Chitin-based flame retardant, flame-retardant paper and preparation method of flame-retardant paper

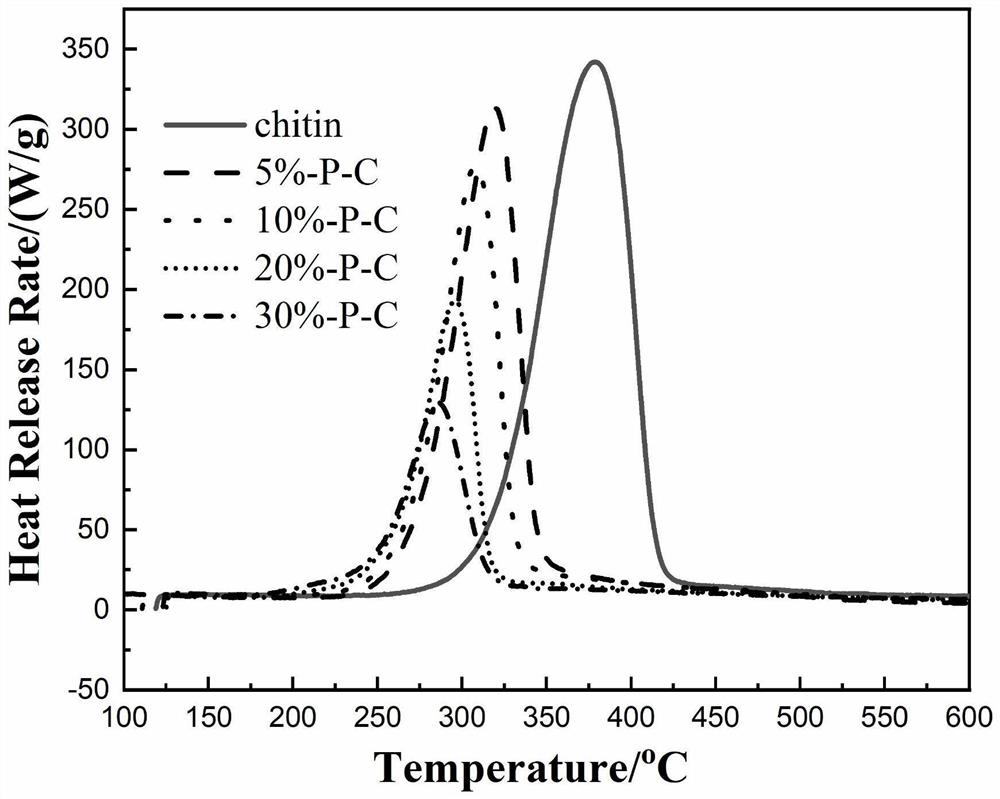

A technology of chitin and flame retardant, which is applied in the field of flame retardant paper, can solve the problems of cumbersome preparation method of flame retardant paper, and achieve the effects of easy popularization and application, good thermal stability and high carbon-forming property.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054]This embodiment provides a matrix-based damping agent, the preparation method of the chin-based resistance fuel is as follows:

[0055](1) Press the chorin and N, N-dimethylformamide to be added to the ball mill in mass ratio of 1:20 to prepare a chorin fiber; the ball mill is 20 h, and the rotational speed is 540 rpm;

[0056](2) The chipper fibers are added to a three-mouth flask in a 250 ml of pentoxide, and methanesulfonic acid is added.2After 16 h at 50 ° C, after the reaction was completed, washed with water, that is, a paced chromaticizing agent;

[0057]Wherein, the weight volume ratio of the chin fiber and the methanesulfonic acid is 1: 1 (g / ml); the mass ratio of the phosphorus oxide and the chin fiber is 4: 1.

[0058]This embodiment also provides a flame-retardant paper, and the preparation method of the flame-retardant paper is as follows: The chip-based damping agent obtained by the present embodiment is mixed with pulp, and the drying paper is obtained.

Embodiment 2

[0060]In this embodiment, a chip-based damping agent is provided, and the difference from Embodiment 1 is that the mass ratio of the pentoxide and the chlorin fibers in step (2) is 1: 1, the reaction time is 12h. .

[0061]This embodiment also provides a flame-retardant paper, and the preparation method of the flame-retardant paper is as follows: The chip-based damping agent obtained by the present embodiment is mixed with pulp, and the drying paper is obtained.

Embodiment 3

[0063]In this embodiment, a chrometric resistant agent is provided, and the difference from the first embodiment is that the mass ratio of the pentoxide and the chlorin fiber in step (2) is 3: 1, the reaction time is 12 h. .

[0064]This embodiment also provides a flame-retardant paper, and the preparation method of the flame-retardant paper is as follows: The chip-based damping agent obtained by the present embodiment is mixed with pulp, and the drying paper is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com