Spinning-solution-colored three-dimensional crimped hollow PTT fibers and preparation method thereof

A three-dimensional crimping and dope coloring technology, applied in hollow filament manufacturing, fiber processing, fiber chemical characteristics, etc., can solve problems such as restricting the development and application of PTT fibers, serious product homogeneity, and hard fiber feel, and achieve resilience. Good, soft feel, free from environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

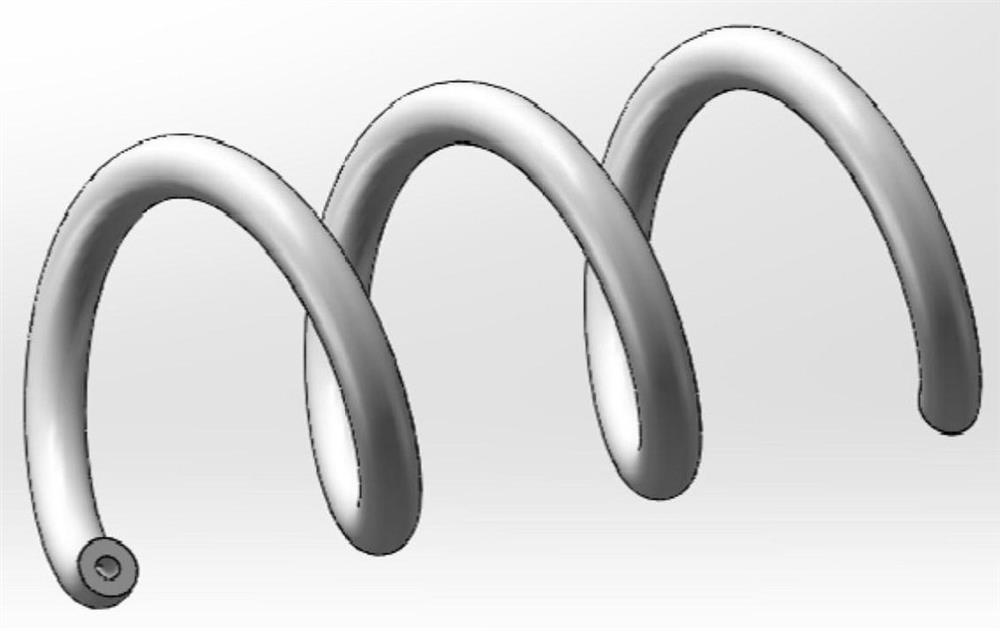

Image

Examples

Embodiment 1

[0056] Preparation of blue three-dimensional crimped hollow PTT fibers

[0057] The first step, the preparation of PTT carrier blue masterbatch

[0058] Add 6g of C.I. Pigment Blue 10 powder and 94g of 3-glycidyl etheroxypropyltrimethoxysilane coupling agent powder into the tank of the high-energy nano-impact mill tank by weight percentage 6%:94%, and add Φ8mm zirconia ball mill Medium 114g, the weight ratio of Φ8mm zirconia ball milling medium to the environmental pigment is 95%:5%; stop the ball milling after 2 hours of continuous ball milling, put the powder into the bag through the sieve and tie the bag tightly to obtain the environmental pigment powder; The average particle size of the fiber-grade pigment powder is 0.8-1.0um, and it is 0.4-0.5um after grinding.

[0059] Remove water from the PTT slices with a melting point of 228°C and an intrinsic viscosity of 1.034dl / g and cool them to room temperature, then put them into the tank of a high-energy nano-impact mill, and...

Embodiment 2

[0072] Preparation of yellow three-dimensional crimped hollow PTT fibers

[0073] The first step, the preparation of PTT carrier yellow masterbatch

[0074] Put 5g of Pigment Yellow 138 powder and 95g of 3-glycidyl etheroxypropyltrimethoxysilane coupling agent powder into the tank body of the high-energy nano-impact grinding tank according to the weight percentage of 5%:95%, and add Φ8mm zirconia ball milling medium 114g, the weight ratio of Φ8mm zirconia ball milling medium to environmental pigment is 95%:5%; stop the ball milling after 2 hours of continuous ball milling, put the powder into the bag through the sieve and tie the bag tightly to obtain the environmental pigment powder; fiber The average particle size of the pigment powder is 0.8-1.0um, and it is 0.4-0.5um after grinding, no special instructions are required.

[0075] Remove water from the PTT slices with a melting point of 228°C and an intrinsic viscosity of 1.034dl / g and cool them to room temperature, then pu...

Embodiment 3

[0087] Preparation of green three-dimensional crimped hollow PTT fibers

[0088] The first step, the preparation of PTT carrier yellow masterbatch

[0089] Add 6g of C.I Pigment Green 8 powder and 94g of 3-glycidyl etheroxypropyl trimethoxysilane coupling agent powder into the tank of the high-energy nano-impact mill tank by weight percentage 6%:94%, and add Φ8mm zirconia ball mill Medium 114g, the weight ratio of Φ8mm zirconia ball milling medium to the environmental pigment is 95%:5%; stop the ball milling after 2 hours of continuous ball milling, put the powder into the bag through the sieve and tie the bag tightly to obtain the environmental pigment powder; The average particle size of fiber-grade pigment powder is 0.8-1.0um, and after grinding, it is 0.4-0.5um, no special instructions are required.

[0090] Remove water from the PTT slices with a melting point of 228°C and an intrinsic viscosity of 1.034dl / g and cool them to room temperature, then put them into the tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com