Crimping type IGBT sub-module and crimping type IGBT module

A crimping, sub-mold technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of high failure risk, complex structure, and high thermal resistance, reducing the number of stacked layers, simplifying the production process, and reducing the process. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

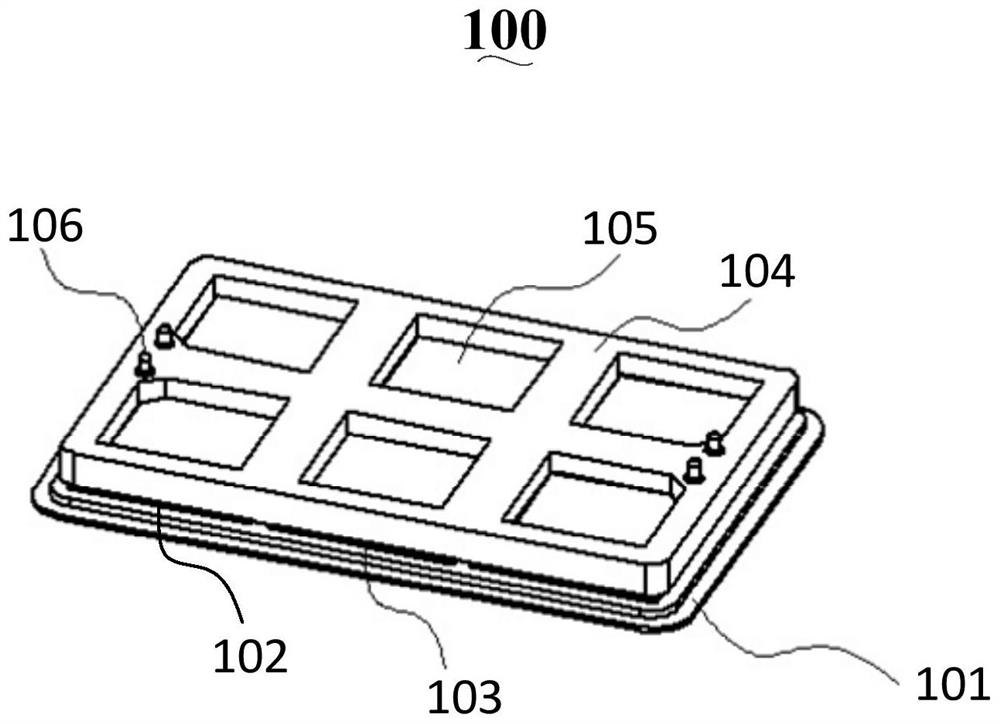

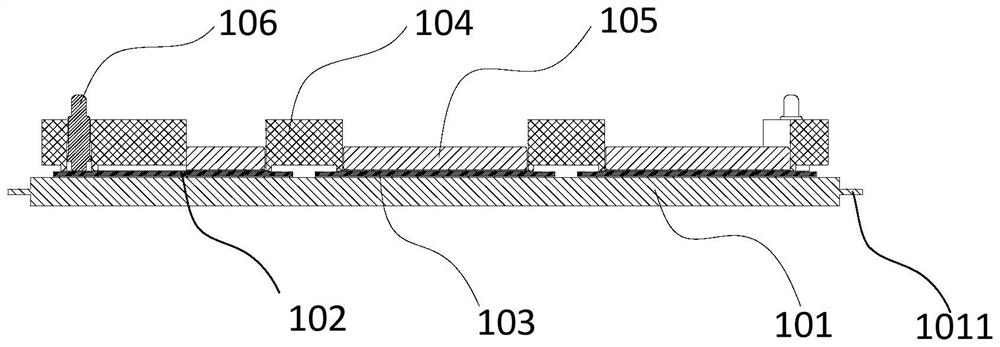

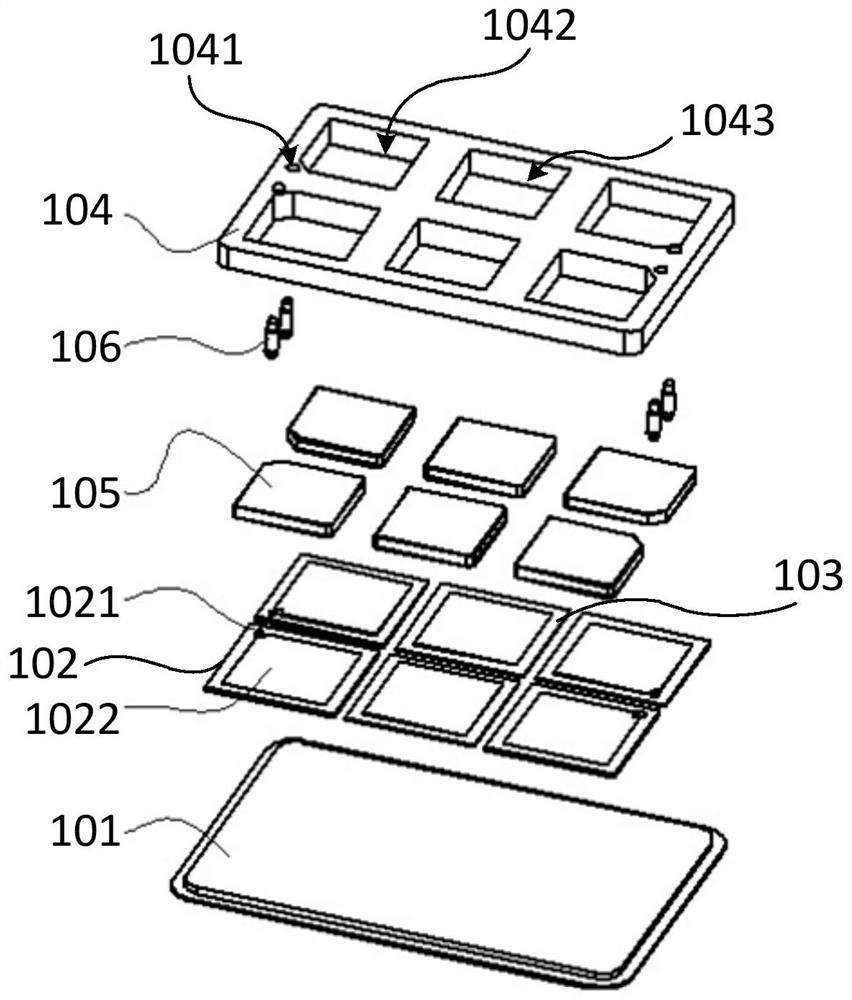

[0043] Such as figure 1 , figure 2 with image 3 As shown, this embodiment provides a crimp-type IGBT sub-module 100 , including a lower electrode plate 101 , an IGBT chip 102 , an FRD chip 103 , an insulating frame 104 , an upper electrode sheet 105 and a gate connector 106 .

[0044] The periphery of the lower electrode plate 101 (that is, the side wall of the lower electrode plate 101) is provided with a first skirt structure 1011, and the material of the lower electrode plate 101 can adopt high thermal conductivity, and the coefficient of thermal expansion (Coefficient of Thermal Expansion, CTE) and The matching materials of the IGBT chip 102 and the FRD chip 103 include (but not limited to) copper-molybdenum alloy or molybdenum.

[0045] A plurality of IGBT chips 102 and a plurality of FRD chips 103 are arranged above the lower electrode plate 101 at intervals. The number of IGBT chips 102 is greater than or equal to 2, and the number of FRD chips 103 is set according...

Embodiment 2

[0057] Such as Figure 4 with Figure 5 As shown, this embodiment provides a crimping type IGBT module on the basis of the first embodiment, including the crimping IGBT sub-module 100, the PCB circuit board 200 and the casing (not marked in the figure) in the first embodiment ).

[0058] The PCB circuit board 200 is located above the crimping type IGBT sub-module 100 . Wherein, the PCB circuit board 200 is in contact with the gate connector 106 of the press-fit IGBT sub-module 100, so as to gather the gates of all the press-fit IGBT sub-modules 100 to the total grid on the PCB circuit board 200 . The PCB circuit board 200 includes a plurality of fourth openings 201 for exposing the upper electrode pads 105 of each crimp-type IGBT sub-module 100 . That is to say, the PCB circuit board 200 is mainly used to lead out the gate of the crimp-type IGBT sub-module 100 .

[0059] The tube case includes a tube cover 300 and a tube base 400 , the tube cover 300 is located above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com