Preparation process of corn edible oil

A preparation process and edible oil technology, which is applied in the field of edible oil, can solve problems such as difficulty in ensuring oil yield, reducing the content of Aspergillus flavus, and difficulty in improving the smell and taste of finished oil and oil yield, so as to improve extraction rate, purity, Fragrance lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of corn edible oil, this corn edible oil is made up of following percentage raw material:

[0042]Corn germ powder 35%, whole corn 35%, citric acid 3%, cellulase 2%, α-amylase 2%, cashew nut oil 4%, rapeseed oil 4%, white sesame 5%, perilla seed 6 % and liquor 2%.

Embodiment 2

[0044] A kind of corn edible oil, this corn edible oil is made up of following percentage raw material:

[0045] Corn germ powder 37.5%, whole corn 37.5%, citric acid 4%, cellulase 2.5%, α-amylase 2.5%, cashew nut oil 5%, rapeseed oil 5%, white sesame 7%, perilla seed 8 % and liquor 2.5%.

Embodiment 3

[0047] A kind of corn edible oil, this corn edible oil is made up of following percentage raw material:

[0048] Corn germ powder 40%, whole corn 40%, citric acid 5%, cellulase 3%, α-amylase 3%, cashew nut oil 6%, rapeseed oil 6%, white sesame 8%, perilla seed 10 % and liquor 3%.

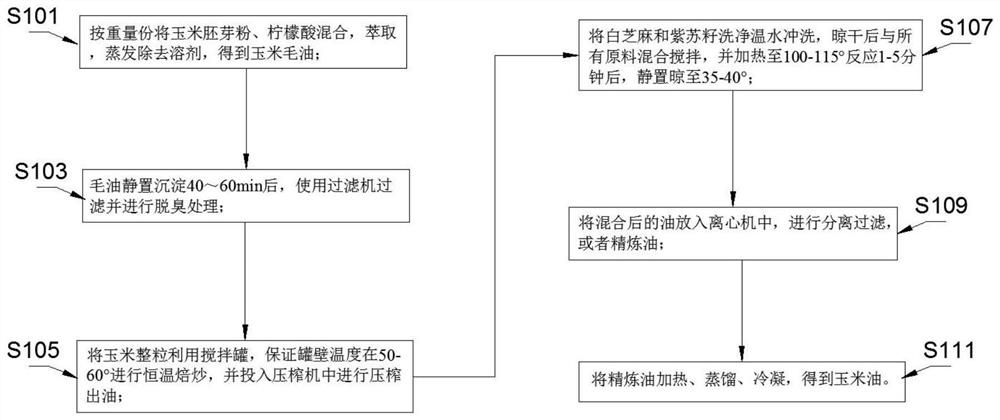

[0049] In order to facilitate the understanding of the above-mentioned technical solution of the present invention, the flow process of the above-mentioned solution of the present invention will be described in detail below in conjunction with the accompanying drawings, specifically as follows:

[0050] According to an embodiment of the present invention, a kind of preparation technology of corn edible oil is also provided, comprising the following steps:

[0051] Step S101: mixing corn germ powder and citric acid in parts by weight, extracting, and evaporating to remove the solvent to obtain crude corn oil;

[0052] Step S103: After the crude oil is left to settle for 40-60 minutes, filter it wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com