System and method for calcining treatment and resource utilization of sugar-making filter mud

A technology of filtering mud for sugar production and calcination treatment, which is applied in the direction of combustion method, combustion product treatment, incinerator, etc., and can solve the problems of large manual workload, complicated operation, and inability to efficiently utilize resources, and achieve single type and work efficiency. The effect of low quantity, easy procurement and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

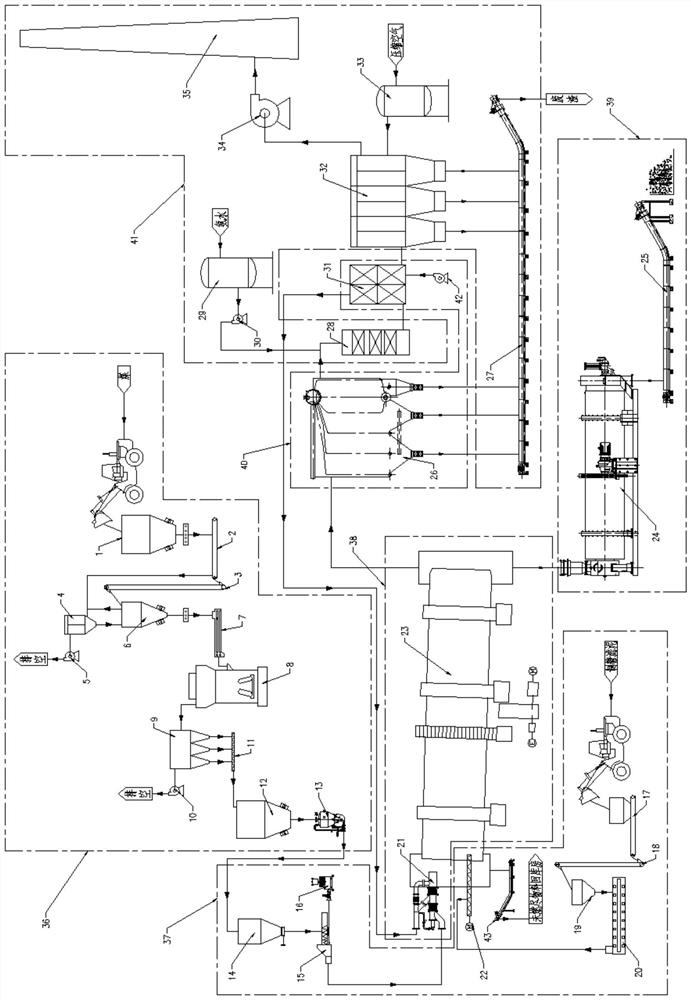

[0043] This embodiment discloses a system for calcination treatment and resource utilization of sugar filter mud, such as figure 1 As shown, it includes a pulverized coal preparation system 36, a feeding system 37, a calcination system 38, a waste heat recovery system 40, a flue gas environmental protection standard emission treatment system 41 and a quicklime recovery system 39;

[0044] The pulverized coal preparation system 36 includes a raw coal hopper 1, a raw coal belt conveyor 2, a raw coal hopper hoist 3, a bin top dust collector 4, a raw coal bunker 6, a coal feeder 7, a coal mill 8, and a coal mine that are connected in sequence. Powder collector 9, pulverized coal conveyor 11, pulverized coal bin 12 and bin pump conveyor 13. The roof dust collector 4 and the pulverized coal collector 9 are also connected with a roof dust collector fan 5 and a pulverizing fan 10 respectively;

[0045] The feeding system 37 includes a coal scuttle 14 and a pulverized coal screw conve...

Embodiment 2

[0053] This embodiment discloses a method for calcination treatment and resource utilization of sugar filter mud by using the above system, including the following contents:

[0054] (1) The raw coal is transported from the raw coal hopper 1 to the raw coal hopper elevator 3 through the raw coal belt conveyor 2, and then sent to the raw coal bunker 6 through the raw coal hopper elevator 3 for buffer storage, and then from the bottom of the raw coal bunker 6 The closed quantitative coal feeder 7 is sent to the vertical coal mill 8 for pulverization, and the pulverized coal is collected by a special pulse pulverized coal collector 9, and the pulverized coal collected is sent to the The pulverized coal is stored in the bin 12, transported to the coal hopper 14 through the bin pump conveyor 13, and then enters the pulverized coal burner 21 through the pulverized coal screw conveyor 15 for auxiliary combustion, providing the required heat for the rotary kiln calciner 23 .

[0055]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com