Coating agent, coated modified graphite negative electrode material, preparation method and application of coated modified graphite negative electrode material, and lithium ion battery

A coating agent, graphite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unfavorable industrial production, complex production process, and insufficient lithium insertion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

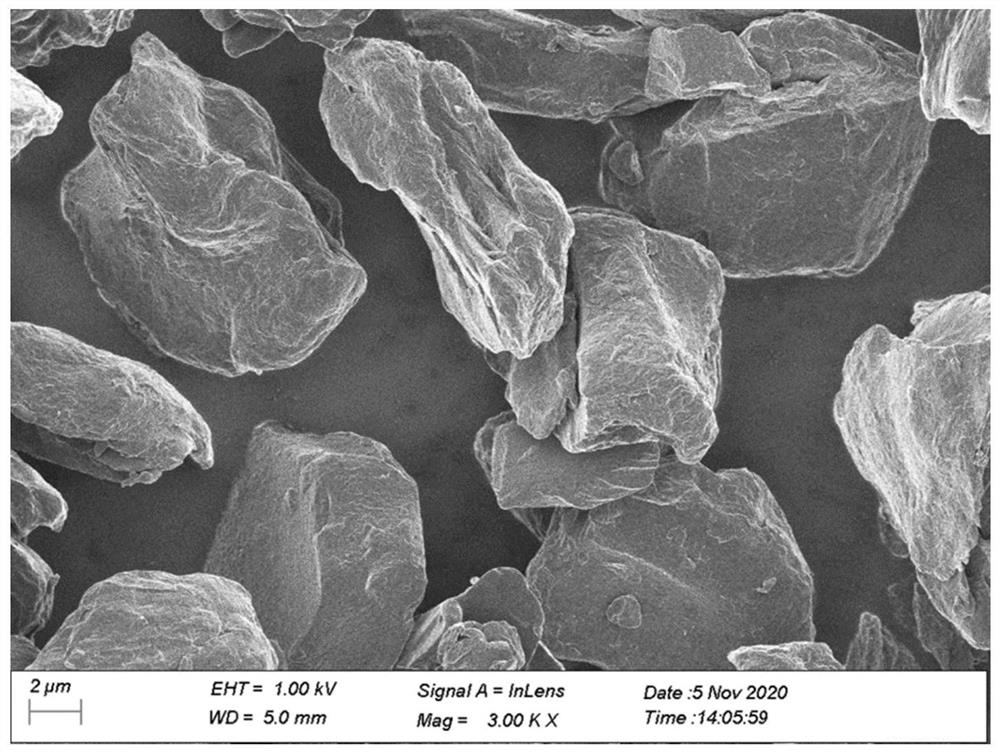

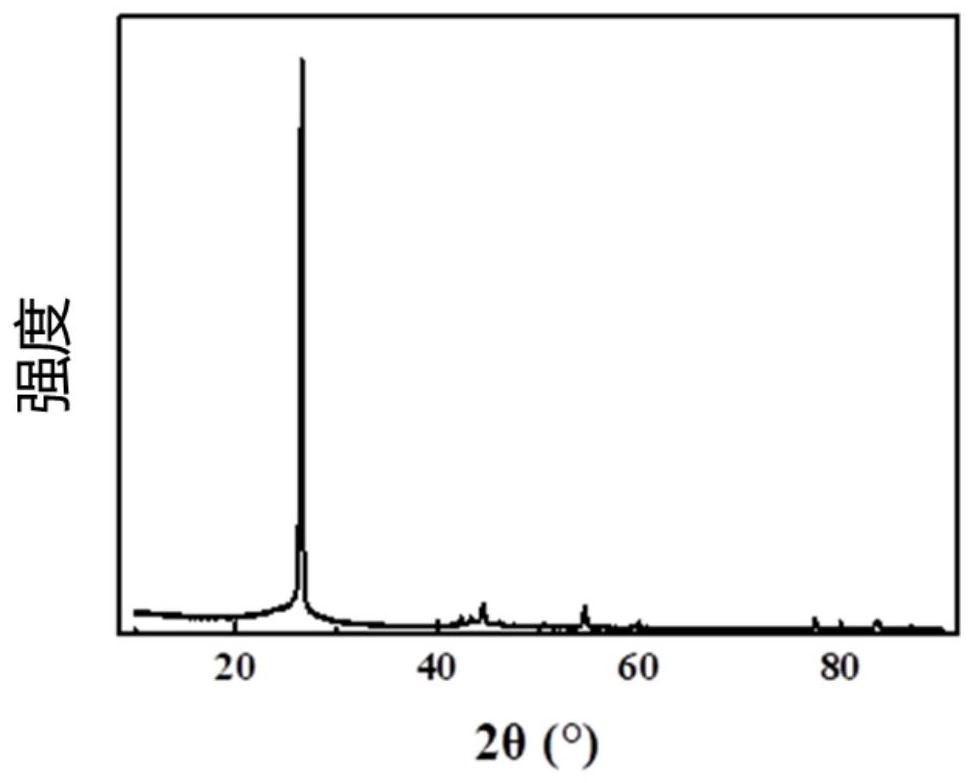

Image

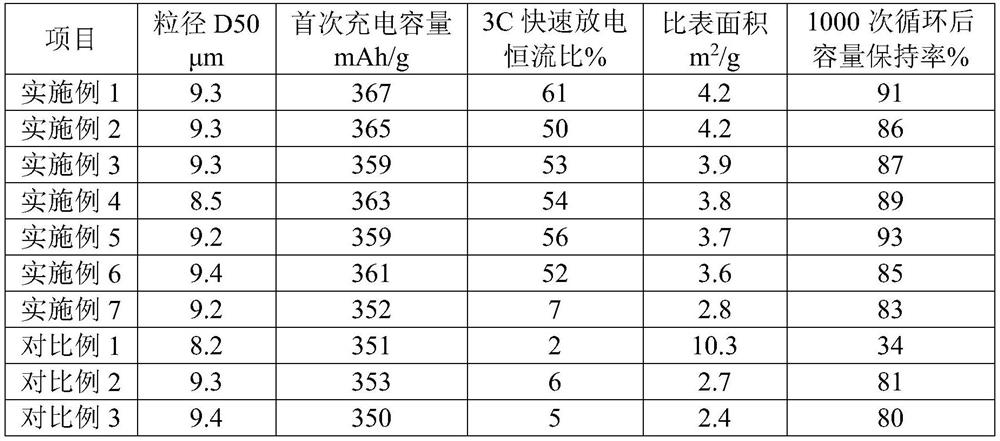

Examples

Embodiment 1

[0106]1 preparation of coated agent

[0107]The petroleum bitumen having a softening point is 250 ° C as a solute; toluene is used as a solvent; ammonium sulfate is used as a high temperature initiator, and its addition amount is 2 wt.%; DCP is added as a graft initiator, and the amount of 0.3 wt is added. .%; 0.1 wt.% Single-walled carbon nanotube nitromethylpyrrolidone as a conductive auxiliary agent, add amount of 0.1 wt.%; Polyvinylpyrrolidone K30 as a topical control aid, and add amount of negative electrode material. 0.4 wt.%; Acidic acid as a topographical control aid, add amount of 0.2 wt.% Of the negative electrode material. After the above materials were respectively weighed, stir mixed, the temperature was 120 ° C, the stirring time was 4 h, and after stirring was completed, it was used to use high pressure homogeneous machine homogeneous 3 times to obtain a coating agent having a coating value of 20%.

[0108]2 Preparation of coated modified graphite anode material

[0109]S1, wi...

Embodiment 2

[0113]In addition to the addition of 0.1 wt.% Of single-walled carbon nanotrophizine methylpyrrolidone during the preparation of the coating, other methods according to Example 1.

Embodiment 3

[0115]Except for the preparation of the coating agent, coal asphalt calculated according to the residual value: C9 petroleum resin = 3: 1 instead of petroleum asphalt, other methods according to Example 1 were carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com