A kind of high flux composite membrane, its preparation method and application

A composite membrane, high-throughput technology, applied in chemical instruments and methods, membrane technology, life-saving equipment, etc., can solve the problems of portable products, inability to meet the standards of direct access to surface water for purification and drinking, and inability to remove them at the same time. achieve light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

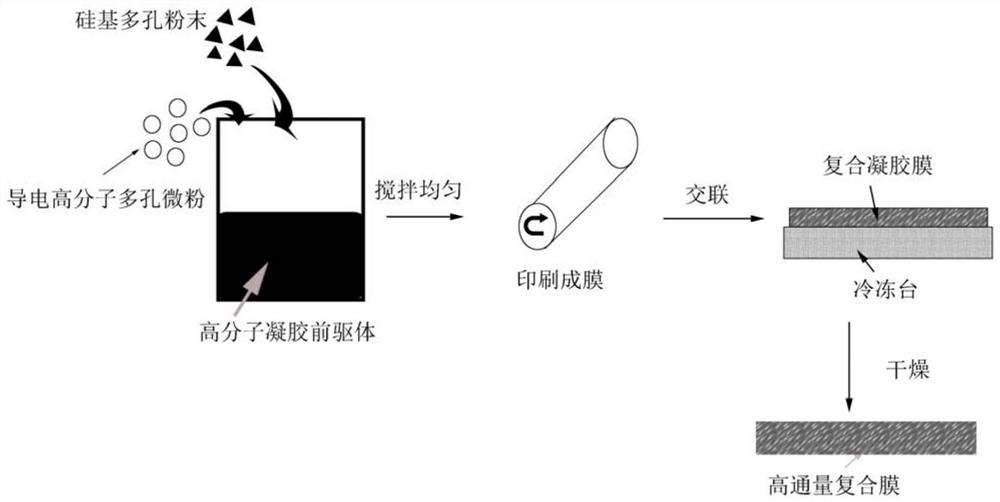

[0036] As an aspect of the technical solution of the present invention, it relates to a method for preparing a high-throughput composite membrane, which includes:

[0037] Uniformly disperse the conductive polymer porous material and silicon-based porous material in the polymer gel precursor to form a mixed solution;

[0038] Forming the mixed solution into a membrane structure, and performing a cross-linking treatment to form a composite gelled film;

[0039] The composite gelled film is subjected to directional freeze-thaw treatment, and then dried to obtain a high-throughput composite film.

[0040] In some preferred embodiments, the preparation method specifically includes:

[0041] (1) Dispersing conductive polymer porous micropowder and silicon-based porous powder in polymer gel precursor;

[0042] (2) After the above solution is stirred evenly, it is printed into a film, cross-linked, and forms a composite gelled film;

[0043] (3) Directly freeze-thaw the above-ment...

Embodiment 1

[0082] (1) Preparation of composite precursor: 1 g polypyrrole airgel micropowder (diameter range 500 nm-300 microns, specific surface area 1000 m 2 / g) and 99g mesoporous silica powder (size 1-500 micron, specific surface area 1200m 2 / g) dispersed in 200g polytetrafluoroethylene solution, mechanically stirred and mixed.

[0083] (2) Preparation of composite gelled film: Mix the above mixture evenly, prepare a composite film with a thickness of 500 μm by roller printing method, cure and cross-link at 120° C. to obtain a composite gelled film.

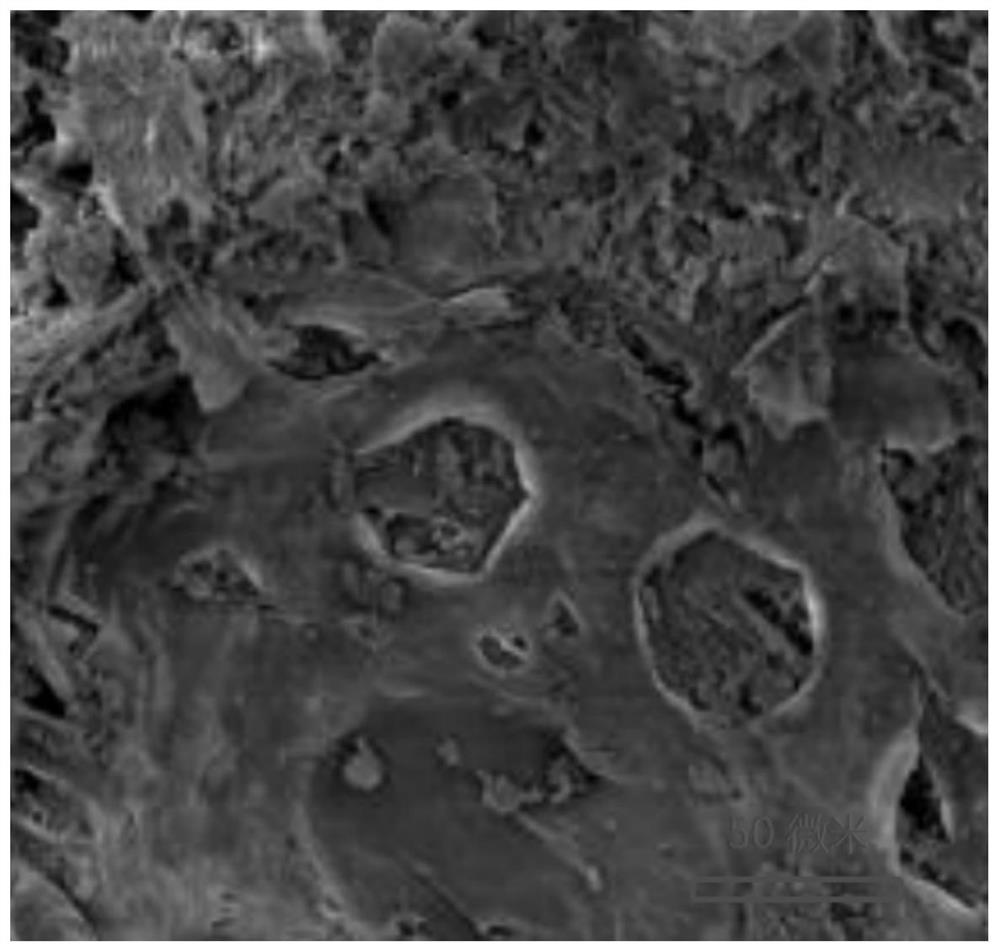

[0084] (3) The composite gelled film was spread on a metal freezing platform, frozen at -20°C for 5 hours, and then thawed, and repeated twice. Then use supercritical carbon dioxide to dry (the drying temperature is 35° C., and the drying pressure is 9 MPa), and dry for 10 hours to obtain a high-flux composite membrane. figure 1 It is a schematic diagram of the synthetic route of the high-flux composite membrane, figure 2 The scann...

Embodiment 2

[0086] (1) Preparation of composite precursor: 20g of polyaniline foam micropowder (diameter range 100nm-100micron, specific surface area 100m 2 / g) and 80g silica airgel powder (size 100-1000nm, specific surface area 820m 2 / g) was dispersed in 100 g of polystyrene toluene solution, and mixed by mechanical stirring.

[0087] (2) Preparation of composite gelled film: Mix the above mixture evenly, prepare a composite film with a thickness of 412 μm by roller printing method, cure and cross-link at 80° C. to obtain a composite gelled film.

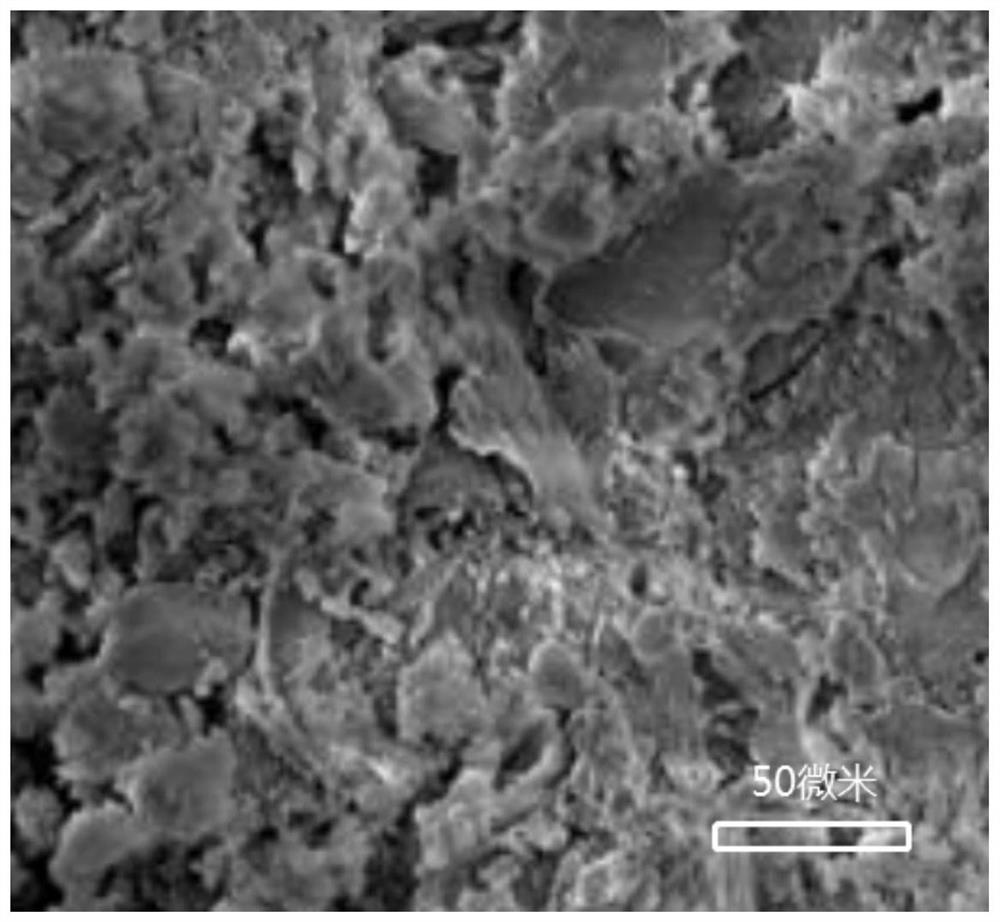

[0088] (3) The composite gelled film was spread on a metal freezing table, frozen at -40°C for 1 hour, and then thawed, and repeated 4 times. Drying under reduced pressure (at a drying temperature of 40° C.) for 60 minutes was then used to obtain a high-flux composite membrane. figure 1 It is a schematic diagram of the synthetic route of the high-flux composite membrane, image 3 The scanning electron microscope image of the obtained high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com