Deodorizing and moisture-absorbing textile fabric and preparation method thereof

A technology of textile fabrics and fabrics, applied in the field of deodorant and moisture-absorbing textile fabrics and its preparation, can solve the problems that the deodorization and moisture absorption properties of fabrics cannot be effectively taken into account, and achieve excellent deodorization effects, excellent deodorization and moisture absorption properties, and reduce odors effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

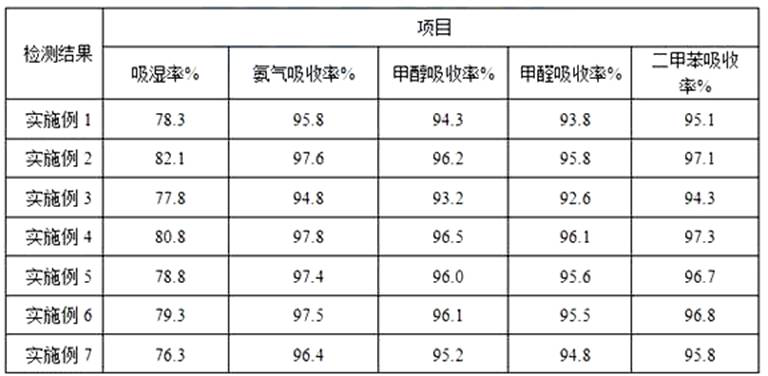

Examples

Embodiment 1

[0034] Preparation of cleaning powder: 2g nano-TiO 2 The particles were dispersed in 100mL deionized water, ultrasonicated for 3h, 15g of polyethylene glycol (PEG) was added, and mechanically stirred at 100rpm for 1h to obtain a dispersion.

[0035] Measure 300mL of polyvinyl alcohol aqueous solution with a concentration of 10wt%, add it to the dispersion, continue mechanical stirring for 1h, and stir to disperse to obtain a mixed solution; add 50mL of methanol dropwise to the mixed solution and stir, suction filter and wash to obtain a filter cake; Disperse the filter cake in 150 mL of absolute ethanol, stir it magnetically for 20 minutes, then filter it with suction, wash it repeatedly, put the filter cake in a watch glass, and grind the residual solvent naturally at room temperature, pass through a 200-mesh sieve to obtain a modified powder. The modified powder was placed in a crucible, calcined in a muffle furnace at 200°C for 2 hours, and then collected to obtain a clean ...

Embodiment 2

[0041] Preparation of cleaning powder: 4g nano-TiO 2 The particles were dispersed in 150mL deionized water, ultrasonicated for 4h, 20g of polyethylene glycol (PEG) was added, and mechanically stirred at 100rpm for 2h to obtain a dispersion.

[0042] Measure 400mL of polyvinyl alcohol aqueous solution with a concentration of 10wt%, add it to the dispersion liquid, continue mechanical stirring for 2h, stir and disperse to obtain a mixed liquid; add 100mL methanol dropwise to the mixed liquid and stir, suction filter and wash to obtain a filter cake; Disperse the filter cake in 150 mL of absolute ethanol, stir it magnetically for 30 minutes, then suction filter, wash repeatedly, put the filter cake in a watch glass, and grind the residual solvent naturally at room temperature, pass through a 200-mesh sieve to obtain the modified powder. The modified powder was placed in a crucible, calcined in a muffle furnace at 200°C for 4 hours, and then collected to obtain a clean powder.

...

Embodiment 3

[0048] Preparation of cleaning powder: 6g nano-TiO 2 The particles were dispersed in 200 mL of deionized water, ultrasonicated for 5 h, 25 g of polyethylene glycol was added, and mechanically stirred at 100 rpm for 3 h to obtain a dispersion.

[0049] Measure 500mL of polyvinyl alcohol aqueous solution with a concentration of 10wt%, add it to the dispersion liquid, continue to stir mechanically for 3h, stir and disperse to obtain a mixed liquid; add 150mL methanol dropwise to the mixed liquid and stir, suction filter and wash to obtain a filter cake; Disperse the filter cake in 150 mL of absolute ethanol, stir it magnetically for 40 minutes, then filter it with suction, wash it repeatedly, put the filter cake in a watch glass, and grind the residual solvent naturally at room temperature, pass through a 200-mesh sieve to obtain the modified powder. The modified powder was placed in a crucible, calcined in a muffle furnace at 200°C for 6 hours, and then collected to obtain a cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com