Electrode spray device, carbon nanotube reactor and carbon nanotube preparation method

A carbon nanotube and reactor technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of low carbon source conversion rate, small operation space, high price, etc. The effect of improving productivity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

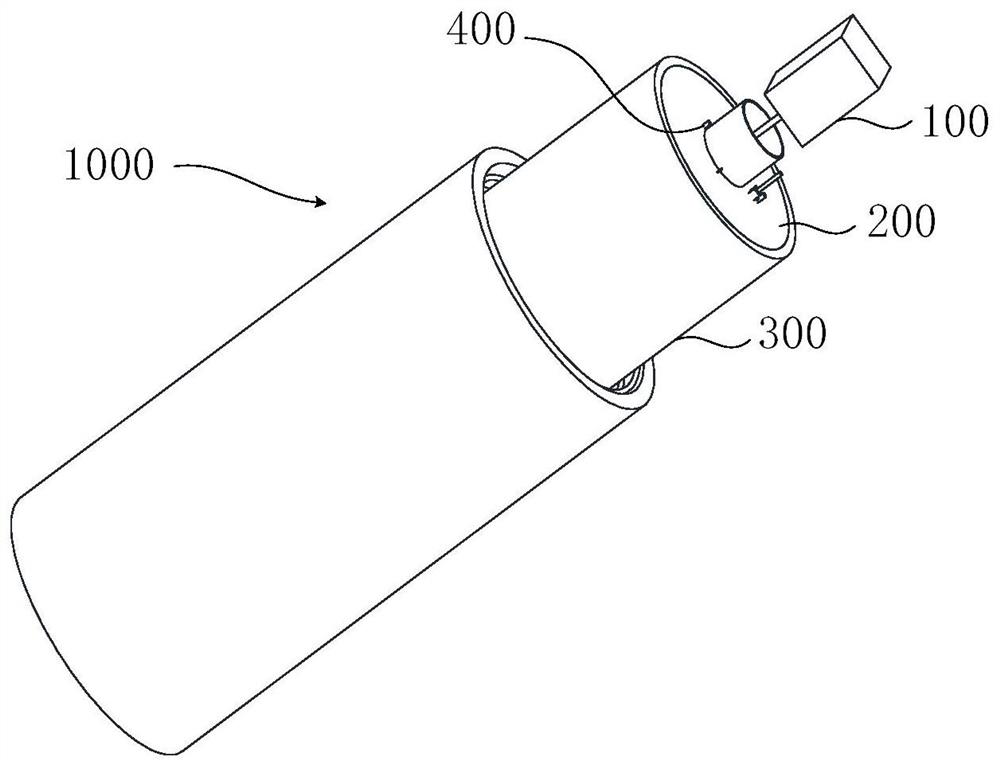

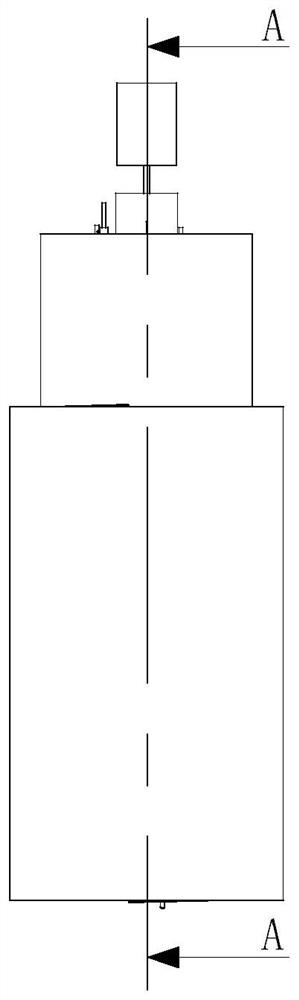

[0060] see Figure 1-7 , Embodiment 1 provides an electrode spray device 100 . The electrode spray device 100 is provided with a storage container 110 , a squeezer 120 and an electrode assembly 130 . The storage container 110 has a carbon source accommodating space, one end of which is provided with an extrusion opening, and the other end is provided with an extrusion opening; the extruder 120 is arranged at the extrusion opening; the extrusion part is provided with the carbon source accommodating space The extrusion port is connected in space, and the electrode assembly 130 is provided at the extrusion port; the storage container 110 is also provided with a feeding pipe 111 .

[0061] The electrode assembly 130 includes a first electrode 131 and a second electrode 132. The first electrode 131 is connected to the extrusion part and provides an electric field for the extrusion opening; the second electrode 132 is provided with a through opening facing the extrusion part, A di...

Embodiment 2

[0063] Embodiment 2 provides an electrode ejection device 100, the structure of which is based on Embodiment 1 and adds a third electrode 133; the third electrode 133 is provided with an annular opening facing the extrusion port, and is sleeved on the first electrode 131 , and a distance of 2-30 mm is set between it and the second electrode 132 .

Embodiment 3

[0065] see Figure 1-7 , Example 3 provides a carbon nanotube reactor 1000. The reactor 1000 includes an electrode spray device 100 , a cover plate 200 , a reaction chamber 300 and a protective gas pipeline 400 . The reaction chamber 300 is provided with a reaction accommodating chamber, one end of which is provided with a reaction opening communicating with the reaction accommodating chamber; the cover plate 200 is provided with a discharge port and is sealed and covered on the reaction opening; the electrode spray device 100 is provided with At the reaction opening, the cover plate 200 is sleeved on the outside of the storage container 110; the protective gas pipeline 400 is arranged on the cover plate 200 and communicated with the discharge port, see Figure 4 .

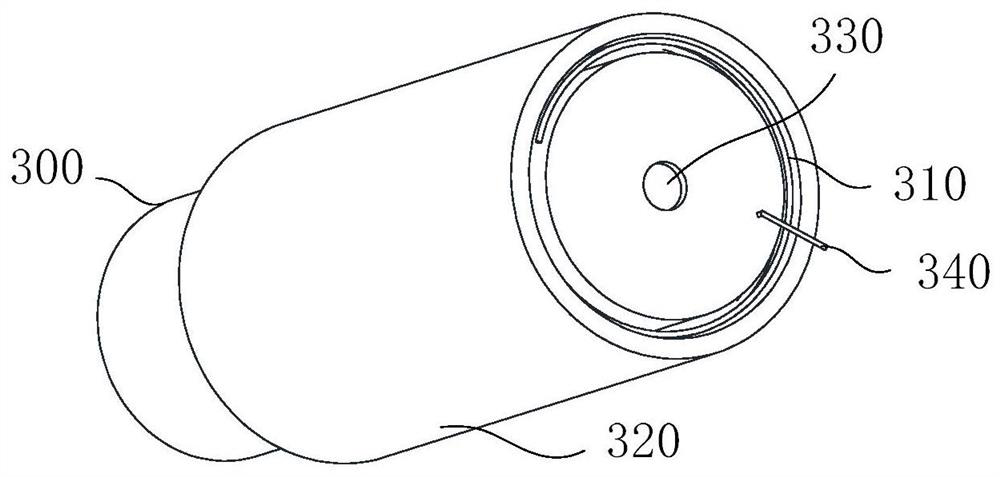

[0066] The reaction chamber 300 is provided with a product discharge port 330 and an air pressure balance opening 340, and a heating layer 310 and a thermal insulation layer 320 are sleeved outside, see figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com