Zinc stearate dispersion liquid and preparation method thereof

A technology of zinc stearate and dispersion liquid, used in papermaking, coating, pigment-containing coating and other directions, can solve the problems of incomplete reaction, easy precipitation, and difficult dispersion of products, and achieves low energy consumption and raw material cost, and reduced cost. Small coefficient of kinetic friction, the effect of improving coating gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

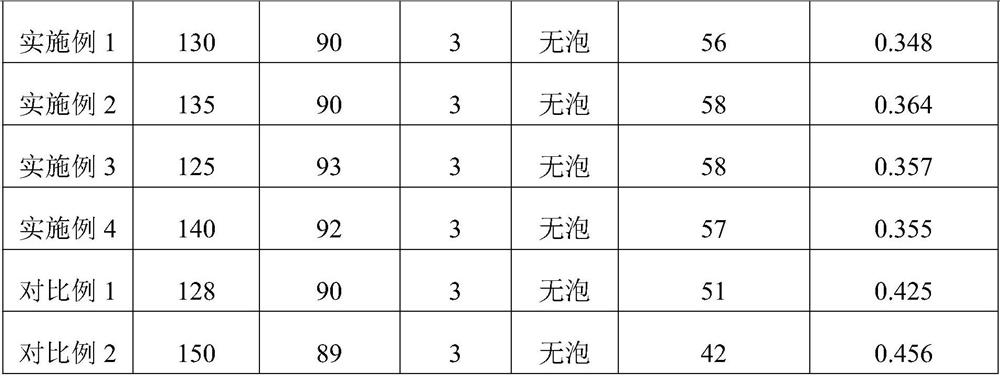

Embodiment 1

[0023] According to the formula ratio of zinc stearate emulsion, take 50 parts of water, 140 parts of stearic acid, 30 parts of zinc oxide, 0.5 parts of acetic acid, 1 part of chlorinated paraffin-42, and 1 part of defoamer into the reaction kettle (1) , the temperature was raised to 80°C, and the reaction was carried out for 1h. Add 50 parts of water, sodium fatty acid methyl ester sulfonate, 2 parts of nonylphenol polyoxyethylene ether, 3 parts of sorbitan monostearate, and 2 parts of sodium polyacrylate into the reaction kettle (2) , stir evenly and heat up to 80°C, add 0.5 parts of modified polysiloxane to defoam, add the emulsified dispersion obtained in the reactor (2) to the reactor (1) at one time, and shear at high speed for 1 hour (shear rate 2000r / min) through a homogenizer to quickly cool to below 30 degrees, discharge, add 15 parts of polyvinyl alcohol 400, adjust the solid content to 60%, and stir evenly to obtain the target product.

Embodiment 2

[0025] According to the formula ratio of zinc stearate emulsion, take 80 parts of water, 150 parts of stearic acid, 30 parts of zinc oxide, 0.5 part of oxalic acid, 0.1 part of chlorinated paraffin-70, and 1 part of defoamer into the reaction kettle (1) , the temperature was raised to 80°C, and the reaction was carried out for 1h. Add 50 parts of water, sodium fatty acid methyl ester sulfonate, 4 parts of nonylphenol polyoxyethylene ether equal proportion mixture, 5 parts of polyoxyethylene sorbitan monostearate, and 2 parts of sodium polyacrylate into the reaction kettle ( 2), stir evenly and heat up to 80°C, add 0.5 parts of modified polysiloxane to defoam, add the emulsified dispersion obtained in the reaction kettle (2) to the reaction kettle (1) at one time, and shear at high speed for 1 hour ( Shear rate 3000r / min), through a homogenizer (25MPa) to quickly cool to below 30 degrees, discharge, add 20 parts of polyacrylamide (molecular weight 2 million), adjust the solid c...

Embodiment 3

[0027] According to the formula ratio of zinc stearate emulsion, get 60 parts of water, 140 parts of stearic acid, 30 parts of zinc oxide, 0.5 part of citric acid, 0.5 part of chlorinated paraffin-52, and 1 part of defoamer to join in the reactor (1 ), heat up to 80°C, and react for 1h. Add 50 parts of water, sodium fatty acid methyl ester sulfonate, 3 parts of nonylphenol polyoxyethylene ether, 5 parts of polyoxyethylene sorbitan monostearate, and 2 parts of sodium tripolyphosphate into the reactor In (2), the emulsified dispersion obtained in the reaction kettle (2) is added to the reaction kettle (1) at one time, sheared at high speed for 1 hour (shear rate 3000r / min), and quickly cooled to Below 30 degrees, discharge, add 20 parts of glycerin, adjust the solid content to 60%, stir evenly, and obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com