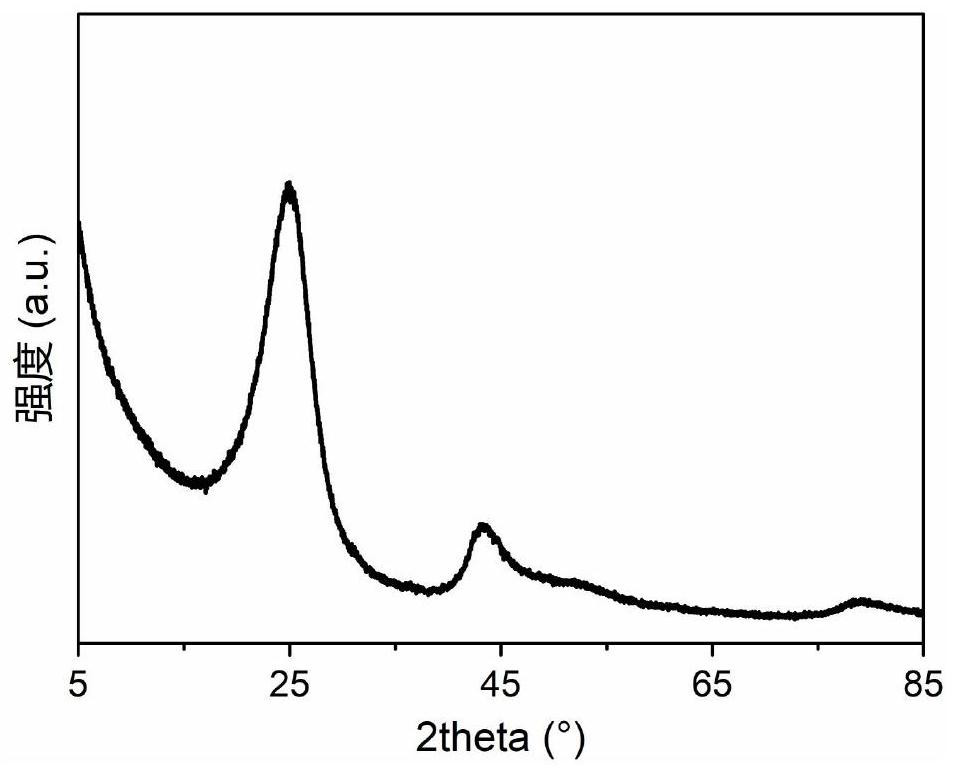

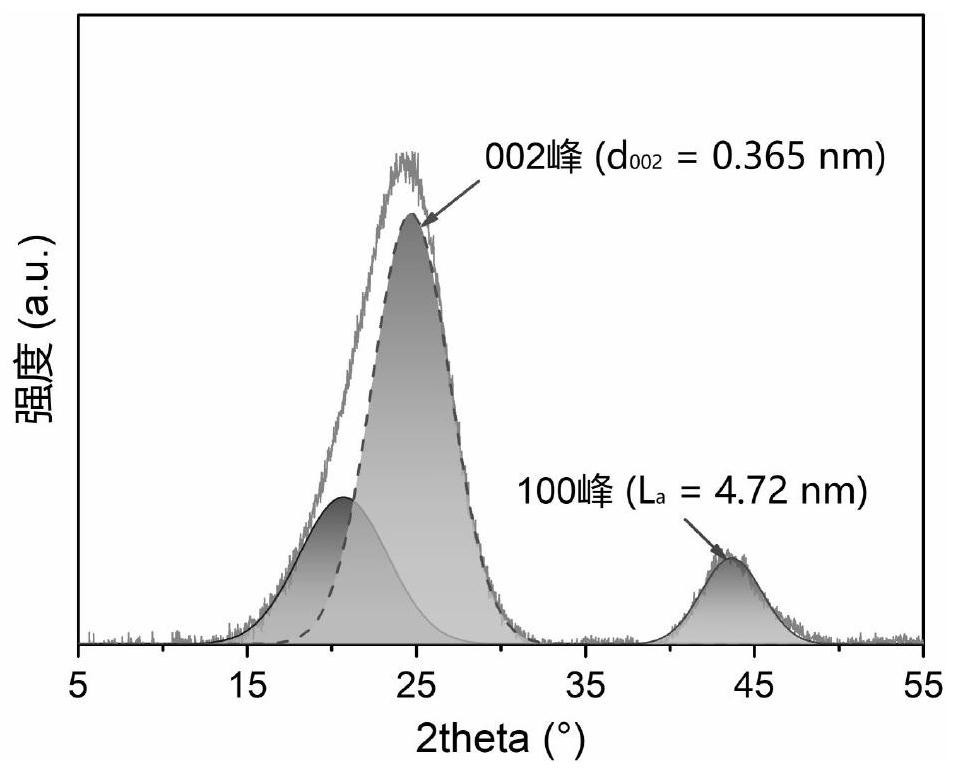

Preparation method of anthracite-based hard carbon material combining pre-activation pore-forming and high-temperature carbonization

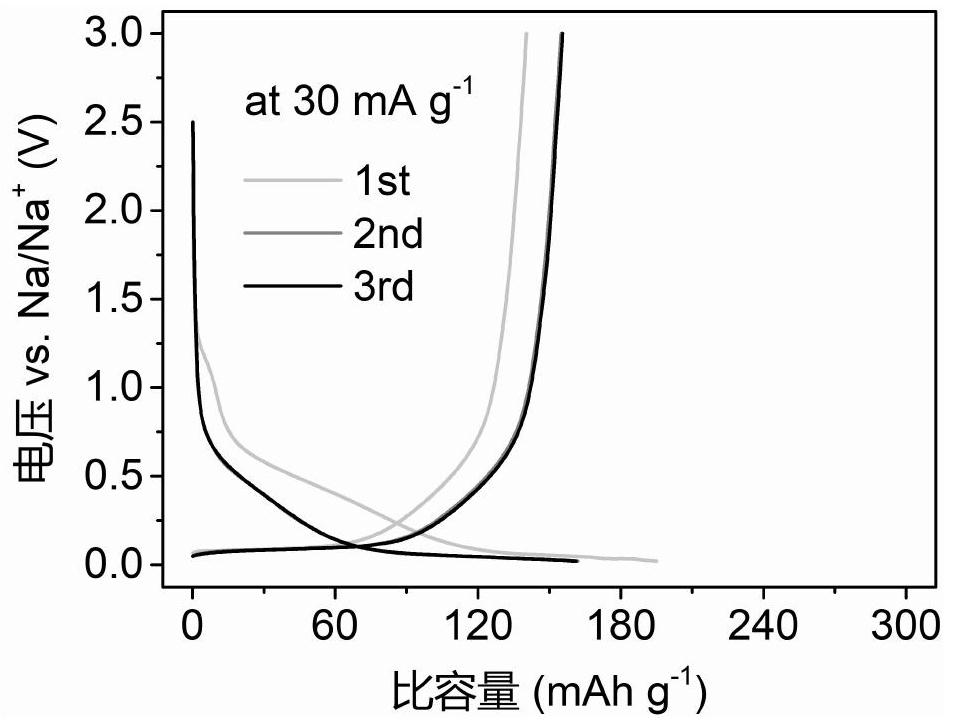

A high-temperature carbonization and pre-activation technology, which is applied in the preparation/purification of carbon, active material electrodes, electrochemical generators, etc., can solve the problem of continuity damage of porous carbon microchip layer, low first cycle coulombic efficiency, and failure to meet high Performance problems such as the preparation of anthracite-based hard carbon materials, to achieve the effect of improving low first Coulombic efficiency, high first Coulombic efficiency, and low reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Specific implementation mode 1: This implementation mode records a method for preparing anthracite-based hard carbon materials combined with preactivation pore formation and high-temperature carbonization. The steps of the method are:

[0034] Step 1: Grinding: Crushing and screening the raw coal to obtain powder with target particle size;

[0035] Step 2: Pre-activation: For physical activation, the activation gas is introduced under the inert gas, and the total flow rate should be controlled at 0.6-4.5L / (m 3 min), the flow ratio of the activated gas to the inert gas is 1:4-0, the temperature is raised to 700-1000°C at a heating rate of 2-20°C / min, and the temperature is kept for 1-6h to obtain a pre-activated product; for chemical activation, According to the mass ratio of activator to powder of 0.5-4:1, add activator for solid-phase premixing. Under the protection of inert atmosphere, raise the temperature to 700-1000°C at a heating rate of 2-20°C / min, and keep it wa...

specific Embodiment approach 2

[0038]Specific embodiment two: the preparation method of an anthracite-based hard carbon material combined with pre-activation pore-forming and high-temperature carbonization described in specific embodiment one. The actual effect of structural regulation, the raw coal is one or more of the No. 1 to No. 3 anthracite coals.

specific Embodiment approach 3

[0039] Embodiment 3: In Embodiment 1, a method for preparing anthracite-based hard carbon materials combined with pre-activation pore-forming and high-temperature carbonization, in step 1, in order to ensure the activation depth in the pre-activation step and facilitate the end of the carbonization step Afterwards, a carbon electrode is produced, and the target particle size is 80-400 mesh.

[0040] Embodiment 4: The method for preparing an anthracite-based hard carbon material combined with preactivation pore-forming and high-temperature carbonization described in Embodiment 1, in steps 2 and 3, the inert gas is one of nitrogen and argon or more.

[0041] Embodiment 5: The preparation method of anthracite-based hard carbon material combined with pre-activated pore-forming and high-temperature carbonization described in Embodiment 1, in step 2, the activation gas is water vapor, carbon dioxide, ammonia or oxygen One or more mixtures are used for etching to form sub-nano to na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com