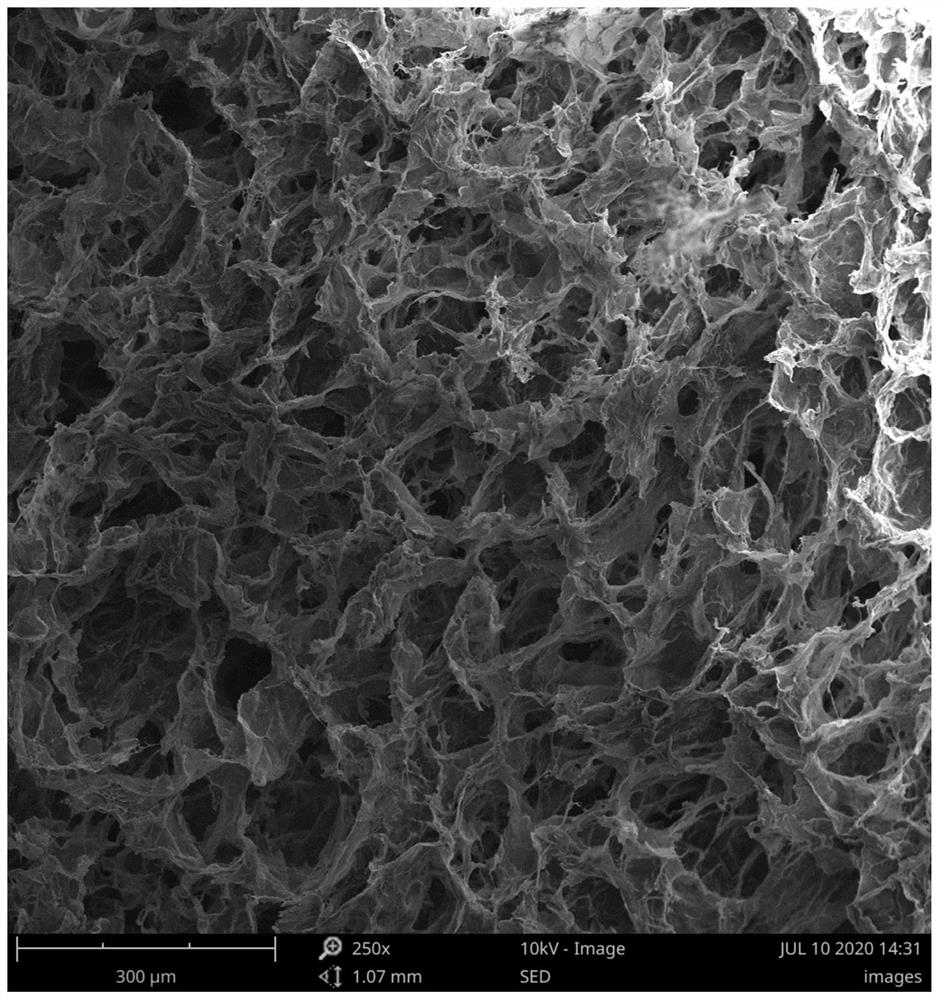

Stress sensing conductive aerogel and preparation method thereof

A stress sensing and aerogel technology, applied in the field of aerogels, can solve the problems of poor strength, fragility, and volume shrinkage of nanocellulose aerogels, and achieve increased conductive networks, environmentally friendly materials, and conductive The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

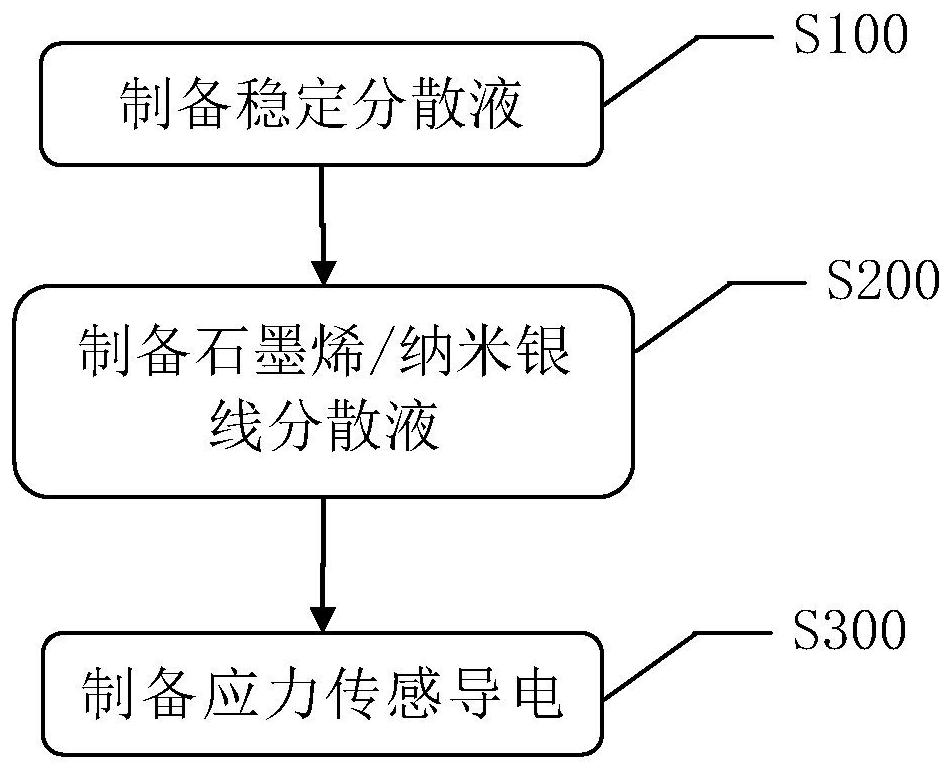

[0027] like figure 2 As shown, the preparation method of the stress-sensing conductive airgel of the present invention comprises the following steps:

[0028] Step 100. Preparing a stable dispersion liquid——slowly adding graphene oxide into the ethanol solution, and performing ultrasonic dispersion; wherein, the ultrasonic dispersion is specifically ultrasonic dispersion at 80-100w ultrasonic power for 5-10 minutes.

[0029] Step 200. Prepare the graphene / silver nanowire dispersion——add the stable dispersion in step 100 to the ethylene glycol solution for preheating, and then add FeCl 3 and ethylene glycol solution, continue to heat, then add dropwise the AgNO 3 Mix the ethylene glycol mixed solution prepared by mixing with PVP evenly, and stir the reaction at a constant temperature, then cool to room temperature, wash the product with ethanol and deionized water, and finally re-disperse the product ultrasonically with deionized water to obtain graphite ene / nanosilver wire ...

Embodiment

[0034] The preparation process of the stress-sensing conductive airgel described in this example is as follows:

[0035] 1. Prepare a stable dispersion: graphene oxide is slowly added to the ethanol solution, and ultrasonically dispersed for 5 minutes under 100w ultrasonic power to form a stable dispersion (graphene oxide ethanol dispersion), and the concentration of the graphene oxide ethanol dispersion is 4mg / mL;

[0036] 2. Preparation of graphene / nanometer silver wire dispersion: Add the graphene oxide ethanol dispersion in step 1 into the ethylene glycol solution and pre-heat to 150°C-200°C for 1h, then add 0.6mmol / L FeCl 3 and ethylene glycol solution 2.5mL, continue heating for 10min; then AgNO 3 and PVP according to the molar ratio of 1:2 to prepare an ethylene glycol mixed solution, and after mixing evenly, add the above system dropwise at a certain speed (that is, add FeCl 3 And ethylene glycol solution and continue to heat the solution), ensure that the dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com