Preparation method of high-purity lithium sulfide

A lithium sulfide, high-purity technology, applied in the direction of alkali metal sulfide/polysulfide, etc., can solve the problems of no index control and many impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

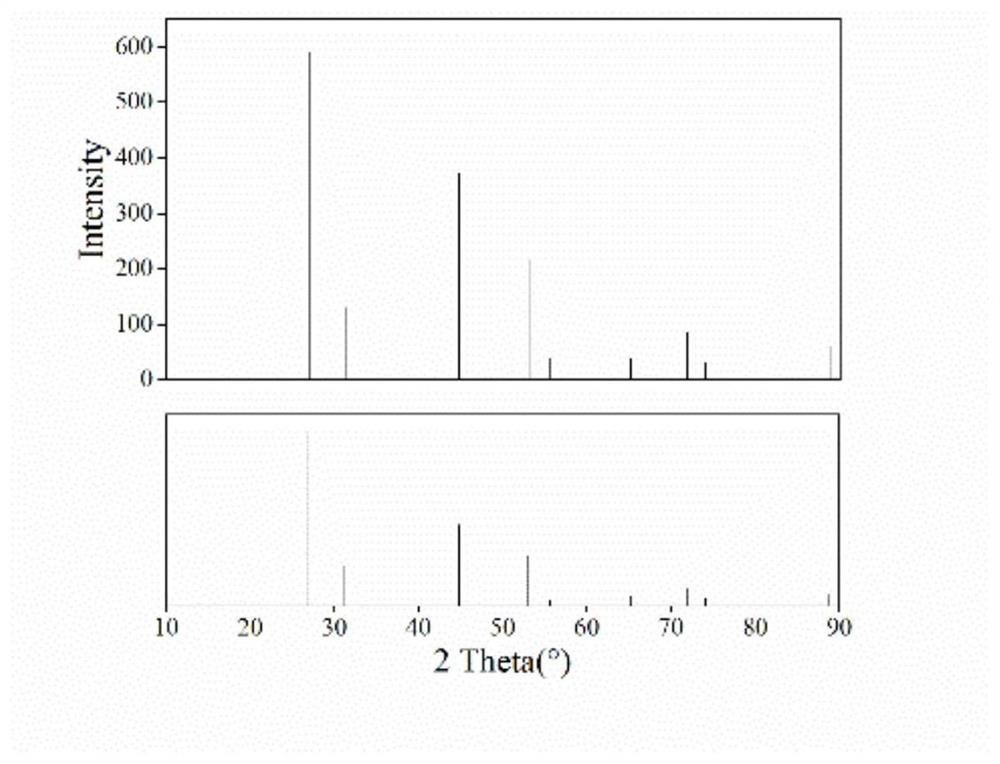

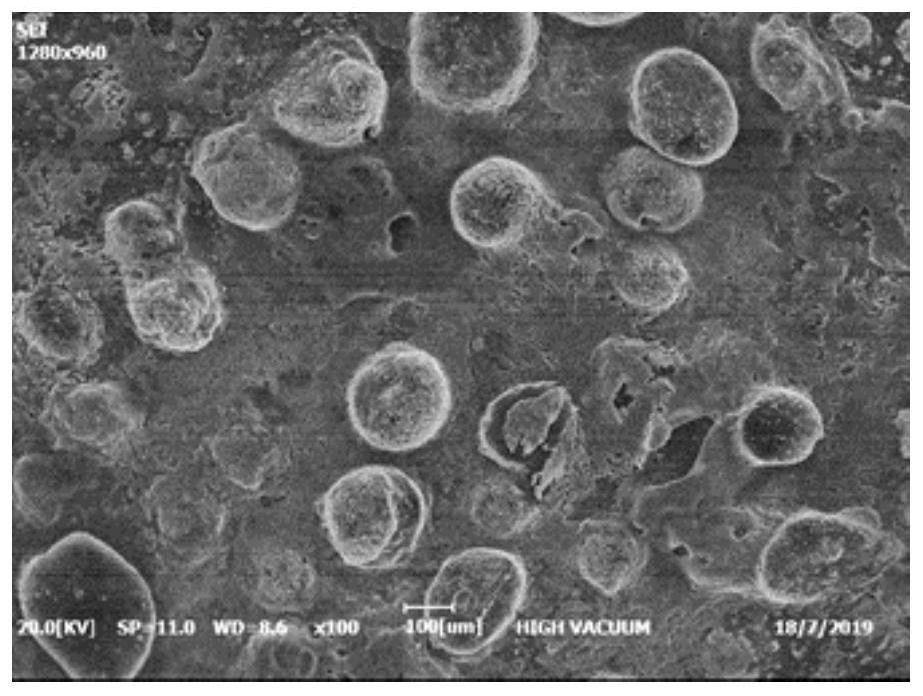

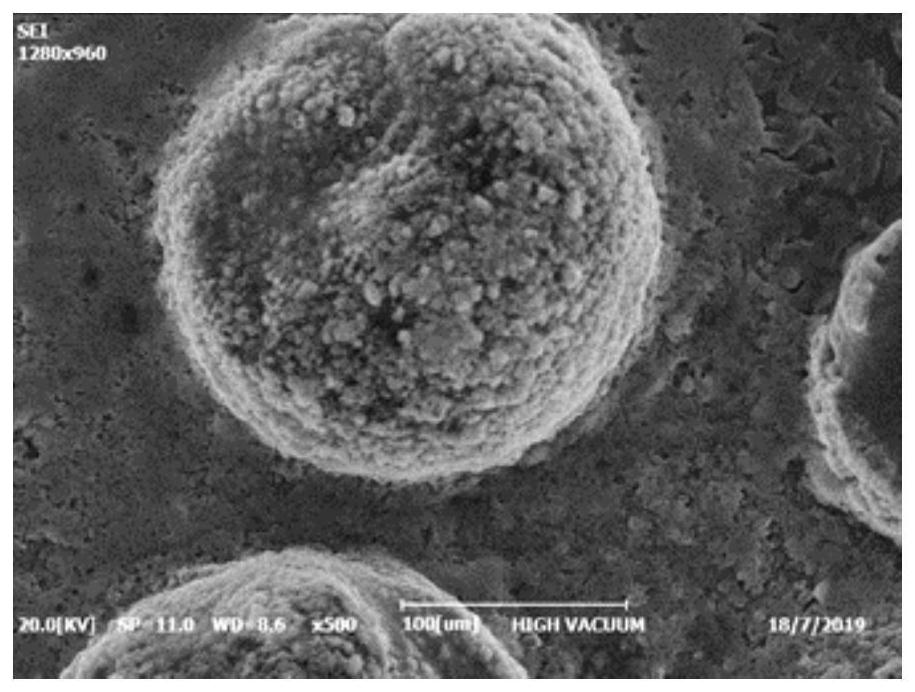

Image

Examples

preparation example Construction

[0026] The preparation method of high-purity lithium sulfide of the present invention, its steps are as follows successively:

[0027] a. Mixing materials: lithium sulfide precursor and sugar reducing agent according to Li 2 The molar ratio of O and C is mixed at 1:2.5~6 to obtain a mixed material; wherein, the lithium sulfide precursor is at least one of lithium sulfate, lithium sulfite, lithium bisulfate, and lithium dithionate;

[0028] b. Heating reaction: under the protection of vacuum or inert gas, react the mixed material at 200-300°C for 2-6h; then react at 400-600°C for 2-6h; then react at 675-775°C for 2-6h, cool to obtain reacted material;

[0029] c. Leaching, filtering and drying: add the reacted material to anhydrous alcohols, then filter, and the filtrate is dried to obtain high-purity lithium sulfide.

[0030] By adopting the method of the invention, high-purity lithium sulfide can be prepared, the purity of which is more than or equal to 99.9%, and the metho...

Embodiment 1

[0046] 1) Take 60g of AR grade anhydrous lithium sulfate and 49.1g of AR grade sucrose, mix and grind to 200-300 mesh;

[0047] 2) Melt-coat the uniformly ground material obtained in the previous step at 200°C for 4 hours under the protection of an inert gas or in a vacuum environment;

[0048] 3) Continue to carbonize and coat the molten coating material obtained in the previous step at 400°C for 6 hours under inert gas protection or vacuum environment;

[0049] 4) Continue to reduce and calcinate the carbonized coated material obtained in the previous step at 775°C for 2 hours under the protection of an inert gas or in a vacuum environment;

[0050] 5) After the material obtained in the previous step is cooled to normal temperature, it is dissolved in absolute ethanol at a mass solid-to-liquid ratio of 1:200, and then filtered, and the filtrate is kept for use, and the filter residue is washed with 5% hydrogen peroxide.

[0051] 6) The filtrate obtained in the previous step...

Embodiment 2

[0053] 1) Take 300g of AR grade lithium sulfite and 320g of AR grade glucose and mix and grind to 300-400 mesh;

[0054] 2) Melt-coat the uniformly ground material obtained in the previous step at 250°C for 3 hours under the protection of an inert gas or in a vacuum environment;

[0055] 3) Continue to carbonize and coat the molten coating material obtained in the previous step at 500°C for 3 hours under the protection of an inert gas or in a vacuum environment;

[0056] 4) Continue to reduce and calcinate the carbonized coated material obtained in the previous step at 750°C for 3 hours under the protection of inert gas or in a vacuum environment;

[0057] 5) After the material obtained in the previous step is cooled to normal temperature, it is dissolved in anhydrous methanol according to the mass solid-to-liquid ratio of 1:250, and then filtered, and the filtrate is kept for use, and the filter residue is washed with 10% hydrogen peroxide.

[0058] 6) The filtrate obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com