Si3N4 whisker toughened high-thermal-conductivity AlN ceramic substrate and preparation method thereof

A ceramic substrate, high thermal conductivity technology, applied in the field of whisker toughening ceramic substrate materials, can solve the problems of reducing the fracture toughness and reliability of aluminum nitride ceramics, and achieves improved thermal stability and reliability, dense structure, The effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

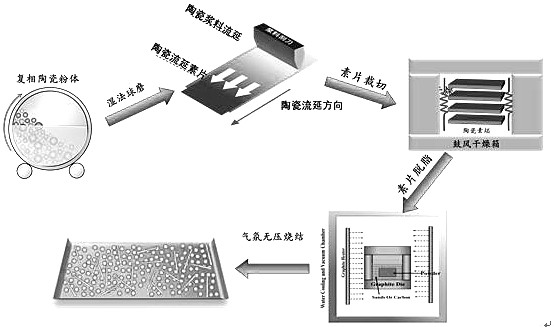

[0025] like figure 1 As shown, a preparation method of a Si3N4 whisker-toughened high thermal conductivity AlN ceramic substrate comprises the following steps: the first step: aluminum nitride powder, yttrium oxide, polyazilane fiber, polyethylene glycol butyral , polyethylene glycol and ethanol are mixed, and the mixed slurry is obtained under a water bath; the second step: put the mixed slurry into a polytetrafluoroethylene tank for ball milling, and the third step: after the ball milled slurry is sieved and defoamed The cast slurry is obtained; the fourth step: the cast slurry is passed through the casting process to obtain the composite ceramic film; the fifth step: the composite ceramic film obtained in the fourth step is put into the degreasing furnace for debinding, and the composite ceramic film is obtained The plain sheet; the sixth step: sintering the plain sheet of the composite ceramic obtained in the fifth step under a nitrogen atmosphere to obtain a product.

[...

Embodiment 1

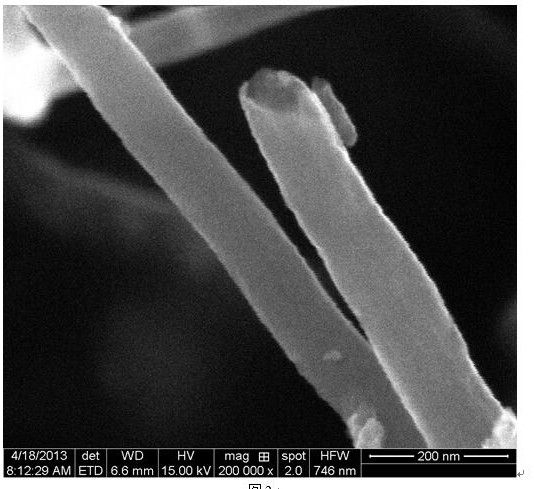

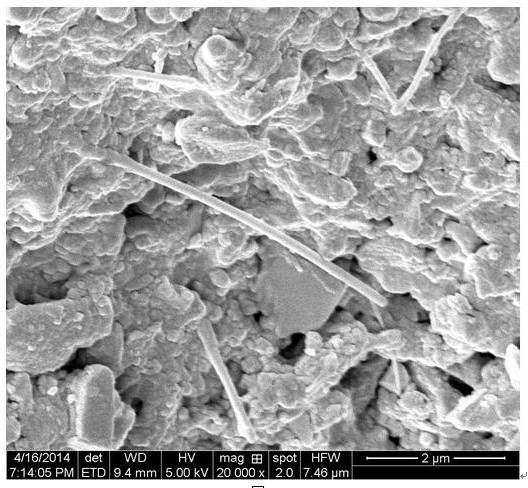

[0030] Aluminum nitride powder, yttrium oxide, polyazilane fiber, polyethylene glycol butyral, polyethylene glycol and ethanol are mixed according to the mass ratio of 1:0.03:0.1:3:2:20, the aluminum nitride The average particle diameter of the powder is 1 μm; the average particle diameter of the yttrium nitride is 0.5 μm; the diameter of the polyazide silane fiber is 1 μm, and the average length is 50 μm; the polymerization degree of the polyethylene glycol butyral is 2000, the molecular weight of the polyethylene glycol is 4000, wherein yttrium oxide is used as a sintering aid, and magnetic stirring is carried out in a water bath at 70° C. for 1 h to obtain a mixed slurry; then the mixed slurry is put into a polytetrafluoroethylene tank for ball milling for 8 h, The ball milling medium is aluminum nitride balls. After the ball milling, the slurry is sieved and defoamed to obtain the casting slurry; the casting slurry is passed through the casting process to obtain a multi-pha...

Embodiment 2

[0033]Aluminum nitride powder, yttrium oxide, polyazilane fiber, polyethylene glycol butyral, polyethylene glycol and ethanol are mixed according to the mass ratio of 1:0.03:0.1:3:2:20, the aluminum nitride The average particle size of the powder is 1.1 μm; the average particle size of the yttrium nitride is 0.4 μm; the diameter of the polyazide silane fiber is 1.1 μm, and the average length is 45 μm; the polymerization of polyethylene glycol butyral The molecular weight of the polyethylene glycol is 2100; the molecular weight of the polyethylene glycol is 3600, and yttrium oxide is used as a sintering aid, and magnetic stirring is carried out in a water bath at 70 ° C for 1 hour to obtain a mixed slurry; then the mixed slurry is put into a polytetrafluoroethylene tank Ball milling for 8 hours, the ball milling medium is aluminum nitride balls, after the ball milling, the slurry is sieved and defoamed to obtain the casting slurry; the casting slurry is passed through the castin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com