Proton-type and alkali-metal-ion-type polyacid hybrid polymer with polymerization degree of 100 and preparation method thereof

An alkali metal ion and polymer technology, which is applied to the proton type and alkali metal ion type polyacid hybrid polymer with a degree of polymerization of 100 and the field of preparation thereof, and can solve the problems of limited application, ineffective ionization, insolubility, etc. , to achieve the effect of simple experimental processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

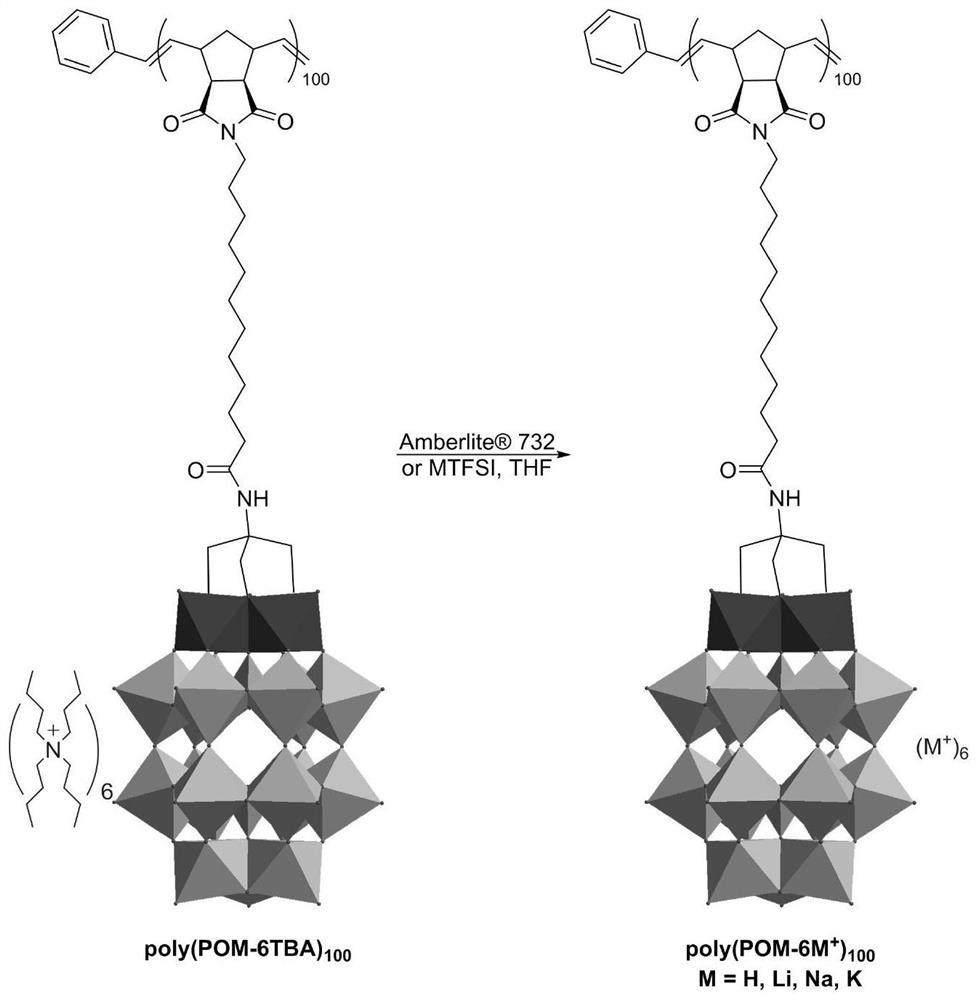

[0042] Example 1: The proton-type multi-acid hybrid polyelectrolyte poly(POM-6H with a degree of polymerization of 100 + ) 100 (Theoretical molecular weight is 438.4kDa) preparation

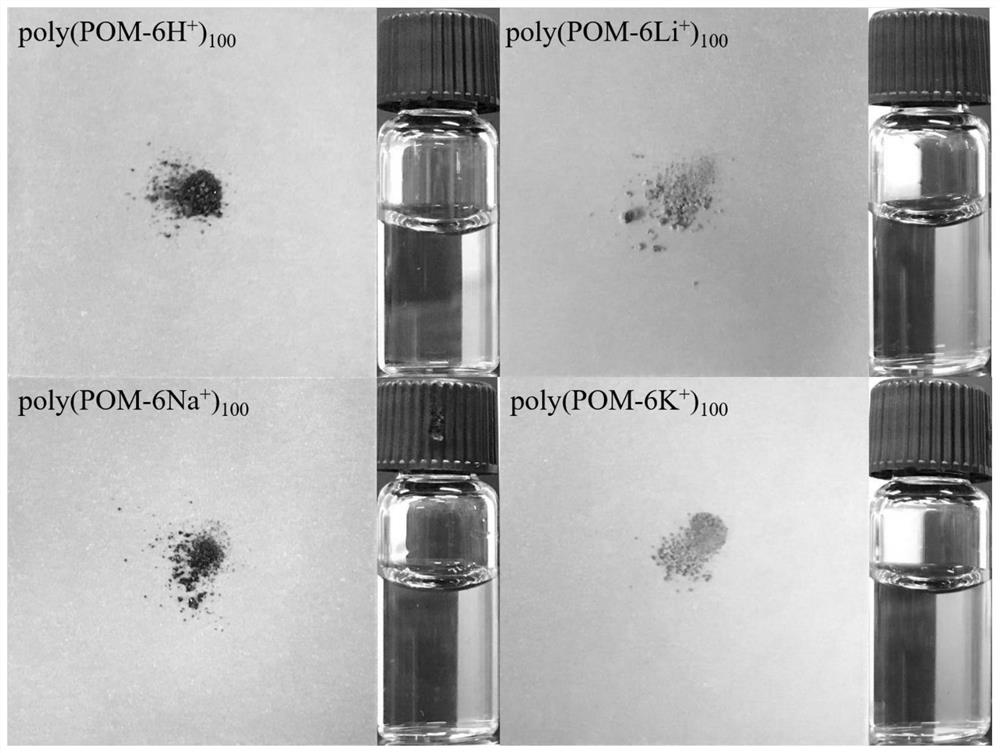

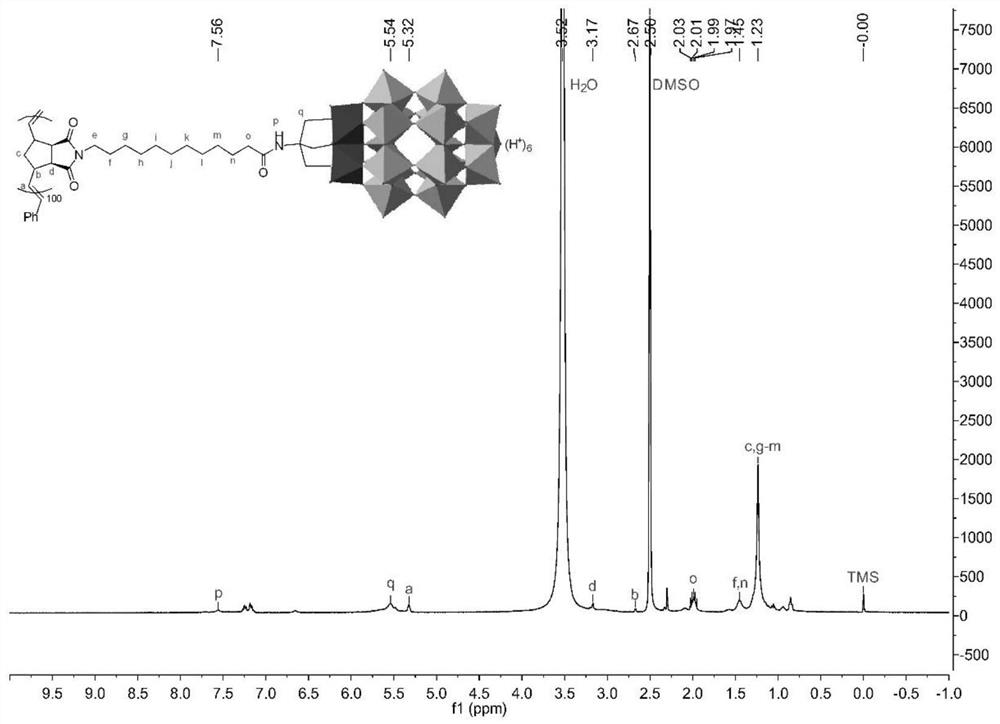

[0043] Take 25 mL of the treated cation exchange resin and pack it into the chromatographic column and add deionized water to wet it, and dissolve 50 mg of polyacid polymer poly(POM-6TBA) with a degree of polymerization of 100 and tetrabutylammonium ion as a counter ion with 1 mL of acetonitrile. ) 100 (theoretical molecular weight is 583.3kDa), the acetonitrile solution is dropped into the ion exchange column by wet loading. Rinse the resin column with water as the mobile phase, receive a clear and transparent yellow aqueous solution below, remove the mobile phase by vacuum evaporation, and obtain brown-yellow powder poly(POM-6H + ) 100 Such as figure 2 As shown, the yield was 33 mg, and the yield was 88%. product of 1 H NMR spectrum as image 3 as shown, 31 P NMR spectrum as Figure ...

Embodiment 2

[0044] Example 2: The lithium-ion type polyacid hybrid polyelectrolyte poly(POM-6Li with a degree of polymerization of 100 + ) 100 (Theoretical molecular weight is 442.0kDa) preparation

[0045] To 50mg of polyacid polymer poly(POM-6TBA) 100 Add 0.7mL of LiTFSI in THF solution (1mol / L) to form a suspension system, and ion exchange occurs after vigorous stirring. The ion-exchange solution was replaced every 8 hours, and the precipitate was washed with MeCN and THF after repeated 5 times, and the dark green powder poly(POM-6Li + ) 100 Such as figure 2 As shown, the yield was 33 mg, and the yield was 88%. product of 1 H NMR spectrum as Figure 5 as shown, 31 P NMR spectrum as Figure 6 shown; the concentration of 0.1mmol / L poly(POM-6Li + ) 100 Li at 0.1mol / L 2 SO 4 In the supporting electrolyte solution, the CV curves at different scanning speeds are as follows Figure 16 shown.

Embodiment 3

[0046] Embodiment 3: the sodium ion type multi-acid hybrid polyelectrolyte poly(POM-6Na + ) 100 (Theoretical molecular weight is 451.6kDa) preparation

[0047] To 50mg of polyacid polymer poly(POM-6TBA) 100 Add 0.7mL of NaTFSI in THF solution (1mol / L) to form a suspension system, and ion exchange occurs after vigorous stirring. The ion-exchange solution was replaced every 8 hours, and after repeated 5 times, the precipitate was washed with MeCN and THF, and vacuum-dried to obtain poly(POM-6Na + ) 100 Such as figure 2 As shown, the yield was 34 mg, and the yield was 89%. product of 1 H NMR spectrum as Figure 7 as shown, 31 P NMR spectrum as Figure 8 shown; the concentration of 0.1mmol / L poly(POM-6Na + ) 100 Na at 0.1mol / L 2 SO 4 In the supporting electrolyte solution, the CV curves at different scanning speeds are as follows Figure 17 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com