Functional organic porous polymer as well as preparation method and application thereof

A porous polymer and functional technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of cumbersome synthesis steps, single function, long reaction cycle, etc., and achieve simple preparation methods, simplified experimental steps, high iodine The effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation method of a functional organic porous polymer, comprising the following steps:

[0047] (1) Under the protection of an inert gas, using tetrakis (4-bromophenyl) silane (1 molar equivalent), 1,4-diethynylbenzene (2 molar equivalents), and tert-butyl isocyanide (4 molar equivalents) as raw materials, Under the catalysis of palladium acetate (0.1 molar equivalents) and bis(2-diphenylphosphophenyl) ether (0.2 molar equivalents), cesium carbonate (4.2 molar equivalents) was used as the acid absorbent, and in N,N-dimethyl In methyl formamide, heat reaction at 100°C for 72h;

[0048] (2) After the reaction is completed, filter and wash the filter cake successively with chloroform, acetone, methanol, water and tetrahydrofuran, then the solid powder is eluted under reflux conditions with a Soxhlet extractor, using methanol and tetrahydrofuran as eluents After elution for 24 hours, functional organic porous polymer A was obtained after vacuum drying at 70° C. for 2...

Embodiment 2

[0051] A preparation method of a functional organic porous polymer, comprising the following steps:

[0052] (1) Under the protection of an inert gas, using tetrakis (4-iodophenyl) silane (1 molar equivalent), 1,4-diethynylbenzene (2 molar equivalents), and tert-butyl isocyanide (2.8 molar equivalents) as raw materials, Under the catalysis of tetrakis(triphenylphosphine)palladium (0.05 molar equivalent), potassium carbonate (4.2 molar equivalent) was used as an acid absorbent, and heated in N,N-dimethylformamide at 100°C for 72h;

[0053] (2) After the reaction is completed, filter and wash the filter cake successively with chloroform, acetone, methanol, water and tetrahydrofuran, then the solid powder is eluted under reflux conditions with a Soxhlet extractor, using methanol and tetrahydrofuran as eluents Each was eluted for 24 hours, and functional organic porous polymer B was obtained after vacuum drying at 70° C. for 24 hours, with a yield of 97.6%.

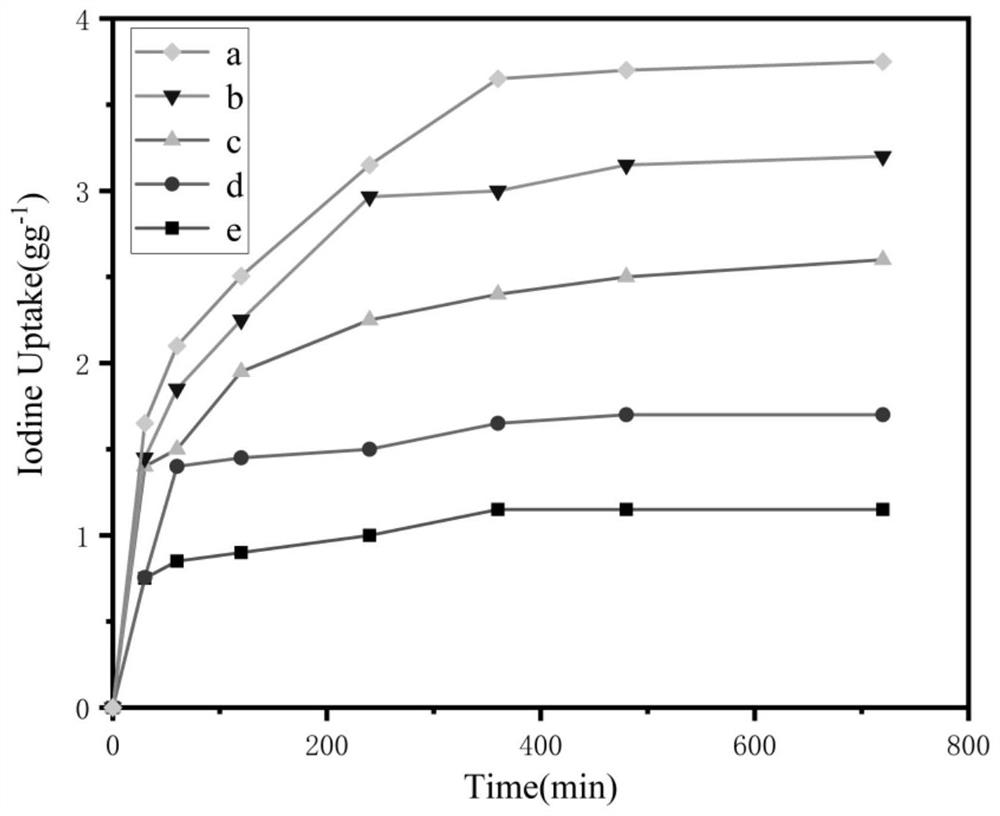

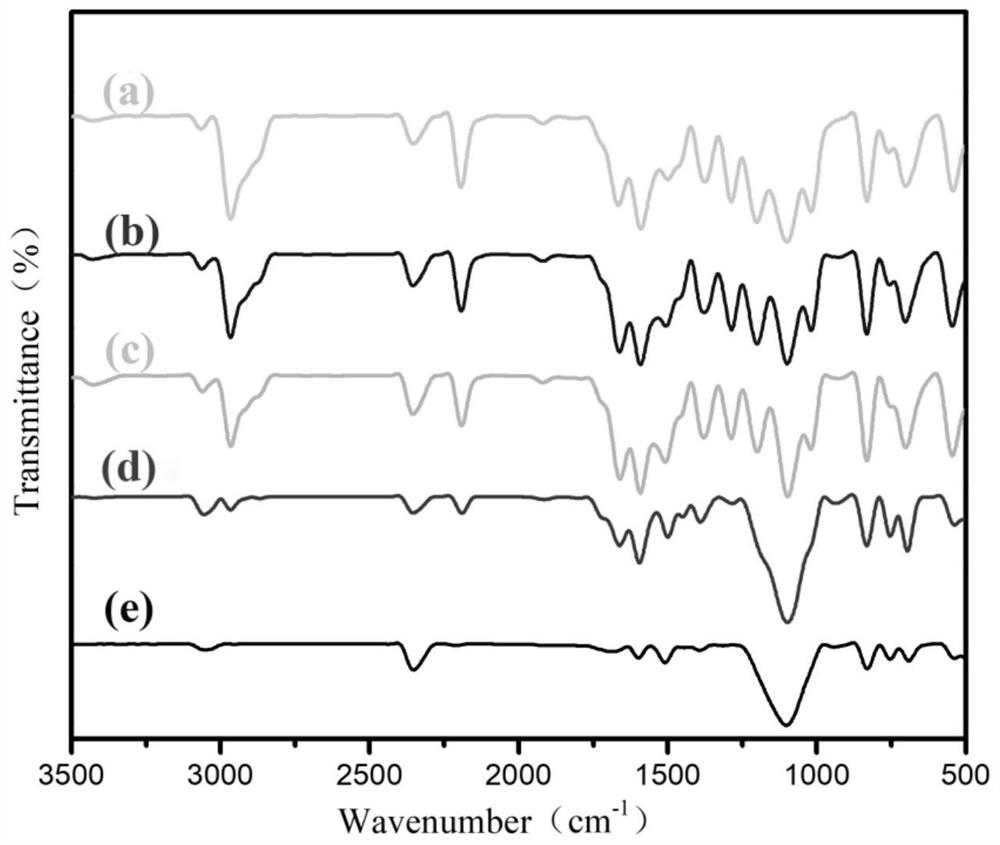

[0054] figure 1 Mid...

Embodiment 3

[0056] A preparation method of a functional organic porous polymer, comprising the following steps:

[0057] (1) Under the protection of an inert gas, using tetrakis (4-bromophenyl) silane (1 molar equivalent), 1,4-diethynylbenzene (2 molar equivalents), and tert-butyl isocyanide (2 molar equivalents) as raw materials, Under the catalysis of palladium acetate (0.1 molar equivalents) and bis(2-diphenylphosphophenyl) ether (0.2 molar equivalents), triethylamine (4.2 molar equivalents) was used as the acid absorbent, and the N,N-di In methylformamide, heat reaction at 100°C for 72h;

[0058] (2) After the reaction is completed, filter and wash the filter cake successively with chloroform, acetone, methanol, water and tetrahydrofuran, then the solid powder is eluted under reflux conditions with a Soxhlet extractor, using methanol and tetrahydrofuran as eluents Each was eluted for 24 hours, and functional organic porous polymer C was obtained after vacuum drying at 70° C. for 24 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Iodine adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com