A kind of ester group, cyano co-modified SBS thermoplastic dielectric elastomer material and preparation method thereof

A dielectric elastomer, co-modification technology, applied in the field of new SBS-based thermoplastic dielectric elastomer materials and its preparation, can solve the problems affecting the development of dielectric elastomer drivers, increased dielectric loss, and many defects in composite materials , to achieve the effect of improving the electric drive performance and increasing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

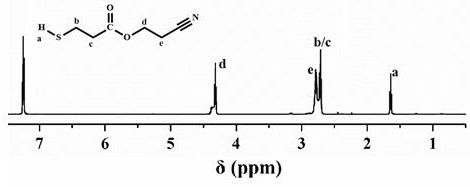

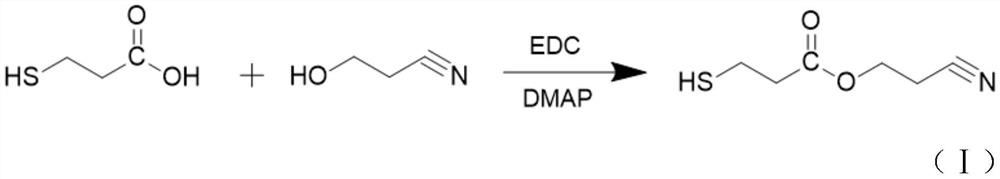

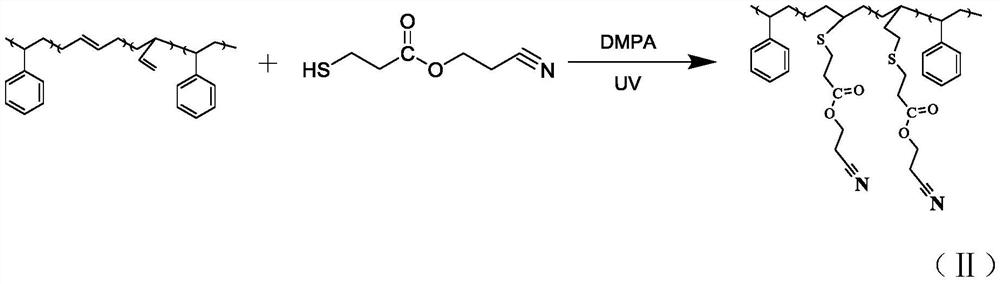

[0019] (1) The specific preparation steps are as follows: 10.6g of mercaptopropionic acid and 15g of cyanoethanol are added to the three-necked beaker, and 100mL of water agent toluene and 0.1 to 0.5g of catalyst p-toluenesulfonic acid are added to the bottle, Under the protection of argon, heating and refluxing at 100 °C for 12 h to separate water and purify to obtain ethyl mercaptopropionate;

[0020] (2) Dissolve 1 g of SBS in 50 mL of tetrahydrofuran, add 11 g of ethyl mercaptopropionate prepared in step (1) and 0.16 g of DMPA, and react under ultraviolet light for 30 min. After the reaction, the obtained solution was evaporated at 40°C using a vacuum rotary evaporator to remove part of the solvent and then precipitated in ethanol. After filtration, the precipitate was dissolved in tetrahydrofuran and then purified by ethanol precipitation. After repeating three times, the new SBS base was obtained by vacuum drying. Thermoplastic Dielectric Elastomer material. The results...

Embodiment 2

[0022] (1) Add 10.6 g of mercaptopropionic acid and 15 g of cyanoethanol into a three-necked beaker, and add 100 mL of toluene with water agent and 0.1 to 0.5 g of catalyst p-toluenesulfonic acid to the bottle, under argon protection Heating and refluxing at 100℃ for 12h and then purifying to obtain ethyl mercaptopropionate nitrile ethyl ester;

[0023] (2) Dissolve 1 g of SBS in 50 mL of tetrahydrofuran, add 11 g of ethyl mercaptopropionate prepared in step (1) and 0.25 g of DMPA, and react under ultraviolet light for 40 min. After the reaction, the obtained solution was evaporated at 40°C using a vacuum rotary evaporator to remove part of the solvent and then precipitated in ethanol. After filtration, the precipitate was dissolved in tetrahydrofuran and then purified by ethanol precipitation. After repeating three times, the new SBS base was obtained by vacuum drying. Thermoplastic Dielectric Elastomer material. The results show that the dielectric constant can reach 15 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com