Method for efficiently recovering protein from excess sludge

A technology for excess sludge and protein, applied in the preparation method of peptides, plastic recycling, sludge treatment, etc., can solve the problems of unsuitable protein recovery, complex protein composition, low protein content, etc., to promote sludge dispersion, avoid Effects of overconsumption, rapid biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

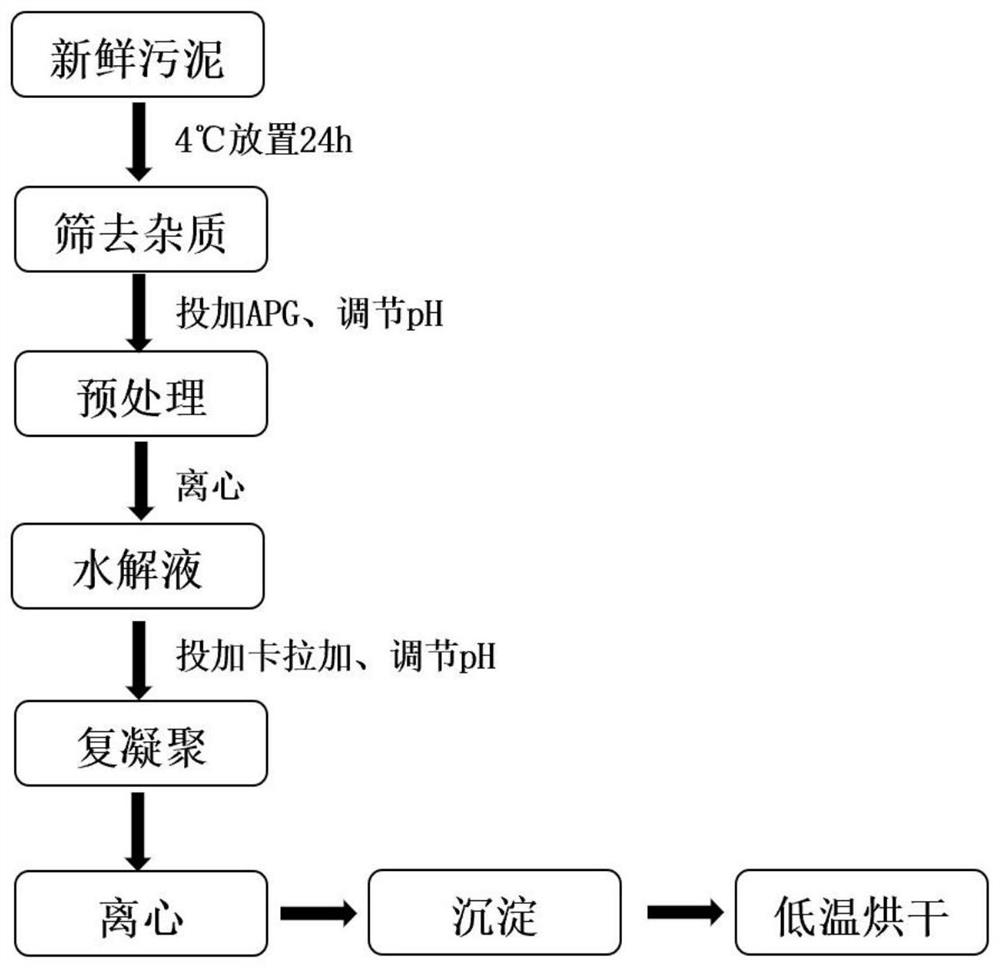

[0032]This embodiment is a method of efficiently recovering proteins from the remaining sludge (WAS), which includes the following steps:

[0033]The first step: sludge removed from the sewage treatment plant sludge, after 24 hours at 4 ° C, first discharge the supernatant with a straw, and filtered the sludge with a piece of aperture of 1 mm. The impurities in sludge were sieved, and finally the treated sludge was stored in a 4 ° C in an environment for subsequent experiments, and the SS of WAS was adjusted at around 10,000 mg / L, and the remaining sludge was obtained. This processing process is mainly to sieve the impurities in WAS and prepare for the back pre-processing.

[0034]Step 2: Take the residual sludge WAS in an anaerobic reactor having a capacitive volume of 500 ml, adjusting the pH of WAS 10.0 ± 0.2, then add 0.3 g / gs of APG at a temperature of 35 ± 1 ° C at a temperature of 35 ± 1 ° C. After the reaction, the reaction bottle was performed after 2-5 min, and the reaction ...

Embodiment 2

[0040]In the present embodiment, the present embodiment is in that, the amount of the APG in the present embodiment is added according to 0.1, 0.2, 0.4, 0.5 g / gs, and the recovery rate of the protein in this example is less than 90. %, But above 80%.

[0041]Under the conditions of the APG investment of 0.3 g / gss and pH of 10.0, the hydrolysis effect of WAS is preferably, the released protein content is high, which significantly improves the crack effect of sludge. Compared with the unprocessed sludge, the amount of SCOD of the APG was 0.0 ± 0.2, and the amount of SCOD of WAS was increased from 200.2 mg / L to 4500.0mg / L, protein dissolution amount. From 17.1 mg / L to 1009.7 mg / l, the amount of polysaccharide increased from 10.7 mg / L to 663.9 mg / L, and the SCOD content was increased by 22.5 times, and the protein content was increased by 59.0 times, and the polysaccharide was increased by 61.87 times.

Embodiment 3

[0043]In the present embodiment, the present embodiment is in that the pre-processed time is 0, 4, 8, 12, 24, 32, 48h in the present embodiment. During the WAS hydrolysis process, the highest concentration of SCOD, protein and polysaccharide increases with an increase in APG investment, but changes over time. When the reaction time was 2 h, the highest concentration of SCOD, protein and polysaccharide was 3250.1, 798.9, 478.1 mg / L, and the blank group SCOD, protein and polysaccharide were only 200.2, 17.2, 10.9 mg / L. The amount of protein is reduced in the amount of protein in the reaction time than 8 h, which is not conducive to efficient recovery of proteins.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com