Method for preparing p-aminophenol from nitrobenzene

A technology of p-aminophenol and nitrobenzene, which is applied in the field of catalytic hydrogenation, can solve the problems of reducing the cost of catalysis, reducing poisoning, and difficulty in handling sulfuric acid, and achieves the effects of simple preparation process, accelerated reaction rate, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

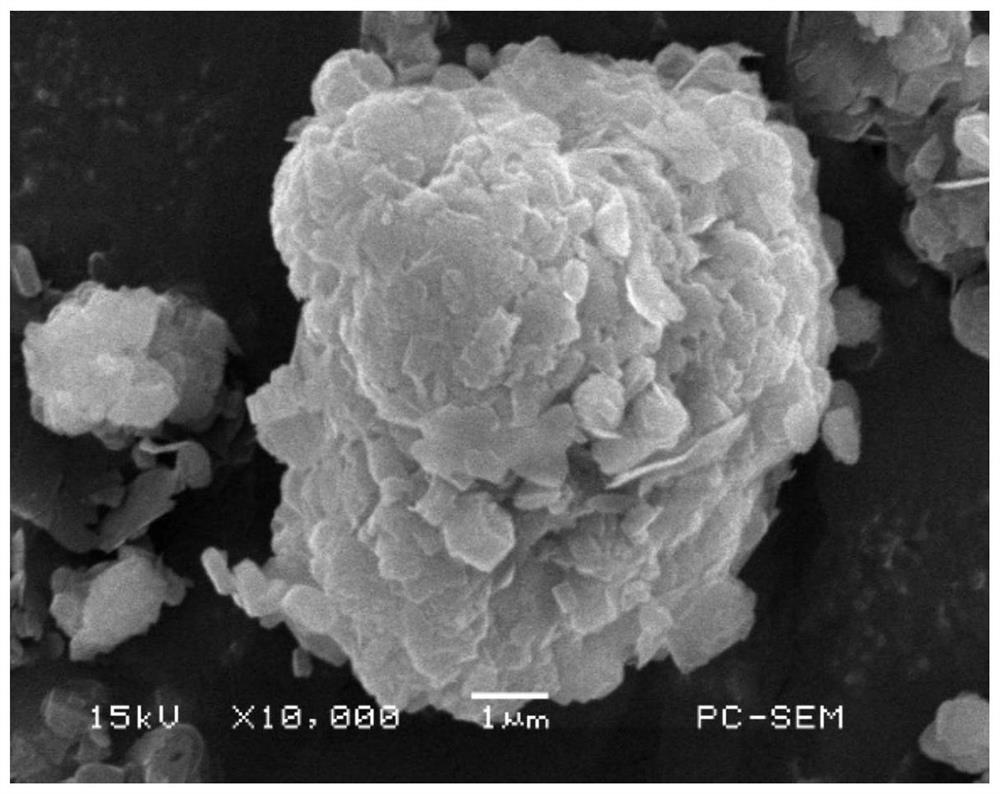

Embodiment 1

[0023] In the first step, weigh 1 g of HZSM-5 molecular sieve and put it into a muffle furnace, and bake it at 500°C for 6 hours. Then soak in dilute sulfuric acid (0.5 mol / ml, mass ratio to carrier: 1:10, the same below) for 1 hour, dry it and put it into a muffle furnace for calcination at 400°C for 5 hours.

[0024] The second step, weigh 0.1397gH 2 PtCl 6 ·6H 2 O (equivalent to metal Pt is 0.05263g), dissolved in water to prepare an impregnating solution, using the equal volume impregnation method to use 1g of the HZSM-5 molecular sieve treated in step 1 as a carrier and soaking in the impregnating solution for half an hour.

[0025] In the third step, put the material impregnated in the second step into an oven and dry at 100°C.

[0026] In the fourth step, the material obtained in the third step is put into a muffle furnace and fired at 500° C. for 3 hours.

[0027] In the fifth step, put the burned material in the fourth step into a tube furnace at 500° C. for hydro...

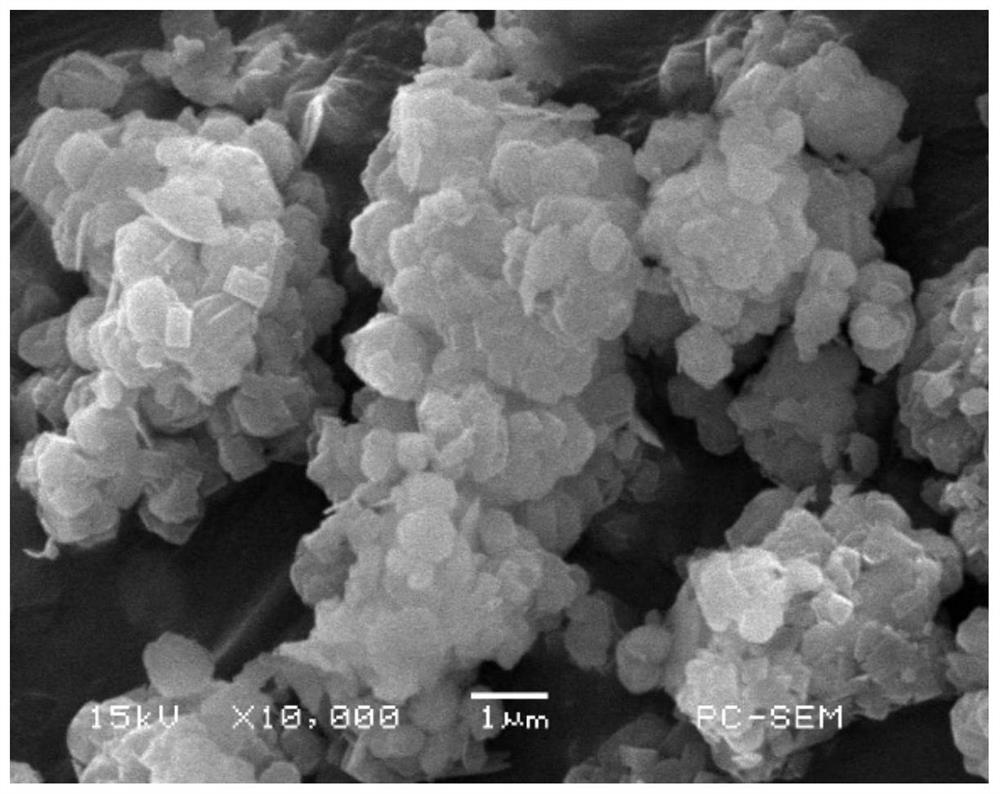

Embodiment 2

[0030] Step is with embodiment 1.

[0031] Carrier is HZSM-5 molecular sieve (silicon to aluminum ratio 45) in this catalyst, and the loading capacity of metal Pt is 5%

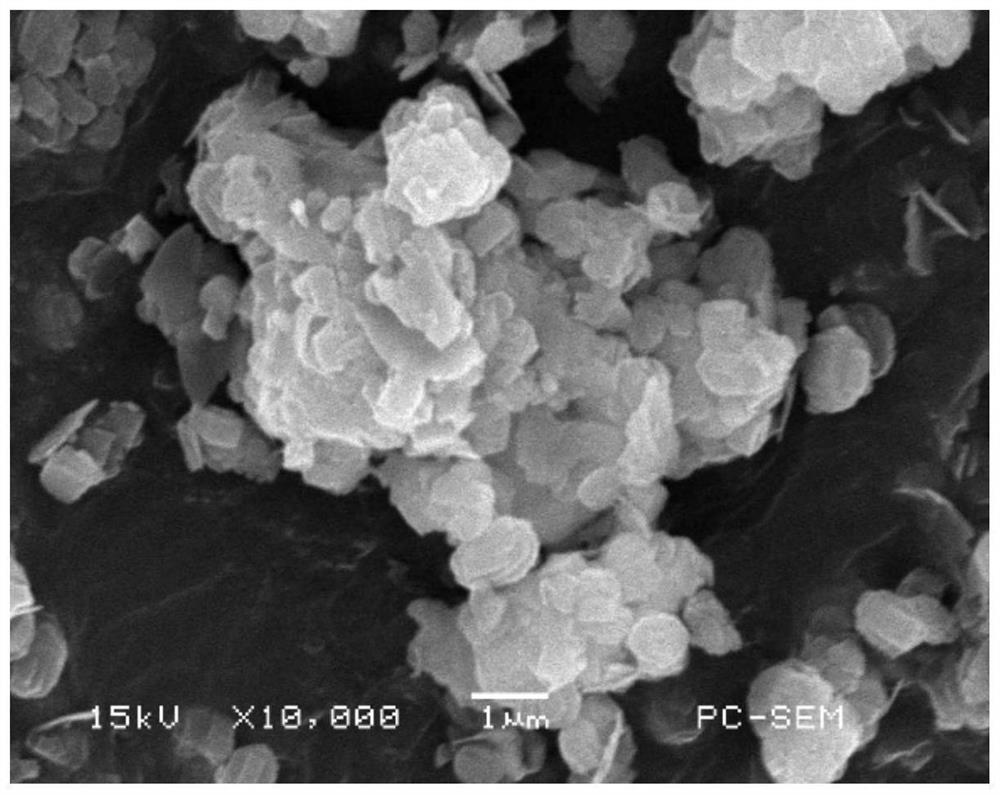

Embodiment 3

[0033] In the first step, weigh 1 g of HZSM-5 molecular sieve and put it into a muffle furnace, and bake it at 700°C for 4 hours. After soaking in dilute sulfuric acid for 1 hour, put it into a muffle furnace and bake at 300°C for 6 hours.

[0034] The second step, weigh 0.1106gH 2 PtCl 6 ·6H 2 O (equivalent to metal Pt is 0.04167g), dissolved in water to prepare an impregnating solution, and 1 g of HZSM-5 molecular sieve as a carrier was placed in the impregnating solution for half an hour by equal volume impregnation method.

[0035] In the third step, put the material impregnated in the second step into an oven and dry at 100°C.

[0036] In the fourth step, put the material obtained in the third step into a muffle furnace and burn it at 600° C. for 2 hours.

[0037] In the fifth step, put the burnt material in the fourth step into a tube furnace at 600° C. for hydrogen reduction for 3 hours to obtain a catalyst for preparing p-aminophenol from nitrobenzene.

[0038] Carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com