A kind of preparation method of anti-overcharge lithium-ion battery pole piece

A lithium-ion battery, anti-overcharge technology, applied in the direction of battery electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of reduced battery cycle life, battery temperature rise, battery combustion, etc., to achieve increased internal resistance, Prevent powdering and reduce side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

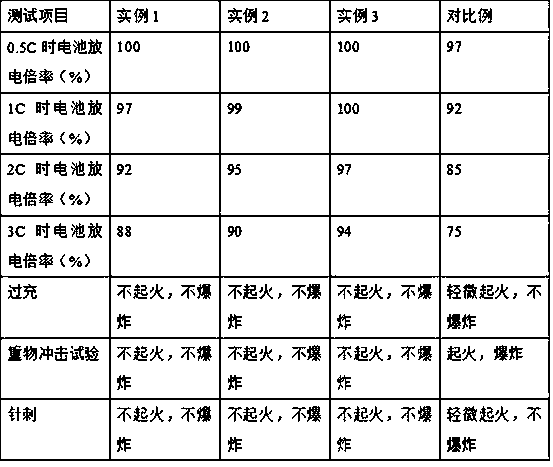

Examples

example 1

[0023] Weigh 24g of sodium alginate, grind and pulverize it for 8 minutes, pass through a 100-mesh sieve, collect the sieved sodium alginate powder, then weigh 5g of sodium lauryl sulfate, pour it into a beaker with 36mL of deionized water, and place it in ultrasonic dispersion Ultrasonic dispersion in the instrument for 16 minutes to obtain a self-made dispersion, continue to mix and stir the sieved sodium alginate powder and the self-made dispersion at a mass ratio of 1:4 to obtain a modified sodium alginate dispersion; weigh 12g of nano-alumina and Mix and grind 16g of nano-silica for 6 minutes to obtain a mixed powder, then mix the mixed powder, modified sodium alginate dispersion and deionized water in a beaker at a mass ratio of 5:1:7, and continue stirring for 1 hour to obtain a self-made coating Slurry: Weigh 45g of polyethylene and heat it up to 90°C to soften it, add 6mL of 2-bromoanisole and 2mL of N-methylpyrrolidone to the softened polyethylene, mix and stir for 24...

example 2

[0025]Weigh 28g of sodium alginate, grind and pulverize it for 9 minutes, pass through a 100-mesh sieve, collect the sieved sodium alginate powder, then weigh 6g of sodium lauryl sulfate, pour it into a beaker with 38mL of deionized water, and place it in an ultrasonic dispersion Ultrasonic dispersion in the instrument for 18 minutes to obtain a self-made dispersion, continue to mix and stir the sieved sodium alginate powder and the self-made dispersion at a mass ratio of 1:4 to obtain a modified sodium alginate dispersion; weigh 14g of nano-alumina and Mix and grind 18g of nano-silica for 7 minutes to obtain a mixed powder, then mix the mixed powder, modified sodium alginate dispersion and deionized water in a beaker with a mass ratio of 5:1:7, and continue stirring for 1.5 hours to obtain a self-made coating layer slurry; weigh 50g of polyethylene and heat it up to 95°C to soften it, add 7mL of 2-bromoanisole and 3mL of N-methylpyrrolidone to the softened polyethylene, mix an...

example 3

[0027] Weigh 32g of sodium alginate and grind it for 10min, pass it through a 100-mesh sieve, collect the sieved sodium alginate powder, then weigh 7g of sodium lauryl sulfate and pour it into a beaker with 42mL of deionized water, and place it in ultrasonic dispersion Ultrasonic dispersion in the instrument for 20 minutes to obtain a self-made dispersion, continue to mix and stir the sieved sodium alginate powder and the self-made dispersion at a mass ratio of 1:4 for 20 minutes to obtain a modified sodium alginate dispersion; weigh 16g of nano-alumina and Mix and grind 20g of nano-silica for 8 minutes to obtain a mixed powder, then mix the mixed powder, modified sodium alginate dispersion and deionized water in a beaker at a mass ratio of 5:1:7, and continue stirring for 2 hours to obtain a self-made coating Slurry: Weigh 55g of polyethylene and heat it up to 100°C to soften it, add 8mL of 2-bromoanisole and 4mL of N-methylpyrrolidone to the softened polyethylene, mix and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com