Solvent for removing underground heavy hydrocarbon deposition and preparation method thereof

A solvent and heavy hydrocarbon technology, applied in chemical instruments and methods, drilling compositions, ferrous oxides, etc., can solve the problems affecting the extraction and utilization of heavy hydrocarbon components, difficult to recycle, etc. Improve dissolving ability and viscosity reducing effect, promote dissolving and reduce viscosity, relieve the effect of heavy hydrocarbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a solvent for removing downhole heavy hydrocarbon deposition, comprising the steps of:

[0031] S1. Preparation of Fe by co-precipitation method 3 o 4 nanoparticles;

[0032] S2, the Fe obtained in step S1 3 o 4 Nanoparticles dispersed in acetonitrile to obtain Fe 3 o 4 Nanoparticle suspension; Add thiophene monomer to the Fe3 o 4 Nanoparticle suspension, and add the acetonitrile solution of potassium permanganate, get polythiophene-coated Fe after full reaction 3 o 4 nanoparticles;

[0033] S3, mixing 1,3-dibromopropane and diethylamine according to a preset molar ratio and then dissolving in water, recovering the oil phase after sufficient alkylation reaction, and obtaining a first solvent with a diamine structure after heating to remove impurities;

[0034] S4, the Fe coated with polythiophene obtained in step S2 3 o 4 The nanoparticles are dispersed in ethanol, and then the first solvent, octylamine and ethoxy...

Embodiment 1

[0045] This embodiment provides a method for preparing a solvent for removing downhole heavy hydrocarbon deposition, comprising the following steps:

[0046] S1. Under a nitrogen atmosphere, mix ferrous chloride and ferric chloride according to a molar ratio of 1:2.5 and dissolve them in deionized water, then add ammonia water with a mass fraction of 25wt%, collect the precipitate after the reaction is complete, wash, After drying, Fe 3 o 4 nanoparticles.

[0047] S2, 1g of the Fe obtained in step S1 3 o 4 Nanoparticles were added into 10mL acetonitrile and ultrasonically dispersed for 10min to obtain Fe 3 o 4 nanoparticle suspension; then 2 mL of thiophene monomer was added to the Fe 3 o 4 During the stirring process, add 50mL of potassium permanganate solution in acetonitrile with a concentration of 5mmol / L drop by drop, after fully reacting for 3 hours, collect the precipitate, wash and dry it to obtain the poly Thiophene-coated Fe 3 o 4 nanoparticles.

[0048] S...

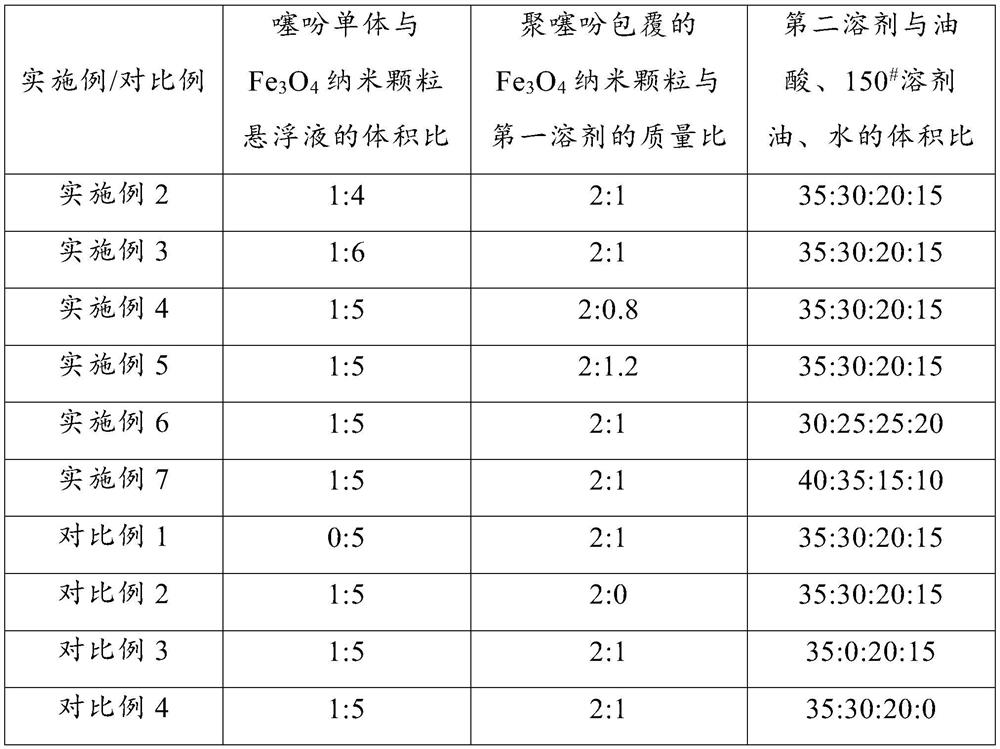

Embodiment 2~7 and comparative example 1~4

[0052] Embodiments 2 to 7 and comparative examples 1 to 4 respectively provide a method for preparing a solvent for removing downhole heavy hydrocarbon deposition. Compared with Example 1, the difference is that the thiophene monomer and Fe in step S2 are changed. 3 o 4 The volume ratio of the nanoparticle suspension, the Fe coated with polythiophene in step S4 3 o 4 The mass ratio of nanoparticles and the first solvent and the second solvent and oleic acid, 150 in step S5 # The volume ratio of mineral spirits, water, all the other steps are consistent with embodiment 1, do not repeat them here. The preparation parameters corresponding to Examples 2-7 and Comparative Examples 1-4 are shown in Table 1.

[0053] The preparation parameter of table 1 embodiment 2~7 and comparative example 1~4

[0054]

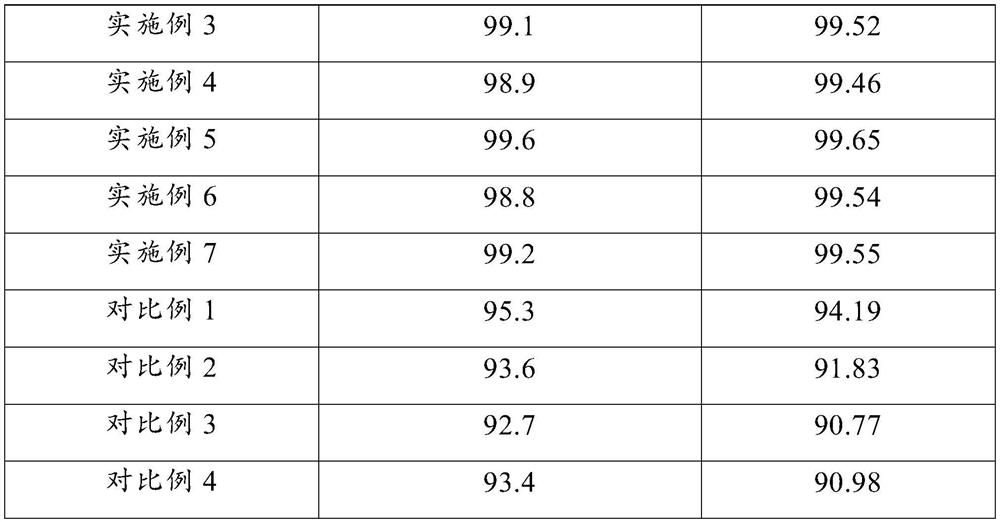

[0055] According to the methods provided in Examples 1 to 7 and Comparative Examples 1 to 4, prepare corresponding solvents for removing downhole heavy hydrocarbon depositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com