embodiment 2: the bacterial agent preparation of bacterial strain FWGK-JYJ1

[0075] Preparation of liquid bacterial agent: Inoculate the pure strain of FWGK-JYJ1 into five 10 mL seed culture medium, culture in a constant temperature shaker at 50 °C and 180 r / min for 12 h, and then add 1 volume of the liquid culture medium % of the inoculum was inserted into 5 L liquid medium for expansion and cultured at 50 °C and 180 r / min for 18 h to obtain the liquid inoculum of the strain.

[0076] Preparation of solid bacterial agent: it is prepared by mixing starch and liquid bacterial agent of the strain according to the mass ratio of 1:5, and spray drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com