Non-PMR type polyimide carbon fiber prepreg, composite material and preparation method thereof

A polyimide carbon fiber and polyimide technology, applied in the field of polymer materials, can solve the problems of polyimide carbon fiber prepreg short storage period, complex molding process, environmental pollution, etc., and achieve low preparation cost, The effect of low porosity and excellent mechanical properties of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of non-PMR type polyimide carbon fiber prepreg of the present invention, step is as follows:

[0045] Step 1. Prepare polyimide prepreg

[0046] Stir and mix polyimide and solvent at 120-160°C until uniform, then cool to 50-80°C to obtain polyimide prepreg;

[0047] Step 2. Preparation of polyimide carbon fiber composite material

[0048] Use the polyimide prepreg obtained in step 1 to prepare a single-layer adhesive film, introduce unidirectional carbon fiber or carbon fiber cloth into the middle of the two-layer single-layer adhesive film, heat to 160-200°C and keep the temperature constant for 10-16h, cool to room temperature, Obtain polyimide carbon fiber prepreg;

[0049] Alternatively, evenly coat the polyimide prepreg obtained in step 1 on the surface of the carbon fiber fabric, heat to 160-200° C., and cool to room temperature to obtain a polyimide carbon fiber prepreg.

[0050] In the above technical scheme, in step 1, the polyimide is...

Embodiment 1

[0076] Step 1. Add dimethylacetamide to a reaction vessel with a heating and stirring device at a mass ratio of polyimide to dimethylacetamide of 60:40, raise the temperature to 150°C, and stir fully to The two form a uniform solution. After the mixing is completed, cool to 70°C at a rate of 3°C / min to obtain a polyimide prepreg;

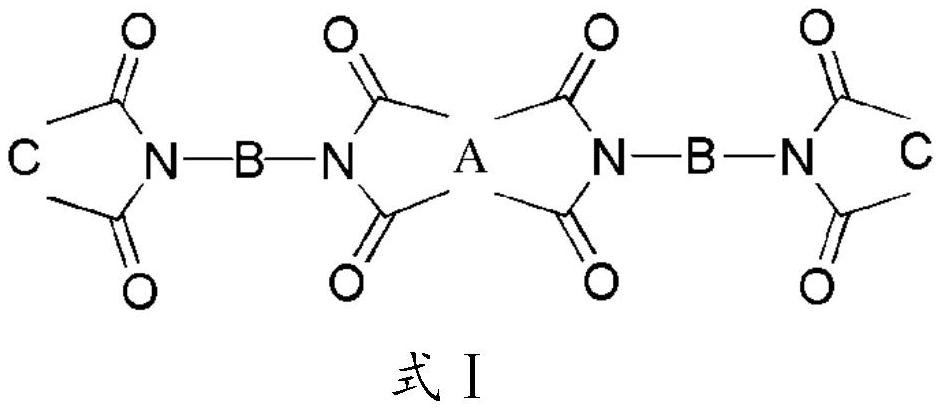

[0077] The structural formula of above-mentioned polyimide is as follows:

[0078]

[0079] Wherein, A is the following structure, or one of the isomers of the following structure:

[0080]

[0081] B is the following structure, or one of the isomers of the following structure:

[0082]

[0083] C is the following structure, or one of the isomers of the following structure:

[0084]

[0085] Step 2. Brush the polyimide prepreg obtained in step 1 evenly on the surface of high-strength carbon fiber cloth (strength 2GPa, modulus 250GPa), put it in an oven, heat to 170°C and keep the temperature constant for 12h, after removing the solvent...

Embodiment 2

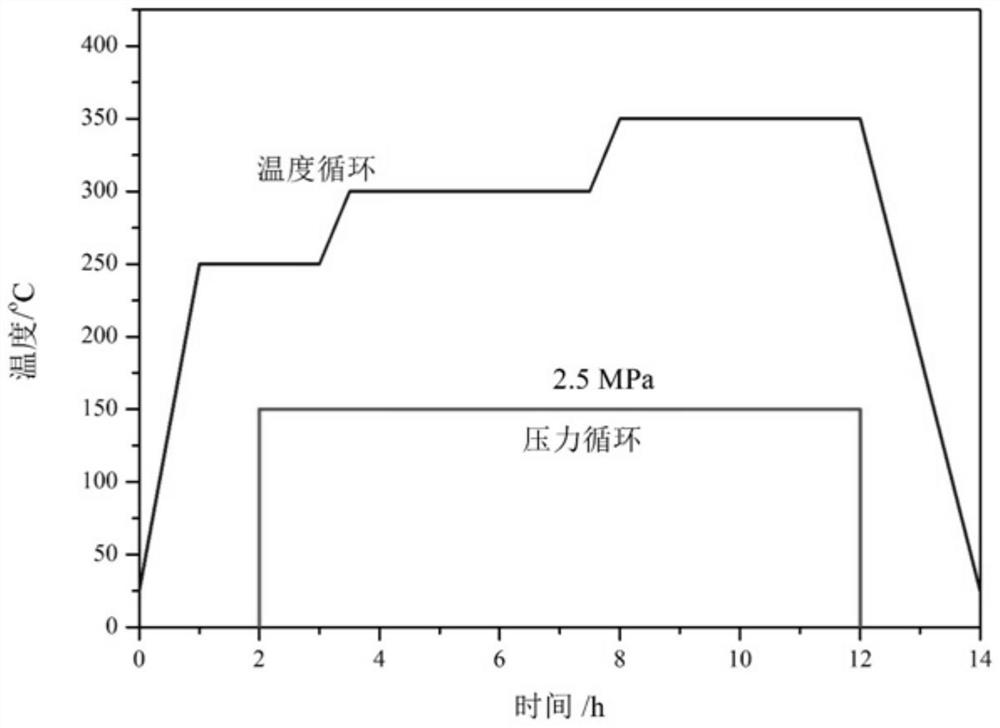

[0087] Spray methylene chloride on the surface of the polyimide carbon fiber prepreg prepared in Example 1 to soften it, then increase the temperature according to the gradient of 250°C / 2h+300°C / 4h+350°C / 4h, and control the clamping pressure to 2.5MPa. Molding (process conditions such as figure 1 Shown), obtain polyimide carbon fiber composite material.

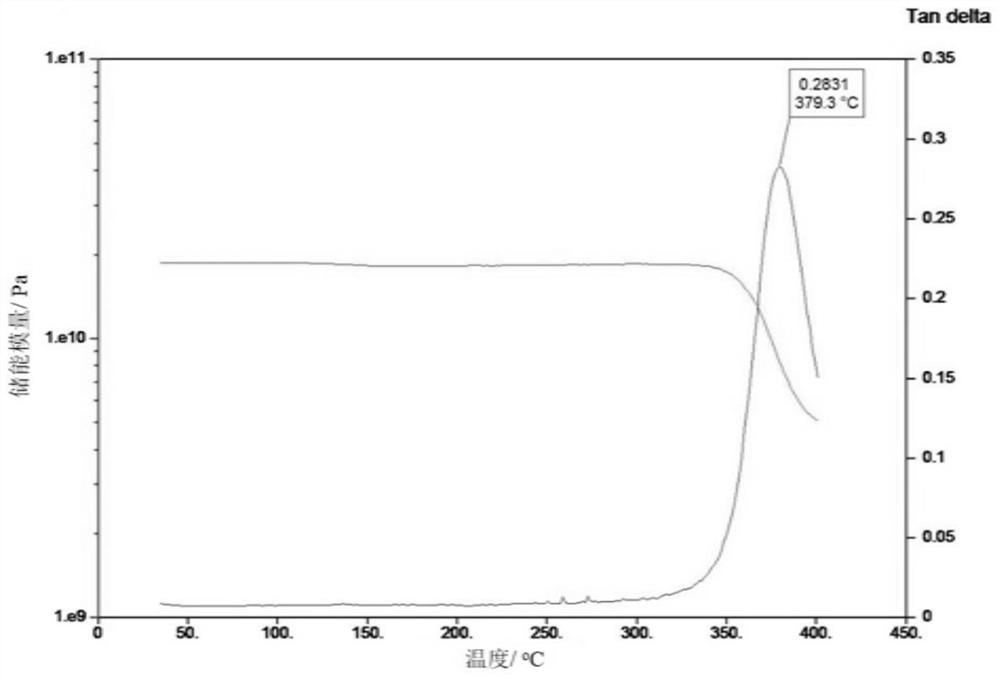

[0088] Adopt dynamic thermomechanical analyzer (DMA) to detect the polyimide carbon fiber composite material that embodiment 2 prepares, and detection result is as follows figure 2 shown, from figure 2 It can be seen that the storage modulus (E') of the polyimide carbon fiber composite material begins to decay at 330°C, and the Tan delta curve shows that the glass transition temperature of the material is as high as 379.3°C, which shows that the polyimide carbon fiber composite material Has good heat resistance.

[0089] The polyimide carbon fiber composite material prepared in Example 2 was tested by a universal testing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com