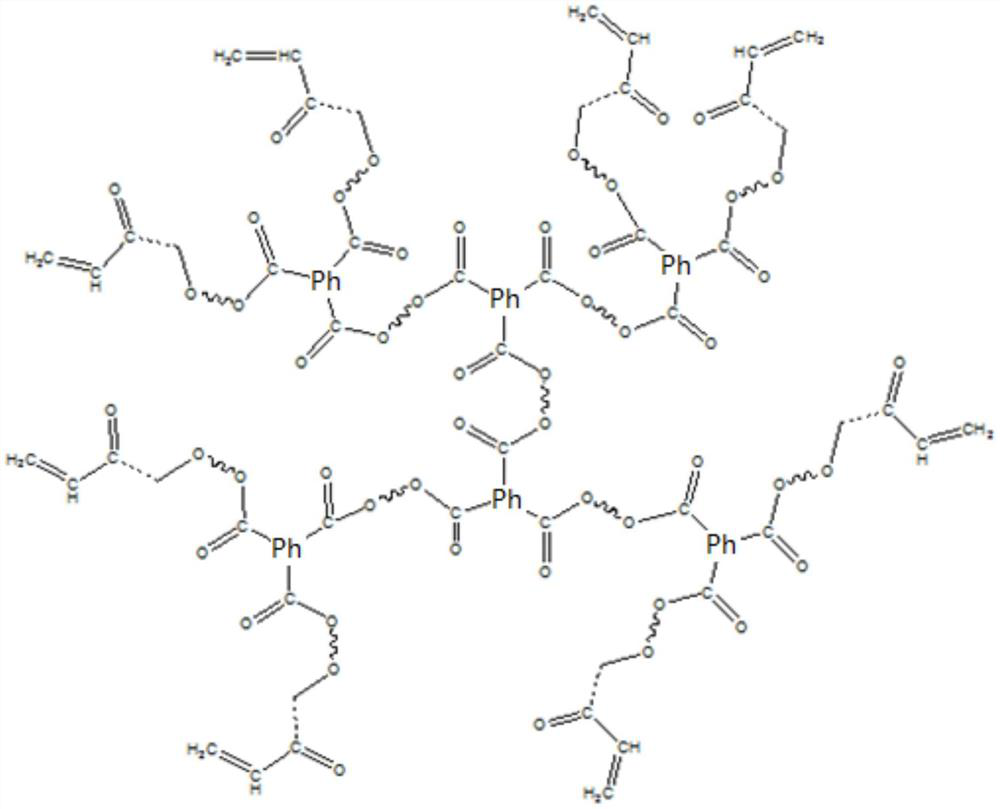

Network-structure short-chain fluorine-containing waterproof and oil-proof copolymer and preparation method thereof

A waterproof and oil-proof, network structure technology, applied in the direction of fiber type, textile and papermaking, fiber processing, etc., can solve the problems of high price, difficult degradation of PFOA/PFOS, bioaccumulative environmental hazards, etc., to achieve large steric hindrance, Good waterproof and oil-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

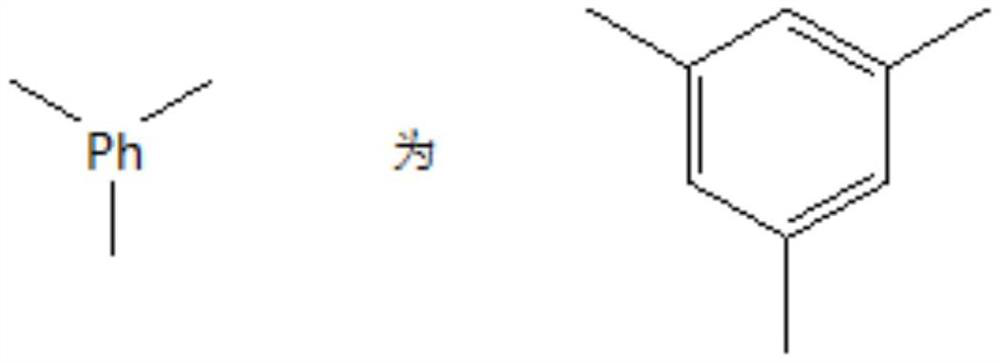

[0041] In a preferred embodiment, the present invention provides a kind of preparation method of network structure short-chain fluorine-containing waterproof and oil-repellent copolymer, it comprises the steps:

[0042] 1) dissolving the nonionic surfactant and the cationic surfactant in a mixed solution of water and an organic solvent to prepare a solution;

[0043] 2) adding the pre-mixed solution of the comonomer into the solution of step 1), and high shearing to make a pre-emulsion;

[0044] 3) Warm up the pre-emulsion in step 2) to 70-90°C, add an initiator to initiate, and keep warm for 2-4h;

[0045] 4) Cool down to room temperature, adjust pH to 2-4 with acetic acid and collect.

[0046] In a more preferred embodiment, said nonionic surfactant comprises isomerism (C 10 -C 13 ) alcohol polyoxyethylene ether (5-20EO), C 8 -C 20 Fatty alcohol polyoxyethylene ether (15-40EO), or their mixture; the cationic surfactant includes dodecyltrimethylammonium chloride, dodecyl...

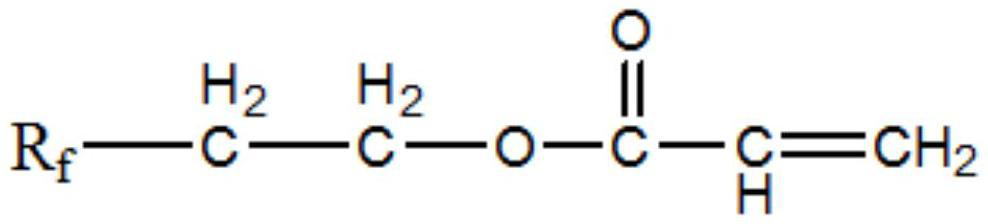

Embodiment 1

[0068] 21g of 1,3,5-benzenetricarboxylic acid and 38g of 1,14-tetradecanediol were reacted at 220°C for 4 hours under the catalysis of 0.12g of tetra-n-butyl titanate, and then 7.92g of acrylic acid and 0.1g of titanic acid were added Tetra-n-butyl ester and 0.4 g of hydroquinone were reacted at 220° C. for 3 h and cooled to room temperature to be used as comonomer 1.

[0069] Stir and dissolve 1.0g fatty alcohol polyoxyethylene ether (10EO) and 0.8g cetyltrimethylammonium bromide in a mixed solution of 68.8g deionized water and 7g ethylene glycol monobutyl ether, then mix 10g of the above Comonomer 1, 3.5g of octadecyl acrylate, 6.0g of perfluorobutyl ethyl acrylate, 0.5g of hydroxyethyl acrylate were mixed evenly and then added, the temperature was raised to 70°C, and after complete dissolution, high shear was used to obtain pre-emulsion 1 .

[0070] Add 2.4g of 10% azobisisobutylamidine hydrochloride solution slowly (control the stable change not to be higher than 5°C) dro...

Embodiment 2

[0072] 21g of 1,3,5-benzenetricarboxylic acid and 24g of 1,3-octanediol were reacted at 220°C for 4h under the catalysis of 0.1g of tetra-n-butyl titanate, and then 7.92g of acrylic acid and 0.1g of tetra-titanate were added. n-Butyl ester and 0.4g of hydroquinone were reacted at 220°C for 3h, then cooled down to room temperature, as comonomer 2.

[0073] 0.9g of isomeric tridecyl alcohol polyoxyethylene ether (15EO), 0.7g of octadecyltrimethylammonium chloride were stirred and dissolved in 70g of deionized water and 6g of propylene glycol mixture, and then 11.4g of the above-mentioned comonomer 2. 3.3g of n-butyl acrylate, 4.5g of perfluorohexyl ethyl acrylate, and 0.8g of glycidyl acrylate were mixed evenly and then added, the temperature was raised to 70°C, and after complete dissolution, pre-emulsion 2 was obtained by high shearing.

[0074] Add 2.4g of 10% azobisisobutylamidine hydrochloride solution slowly (control the stable change not to be higher than 5°C) dropwise in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com