Aqueous zinc ion battery electrolyte additive

An electrolyte additive, zinc-ion battery technology, applied in water-based electrolytes, secondary batteries, acidic electrolytes, etc., can solve the problems of insufficient site coverage, weak inhibition of hydrogen evolution reaction, weak molecular adsorption and binding force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for using an amino acid electrolyte additive:

[0028] The additive used in this embodiment is:

[0029]

[0030] Wherein m is 0, n is 1, wherein K2 (basic amino acid residue) is selected from arginine, that is, the additive is arginine of amino acids.

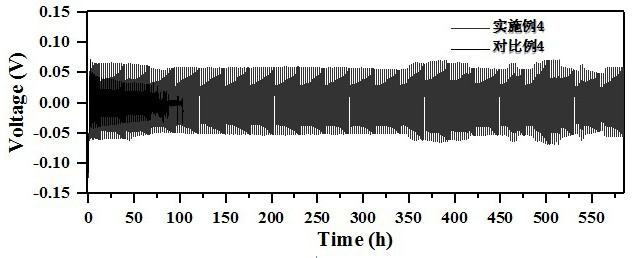

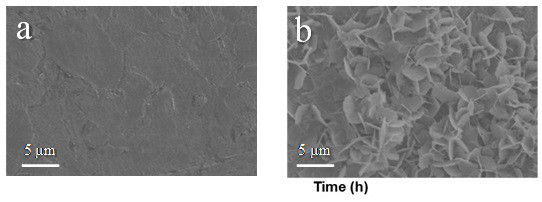

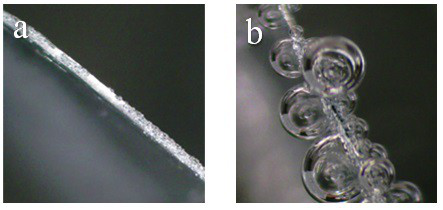

[0031] Dissolve 0.01 mol of arginine and 0.3 mol of zinc sulfate in deionized water to prepare 100 ml of electrolyte solution containing 3 mol / L zinc sulfate and 0.1 mol / L arginine. One of the Ti flakes / Zn flakes / Cu mesh was placed in the electrolyte as a current collector for the electrodeposition of zinc. The deposition morphology of zinc was as follows: figure 1 a, Zinc deposition without obvious dendrites. The zinc deposition was then observed in situ with an optical microscope, as shown in figure 2 a, It can be seen from the figure that there are no obvious bubbles during the deposition process, reflecting that the hydrogen evolution reaction is not obvious during the zinc d...

Embodiment 2

[0036] This example provides a method of using a lipopeptide electrolyte additive:

[0037] The additive used in this embodiment is:

[0038]

[0039] Where m is 1, and K1 is a saturated carbon chain in the fatty acid acyl chain, which corresponds to a fatty acid with a carbon number of 12, that is, a lauric acid acyl chain.

[0040] n is 4, wherein K2 (basic amino acid residue) is selected from lysine.

[0041] That is, the additive is a lipopeptide composed of lauric acid (containing 12 carbons) and 4 lysine polycondensed, which is abbreviated as C12K4 in this example (C12 refers to the acyl chain of lauric acid, and K refers to the residue of lysine).

[0042]Dissolve 0.001 mol of additive C12K4 and 0.1 mol of zinc sulfate in deionized water to prepare 100 ml of electrolyte solution containing 1 mol / L zinc sulfate and 0.01 mol / L lipopeptide. One of the Ti flakes / Zn flakes / Cu mesh was placed in the electrolyte as a current collector for the electrodeposition of zinc. Th...

Embodiment 3

[0044] This example provides a method of using a lipopeptide electrolyte additive:

[0045] The additive used in this embodiment is:

[0046]

[0047] Wherein m is 1, K1 is the saturated carbon chain in the fatty acid acyl chain, and its corresponding fatty acid carbon number is 24, namely the acyl chain of lignoceric acid.

[0048] n is 1, wherein K2 (basic amino acid residue) is selected from lysine.

[0049] That is, the additive is a lipopeptide formed by polycondensation of lignoceric acid (containing 24 carbons) and 1 lysine, which is abbreviated as C24K1 in this example (C24 refers to the acyl chain of lignoceric acid, and K1 refers to a lysine residue).

[0050] Dissolve 0.01 mol of additive C24K1 and 0.2 mol of zinc chloride in deionized water to prepare 100 ml of electrolyte solution containing 2 mol / L zinc chloride and 0.1 mol / L lipopeptide. One of the Ti sheet / Zn sheet / Cu mesh is placed in the electrolyte as a current collector for zinc electrodeposition, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com