Regular strip-shaped grain boehmite and preparation method thereof

A technology of boehmite and crystal grains, which is applied in the field of hydrated alumina and its preparation, and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

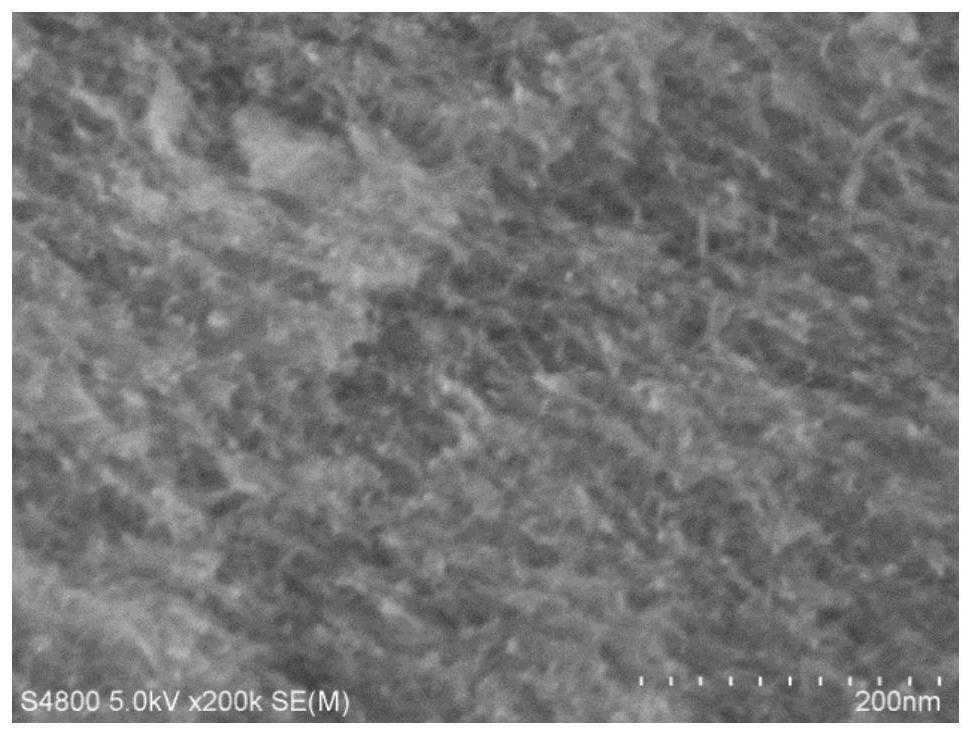

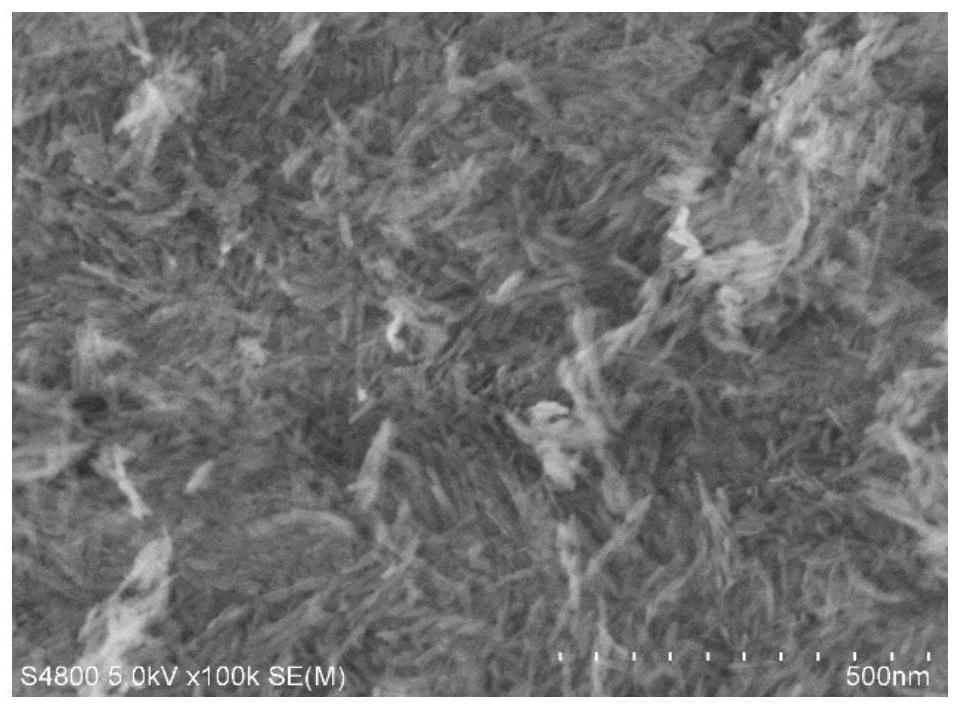

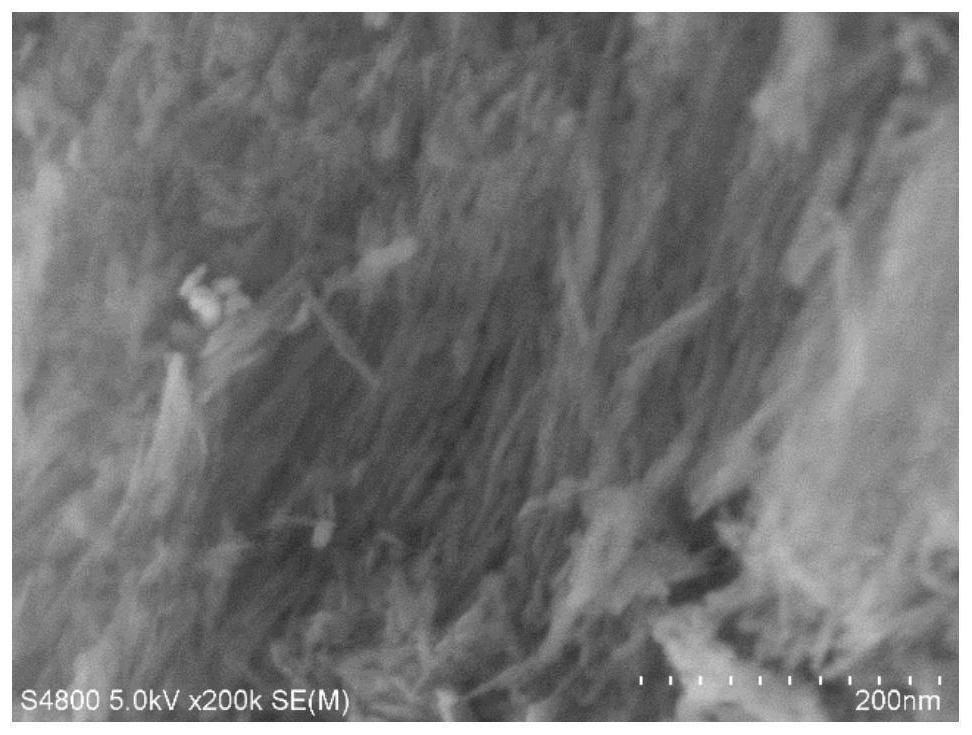

[0026] The preparation method of boehmite according to the present invention comprises adding a grain structure regulating agent into the aluminum hydroxide slurry obtained after the hydrolysis of alkoxy aluminum, aging for 0.5-72 hours under stirring at 60-260°C, and then drying, The structure regulating agent is hydroxycarboxylic acid and carboxylic acid, the mass ratio of hydroxycarboxylic acid to carboxylic acid is 0.1-2.0, and the molar ratio of hydroxycarboxylic acid to aluminum contained in the aluminum hydroxide slurry is 0.005-0.5.

[0027] In the above method, the hydrolysis temperature of the aluminum alkoxide is preferably 60-100°C, more preferably 75-95°C, the time is preferably 0.3-3 hours, more preferably 0.5-2 hours, the molar ratio of water to aluminum alkoxide Preferably it is 3.5-40, More preferably, it is 6-30. The hydrolysis of aluminum alkoxide is preferably carried out under stirring, and the stirring rate is preferably 100-300 rpm, preferably 120-250 rp...

example 1

[0050] In a three-necked flask with a reflux condenser, add 27 grams of aluminum beans with a purity of 99.9% by mass, and simultaneously add 90ml (0.7mol) of n-hexanol with a purity of 99.8% by mass, and start the reaction after reflux at 130°C for 20min, and continue to the three-necked flask. Slowly add 362 ml (2.9 mol) of n-hexanol into the flask, maintain the temperature at 140°C, and reflux for 2 hours to obtain a mixture of n-hexyl aluminum and n-hexanol.

[0051] Cool the mixture of n-hexyloxyaluminum and n-hexanol to 90°C, add 468g of deionized water to it under stirring at 120rpm for hydrolysis, the hydrolysis time is 45min, and the hydrolysis temperature is 90°C. Hydrolysis results in a two-phase system in which the upper layer is an alcohol phase and the lower layer is an aluminum hydroxide slurry phase. Decantation separates the water-containing ethanol phase of the upper strata, adds the grain structure regulating agent that is made up of 2-hydroxypropionic acid ...

example 2

[0054] Prepare boehmite by the method of example 1, difference is that used grain structure regulator is made up of 2-hydroxy propionic acid (lactic acid) of 9g and the acetic acid of 9g, adds the aluminum hydroxide slurry of grain structure regulator and is stirring The speed is 160rpm, and the temperature is aged at 120°C for 6 hours. After drying, boehmite B and its D (020) 、D (200) and D (002) , and D (200) / D (002) and D (002) / D (020) See Table 1, see Table 2 for acid dispersion index and water dispersion index. Boehmite B was calcined at 600°C for 6 hours in air to obtain γ-Al 2 o 3 Carrier b, its specific surface area and pore volume are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com