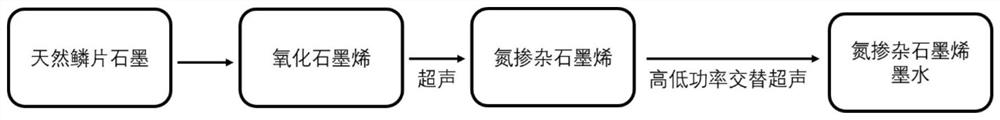

Method for preparing nitrogen-doped graphene ink with assistance of sodium deoxycholate

A nitrogen-doped graphene and graphene ink technology, applied in the field of 3D printing materials, can solve the problems of small lamella size, unfavorable increase in lamella overlap rate, unfavorable lamella overlap rate, etc., and achieve stable dispersion. , Significant cost-effectiveness and environmental protection, good lap joint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Graphene Oxide Preparation

[0035] (1) Add graphite powder into concentrated sulfuric acid, the concentration of graphite powder is 0.04g / mL, after fully mixing, mix according to the mass ratio of graphite and potassium permanganate ratio of 1:6, after gradient heating reaction, cool to room temperature , to obtain a mixture.

[0036] (2) Wash the mixture with deionized water until neutral, and pour off the supernatant. Complete this process with a centrifuge.

[0037] (3) Collect the bottom layer slurry, freeze-dry after ultrasonic treatment, and obtain graphene oxide powder.

[0038] In the above graphene oxide preparation method, in the above (1), the temperature gradient is set to 3, the temperature gradients are 5, 35, and 70°C in sequence, and the reaction time is 0.5, 1, and 0.5h in sequence.

[0039] And / or, in the above (2), the centrifugation speed is 8000rpm, and the time is 20min.

[0040] In (3), the duration of ultrasound is 0.5h, and the powe...

Embodiment 2

[0055] Step 1: Preparation of Graphene Oxide Powder Using Natural Flake Graphite Powder

[0056] (1) Add graphite powder into concentrated sulfuric acid, the concentration of graphite powder is 0.04g / mL, after fully mixing, mix according to the mass ratio of graphite and potassium permanganate ratio of 1:6, after gradient heating reaction, cool to room temperature , to obtain a mixture.

[0057] (2) Wash the mixture with deionized water until neutral, and pour off the supernatant. Complete this process with a centrifuge.

[0058] (3) Collect the bottom layer slurry, freeze-dry after ultrasonic treatment, and obtain graphene oxide powder.

[0059] In the above graphene oxide preparation method, in (1), five temperature gradients are set, the temperature gradients are 5, 15, 35, 45, and 70°C in sequence, and the reaction time is 0.5, 1, 1, 0.5, and 1h in sequence.

[0060] And / or, in the above (2), the centrifugation speed is 6000rpm, and the time is 15min.

[0061] In (3), ...

Embodiment 3

[0076] Step 1: Preparation of Graphene Oxide Powder Using Natural Flake Graphite Powder

[0077] (1) Add graphite powder into concentrated sulfuric acid, the concentration of graphite powder is 0.04g / mL, after fully mixing, mix according to the mass ratio of graphite and potassium permanganate ratio of 1:6, after gradient heating reaction, cool to room temperature , to obtain a mixture.

[0078] (2) Wash the mixture with deionized water until neutral, and pour off the supernatant. Complete this process with a centrifuge.

[0079] (3) Collect the bottom layer slurry, freeze-dry after ultrasonic treatment, and obtain graphene oxide powder.

[0080] In the above-mentioned graphene oxide preparation method, in the above (1), two temperature gradients are set, the temperature gradients are 2 and 65°C in sequence, and the reaction time is 2 and 8h in sequence.

[0081] And / or, in the above (2), the centrifugation speed is 10 000 rpm, and the time is 15 min.

[0082] In (3), the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com