High-strength wear-resistant polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of polypropylene materials, can solve the problems of inconvenient practical application and poor wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

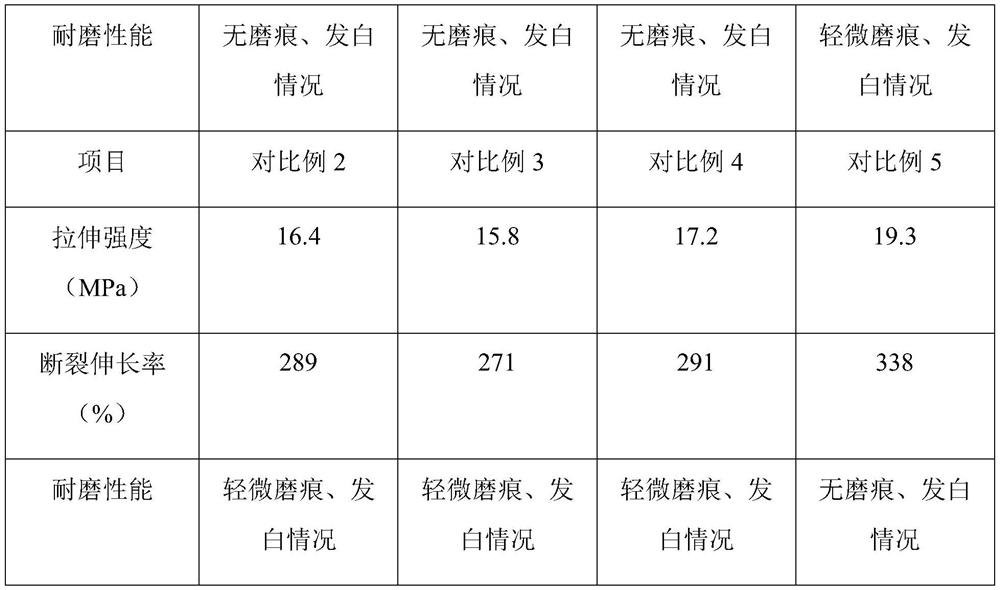

Examples

Embodiment 1

[0045] A method for preparing a high-strength wear-resistant polypropylene composite material, comprising the following steps:

[0046] (1) Prepare materials;

[0047] (2) Mix carbon powder and silicon dioxide, add ethanol solution to dissolve, ultrasonically disperse for 1 hour, vacuum dry at 70°C, vacuum sinter under argon atmosphere, sintering temperature is 1400°C, sintering time is 3h, cool with furnace, grind Pulverize, cross 50 mesh sieves, obtain silicon carbide powder;

[0048] (3) Take graphene oxide and calcium nitrate solution, mix and stir for 10 minutes, add isopropanol solution, and ultrasonically disperse for 1 hour to obtain electrolyte;

[0049] The carbon fiber is used as the negative electrode, and the copper sheet is used as the positive electrode, and placed in the electrolyte for electrophoretic deposition. The deposition voltage is 120V, and the deposition time is 1 min. The carbon fiber is taken out, ultrasonically cleaned with deionized water for 5 m...

Embodiment 2

[0059] A method for preparing a high-strength wear-resistant polypropylene composite material, comprising the following steps:

[0060] (1) Prepare materials;

[0061] (2) Mix carbon powder and silicon dioxide, add ethanol solution to dissolve, ultrasonically disperse for 1.5h, vacuum dry at 75°C, vacuum sinter under argon atmosphere, sintering temperature is 1450°C, sintering time is 2.8h, and cool in the furnace , ground and pulverized, and passed through a 50-mesh sieve to obtain silicon carbide powder;

[0062] (3) Take graphene oxide and calcium nitrate solution, mix and stir for 15min, add isopropanol solution, and ultrasonically disperse for 1.5h to obtain electrolyte;

[0063] The carbon fiber is used as the negative electrode, and the copper sheet is used as the positive electrode, and placed in the electrolyte for electrophoretic deposition. The deposition voltage is 145V, and the deposition time is 1.5 minutes. The carbon fiber is taken out, ultrasonically cleaned ...

Embodiment 3

[0072] A method for preparing a high-strength wear-resistant polypropylene composite material, comprising the following steps:

[0073] (1) Prepare materials;

[0074] (2) Mix carbon powder and silicon dioxide, add ethanol solution to dissolve, ultrasonically disperse for 2 hours, vacuum dry at 80°C, vacuum sinter under argon atmosphere, sintering temperature is 1500°C, sintering time is 2.5h, and cool with the furnace. Grinding and pulverizing, passing through a 50-mesh sieve to obtain silicon carbide powder;

[0075] (3) Take graphene oxide and calcium nitrate solution, mix and stir for 20min, add isopropanol solution, and ultrasonically disperse for 2h to obtain electrolyte;

[0076] The carbon fiber is used as the negative electrode, and the copper sheet is used as the positive electrode, and placed in the electrolyte for electrophoretic deposition. The deposition voltage is 160V, and the deposition time is 1 min. The carbon fiber is taken out, ultrasonically cleaned with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com