Magnetic ionic liquid nano-composite adsorption material for CO2 capture

A magnetic ionic liquid and nano-composite technology, applied in gas treatment, separation methods, alkali metal compounds, etc., can solve the problems of high price of ionic liquids, obstacles to large-scale application of ionic liquids, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

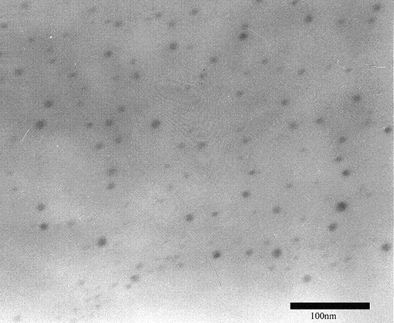

Image

Examples

Embodiment 1

[0033] 1.148molFeCl 3 .6H 2 O with 0.574molFeCl 2 .4H 2 O was added to 2.296mol [Bmim]Cl under nitrogen protection, and mechanically stirred to mix thoroughly. After the temperature was stabilized at 70°C, 400ml of concentrated ammonia water was gradually added dropwise to the system. Fe 3 o 4 Washed several times with 50% ethanol aqueous solution and deionized water, then magnetically separated, and vacuum-dried to obtain powdery particles.

[0034] 10 g of pan80 was dissolved in 1.0M hydrochloric acid at room temperature, 50 g of mesitylene and 100 mg of ammonium fluoride were added thereto, and the mixture was heated to 37°C with stirring for 30 min. 30g of ethyl silicate and 20g of Fe 3 o 4 Added into it and heated to 100°C for 20h, the mixture was cooled to room temperature, magnetically separated to obtain a solid product, dried in air and calcined at 400°C for 16 hours.

[0035] A certain amount of tetramethylammonium hydroxide glycinate ionic liquid and the ca...

Embodiment 2

[0042] 1.148molFeCl 3 .6H 2 O with 0.574molFeCl 2 .4H 2 O was added to 2.296mol [Bmim]Cl under nitrogen protection, and mechanically stirred to mix thoroughly. After the temperature was stabilized at 70°C, 400ml of concentrated ammonia water was gradually added dropwise to the system. Fe 3 o 4 Washed several times with 50% ethanol aqueous solution and deionized water, then magnetically separated, and vacuum-dried to obtain powdery particles.

[0043] 10 g of tween80 was dissolved in 0.8M hydrochloric acid at room temperature, 20 g of mesitylene and 200 mg of ammonium fluoride were added thereto, and the mixture was heated to 40°C with stirring for 60 min. 40g of ethyl silicate and 30g of Fe3O4 were added thereto and heated to 100°C for 24h, the mixture was cooled to room temperature, magnetically separated to obtain a solid product, dried in air and calcined at 420°C for 8 hours.

[0044] A certain amount of n-butylammonium lysine salt ionic liquid and the carrier were ...

Embodiment 3

[0048] Add 1.148mol FeCl3.6H2O and 0.574mol FeCl2.4H2O to 2.296mol [Bmim]Cl under nitrogen protection, and mix thoroughly with mechanical stirring. After the temperature was stabilized at 70°C, 400ml of concentrated ammonia water was gradually added dropwise to the system. Fe3O4 was washed several times with 50% ethanol aqueous solution and deionized water, then magnetically separated, and dried in vacuum to obtain powdery particles.

[0049] Dissolve 20 g of bis(2-ethylhexyl) sodium sulfosuccinate in 0.001M hydrochloric acid at room temperature, add 10 g of mesitylene and 150 mg of ammonium fluoride and heat the mixture to 38°C under stirring , maintain 90min. 30g NaHSi2O5.3H2O and 25g Fe3O4 were added thereto and heated to 120°C for 22h, the mixture was cooled to room temperature, magnetically separated to obtain a solid product, dried in air and calcined at 450°C for 8 hours.

[0050] A certain amount of tetrahexylammonium hydroxide threonine salt ionic liquid and the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com