Polycarboxylate superplasticizer as well as preparation method and application thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of polycarboxylic acid water reducing agent and its preparation, can solve the problems of increasing labor cost, insufficient adaptability, waste of time and resources, etc., and achieves improved dispersion performance and fewer types of raw materials. , the effect of efficient synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

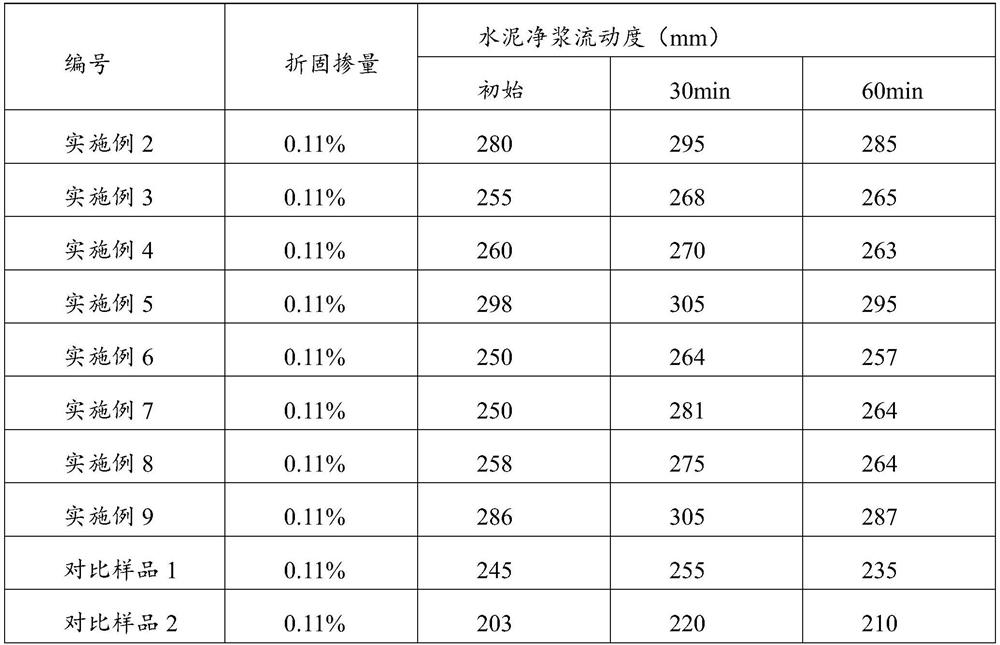

Examples

Embodiment 1

[0031] Embodiment 1 of the present invention is: a polycarboxylic acid water reducer, the synthetic raw materials include unsaturated polyoxyethylene ether (ethylene glycol monovinyl polyglycol ether, molecular weight is 3000), unsaturated acid (acrylic acid) , chain transfer agent (mercaptopropionic acid), 1% ferrous sulfate solution, hydrogen peroxide, E51 (produced by Germany Brüggemann), 30% liquid caustic soda and deionized water.

[0032] In percent by weight, the proportioning of synthetic raw materials is as follows:

[0033] Unsaturated polyoxyethylene ether (ethylene glycol monovinyl polyglycol ether, molecular weight 3000) 34%-38%;

[0034]

[0035]

[0036]A kind of preparation method of polycarboxylate superplasticizer of the present invention comprises the following steps:

[0037] 1. Put ethylene glycol monovinyl polyglycol ether, deionized water, hydrogen peroxide and 1% ferrous sulfate solution into the four-necked flask in sequence;

[0038] 2. Start ...

Embodiment 2

[0044] Embodiment 2 of the present invention is: a preparation method of polycarboxylate water reducer, comprising the following steps:

[0045] 1. Put 362.5g of ethylene glycol monovinyl polyglycol ether, 257.7g of deionized water, 3g of hydrogen peroxide and 1g of 1% ferrous sulfate solution into the four-necked flask successively;

[0046] 2. Start stirring, and add solution A and solution B dropwise at the same time, solution A is added dropwise for 35 minutes, and solution B is added dropwise for 45 minutes;

[0047] 3. After the dropwise addition, continue to react for 60 minutes;

[0048] 4. After the reaction, add 273.54g of water to the four-necked flask to dilute, then add 9.7g of liquid caustic soda to adjust the pH value to about 5-7, and finally obtain the polycarboxylate superplasticizer.

[0049] Specifically, solution A is an aqueous solution prepared by uniformly mixing 1.53g chain transfer agent (mercaptopropionic acid), 32.62g unsaturated acid (acrylic acid...

Embodiment 3

[0050] Embodiment 3 of the present invention is: a preparation method of polycarboxylate water reducer, comprising the following steps:

[0051] 1. Put 365.1g of ethylene glycol monovinyl polyglycol ether, 257.7g of deionized water, 3g of hydrogen peroxide and 1g of 1% ferrous sulfate solution into the four-necked flask successively;

[0052] 2. Start stirring, and add solution A and solution B dropwise at the same time, solution A is added dropwise for 40 minutes, and solution B is added dropwise for 50 minutes;

[0053] 3. After the dropwise addition, continue to react for 60 minutes;

[0054] 4. After the reaction, add 272.54g of water into the four-neck flask to dilute, then add 9.7g of liquid caustic soda to adjust the pH value to about 5-7, and finally obtain the polycarboxylate superplasticizer.

[0055] Specifically, solution A is an aqueous solution prepared by uniformly mixing 1.53g of chain transfer agent (mercaptopropionic acid), 30g of unsaturated acid (acrylic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com