Preparation method of silicon-oxygen negative electrode material of lithium ion battery, negative electrode material and lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of large volume expansion, poor electrical conductivity, and low first cycle efficiency, and achieve high porosity and interlayer structure. Stable, easy-to-use equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

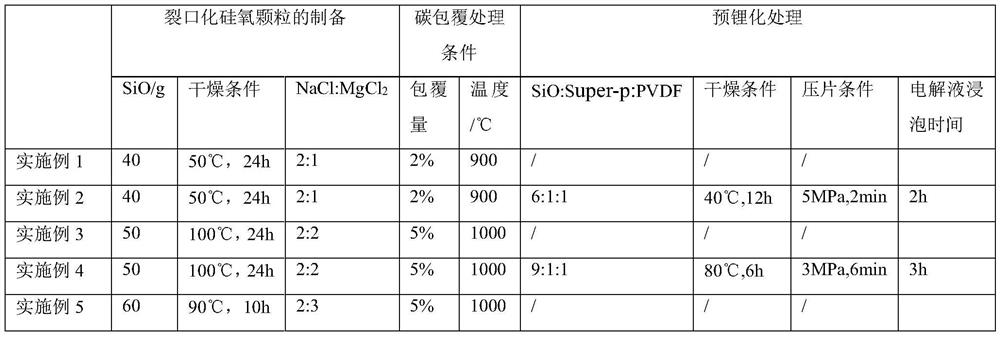

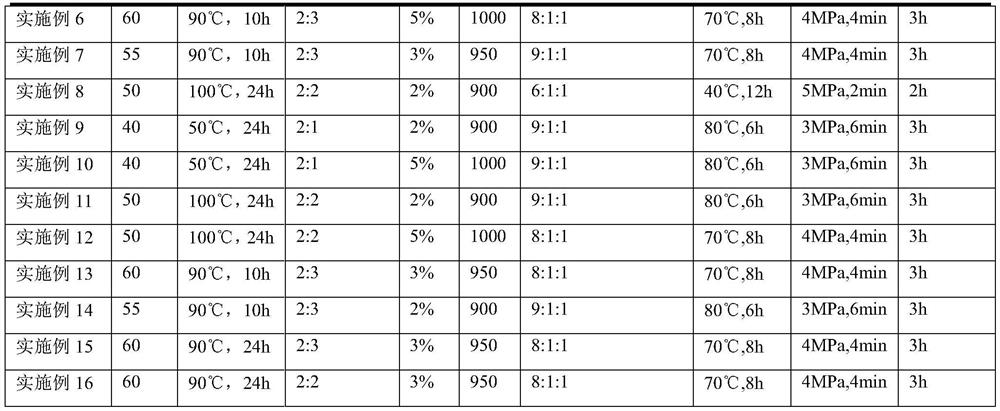

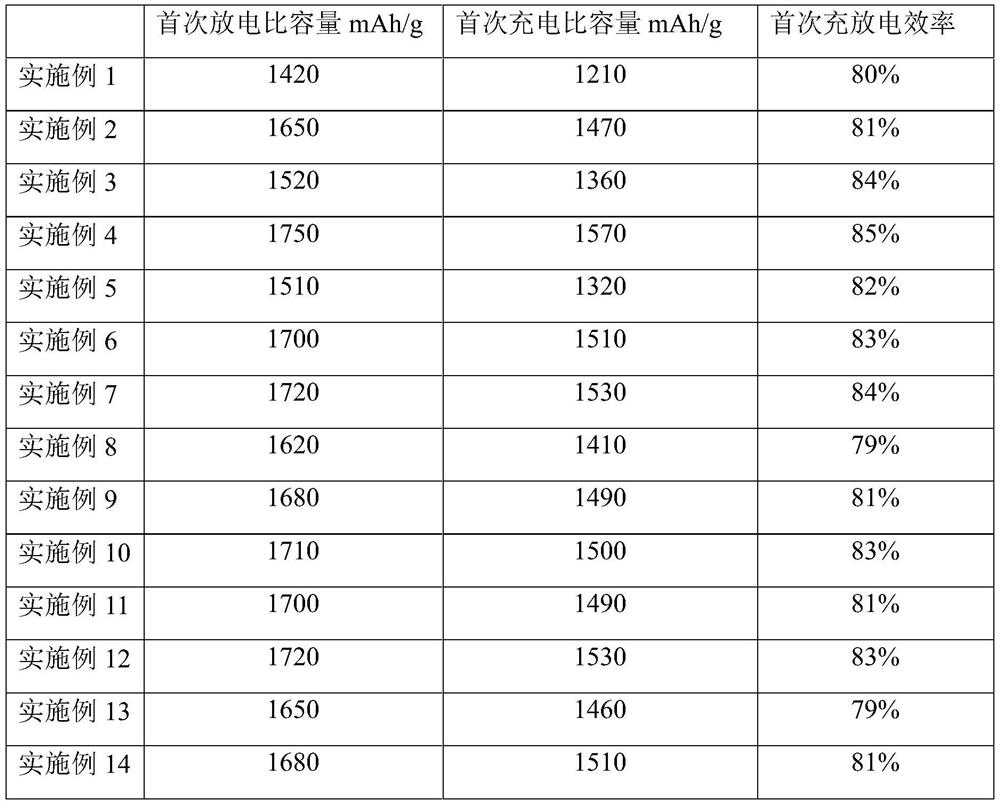

Examples

Embodiment 1

[0034] A method for preparing a lithium-ion battery silicon-oxygen negative electrode material, comprising the following steps:

[0035] (1) Preparation of cracked silica particles:

[0036] 1.1 Weigh 40g of SiO powder and add it to a 5:6:2 mixture of dimethyl sulfone, formamide, and polyethylene glycol, ultrasonically disperse for 24 hours; centrifuge, take out the silicon oxide particles, and place them in an oven at 50°C to dry for 24 hours. hours, to obtain intercalated silica particles;

[0037] 1.2 Add the intercalated silicon-oxygen particles into the molten 2:1 mixture of sodium chloride and magnesium chloride to disperse to obtain a molten mixture, which is rapidly frozen with liquid nitrogen to obtain a low-temperature mixture;

[0038] 1.3 The low-temperature mixture is rapidly heated by microwaves, so that the surface of the low-temperature mixture is cracked, cleaned and filtered, and cracked silicon oxide particles are obtained;

[0039] (2) Preparation of carb...

Embodiment 2

[0041] A method for preparing a lithium-ion battery silicon-oxygen negative electrode material, comprising the following steps:

[0042] (1) Preparation of cracked silica particles:

[0043] 1.1 Weigh 40g of SiO powder and add it to a 5:6:2 mixture of dimethyl sulfone, formamide, and polyethylene glycol, ultrasonically disperse for 24 hours; centrifuge, take out the silicon oxide particles, and place them in an oven at 50°C to dry for 24 hours. hours, to obtain intercalated silica particles;

[0044] 1.2 Add the intercalated silicon-oxygen particles into the molten 2:1 mixture of sodium chloride and magnesium chloride to disperse to obtain a molten mixture, which is rapidly frozen with liquid nitrogen to obtain a low-temperature mixture;

[0045] 1.3 The low-temperature mixture is rapidly heated by microwaves, so that the surface of the low-temperature mixture is cracked, cleaned and filtered, and cracked silicon oxide particles are obtained;

[0046] (2) Preparation of carb...

Embodiment 3

[0052] A method for preparing a lithium-ion battery silicon-oxygen negative electrode material, comprising the following steps:

[0053] (1) Preparation of cracked silica particles:

[0054] 1.1 Weigh 50g of SiO powder and add it to a 5:6:2 mixture of dimethyl sulfone, formamide, and polyethylene glycol, ultrasonically disperse for 24 hours; centrifuge, take out the silicon oxide particles, and place them in an oven at 100°C to dry for 24 hours. hours, to obtain intercalated silica particles;

[0055] 1.2 Add the intercalated silicon-oxygen particles into the molten 2:2 mixture of sodium chloride and magnesium chloride to disperse to obtain a molten mixture, and then freeze the molten mixture rapidly with liquid nitrogen to obtain a low-temperature mixture;

[0056] 1.3 The low-temperature mixture is rapidly heated by microwaves, so that the surface of the low-temperature mixture is cracked, cleaned and filtered, and cracked silicon oxide particles are obtained;

[0057] (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com