Aluminothermic welding post-weld heat treatment process for bainite steel rail

A technology of post-weld heat treatment and post-heat treatment, which is applied in the field of rail welding and can solve problems such as easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

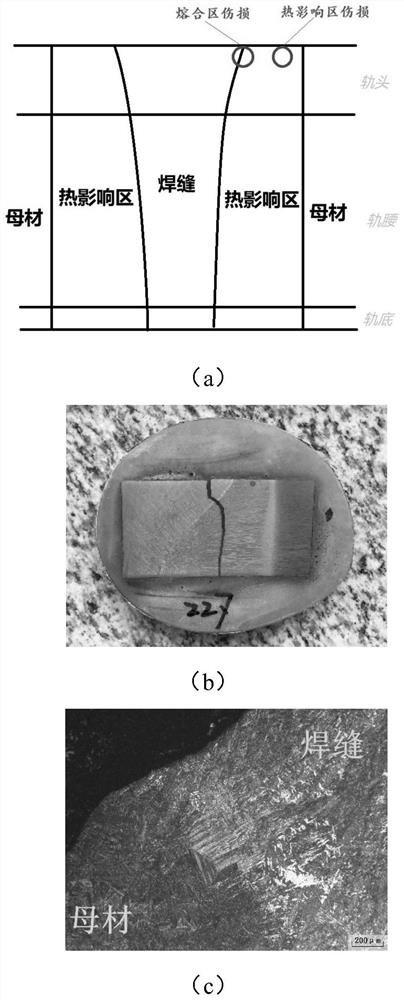

Problems solved by technology

Method used

Image

Examples

Embodiment 1

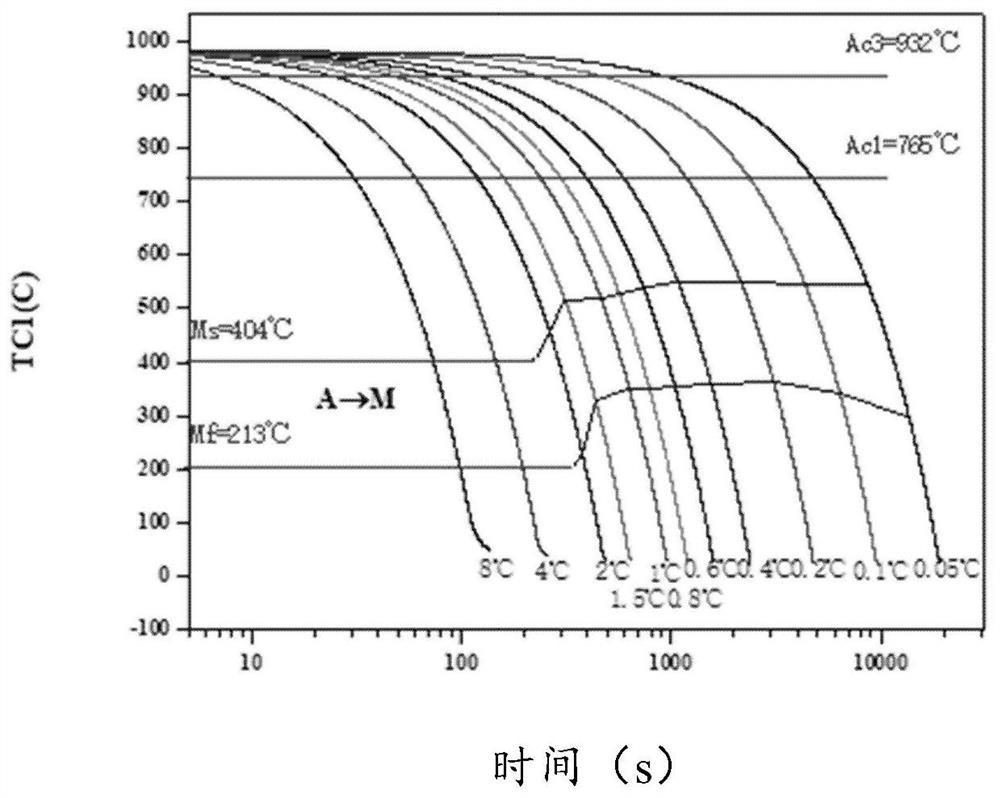

[0054] Gleeble-1500D thermal simulation testing machine is used to determine the transformation temperature of the steel by using the expansion or contraction of the volume of the steel during the phase transition. The round bar sample is taken from the welded joint, and the sample is heated by the thermal simulator to a constant temperature. Rapid cooling, measure the temperature-expansion curve of the sample, use the tangent method to determine the characteristic phase transition temperature point, and use the computer to draw the "temperature-time (logarithmic)" curve to obtain the CCT curve. Among them, the joint obtained by thermite welding is cooled to room temperature, and then the joint sample is heated by the built-in equipment of the thermal simulator. The heating temperature is 980 ° C, the heating time is 5 minutes, and the heat preservation is 10 minutes; The transformation curve obtained after cooling is as image 3 shown.

[0055] The microstructure of the join...

Embodiment 2

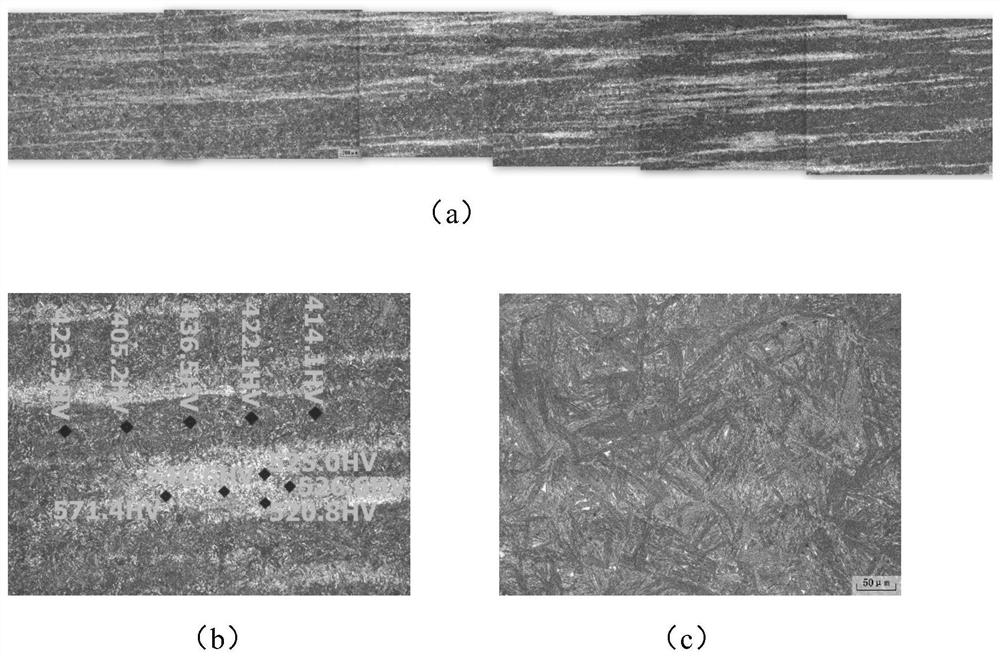

[0057] At room temperature, the microstructure of the samples obtained in Example 1 at different cooling rates was observed with a DM15000M metallographic microscope. Samples were taken from samples obtained at different cooling rates, and the microstructure of each sample was observed after pre-grinding, polishing and erosion treatment. The FM-7 automatic microhardness tester was used to test each sample. After observing the microstructure, the microhardness was tested by indentation method with a load of 0.2kg, and the indentation size was measured to determine the microhardness. The results are shown in Table 2.

[0058] Table 2 Microstructure analysis results and hardness test results of joint samples obtained at different cooling rates

[0059]

[0060]

[0061] It can be seen from Table 2 that under the conditions of 8°C / s and 4°C / s, the structure of the welded joint is martensite, and the microhardness is above 500HV; under the condition of 2 to 1°C / s, the struct...

Embodiment 3

[0063] 1. Cool the joint obtained by thermite welding to room temperature, then heat the joint to 900-1000°C, and keep it warm for 10 minutes; then use a cooling rate of 0.2-0.8°C / s to slowly cool the joint obtained through heat preservation treatment , until the temperature of the joint reaches below 100°C, and then the tread hardness test is carried out.

[0064] With reference to TB / T 1632.3-2019, the tread hardness test is carried out on the welded joint at room temperature, sawing the welded joint longitudinally along the rail, grinding and polishing the top surface of the rail, and testing the weld hardness at the transverse position of the weld center on the top surface of the rail, testing 3 Point Brinell hardness, the calculated average hardness value is recorded as the tread hardness of the weld, and the test method of Brinell hardness is carried out in accordance with the provisions of GB / T 231.1-2009.

[0065] The results are shown in Table 3, where "no heat treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Tread hardness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com