Composite algal polysaccharide-based coating liquid and preparation method thereof

A technology of coating liquid and polysaccharide solution, which is applied in the fields of preserving meat/fish with a coating protection layer, protecting fruits/vegetables with a coating protection layer, food science, etc., and can solve the problem of natural biological preservatives, active packaging edible coatings Membrane research and application have not made major breakthroughs, the number of anaerobic bacteria in meat juice loss is high, and E. coli cannot be effectively controlled, etc., to achieve strong fresh-keeping and antibacterial effects, good stability and release characteristics, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Preparation of Sodium Alginate-Agar Gum-Ginger Essential Oil Composite Antibacterial Coating Solution

[0034] It mainly includes the following steps:

[0035] (1) Preparation of agar: select fresh, impurity-free asparagus, dry it, grind it into powder and pass through an 80-mesh sieve, take the powder and add absolute ethanol at a ratio of 1:10 (w / v) to soak overnight, remove the ethanol and dry it. After natural air-drying, extract by hot water reflux method (material-to-liquid ratio 1:60, water temperature 100°C, extraction time 120min, repeat extraction twice); the extract was frozen at -50°C for 12 hours, then redissolved at room temperature, centrifuged (4000rpm, 15 min) to remove the jelly in the lower layer; quickly freeze the jelly at -50°C for 24 hours, and then vacuum freeze-dry to obtain agar;

[0036] (2) Preparation of polysaccharide solution: Weigh a certain quality of raw materials according to sodium alginate: agar gel = 2:8 (m / m), add disti...

Embodiment 2

[0039] Example 2: The effect of sodium alginate-agar-ginger essential oil antibacterial coating solution on the physical and chemical properties of beef during storage and preservation

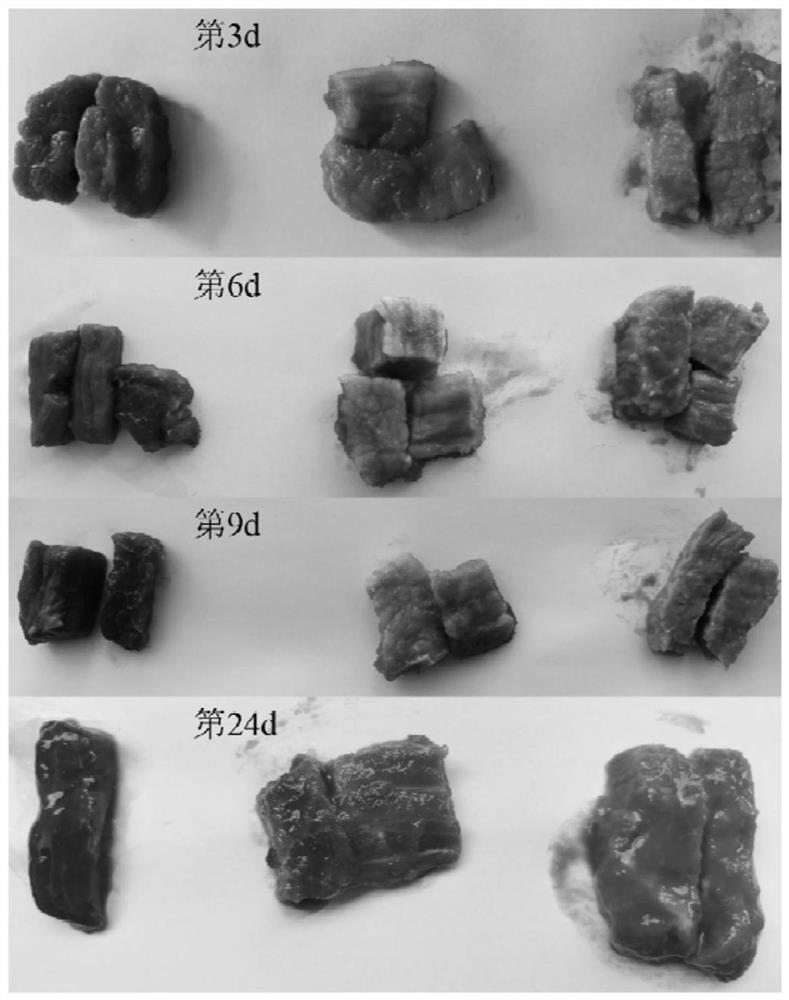

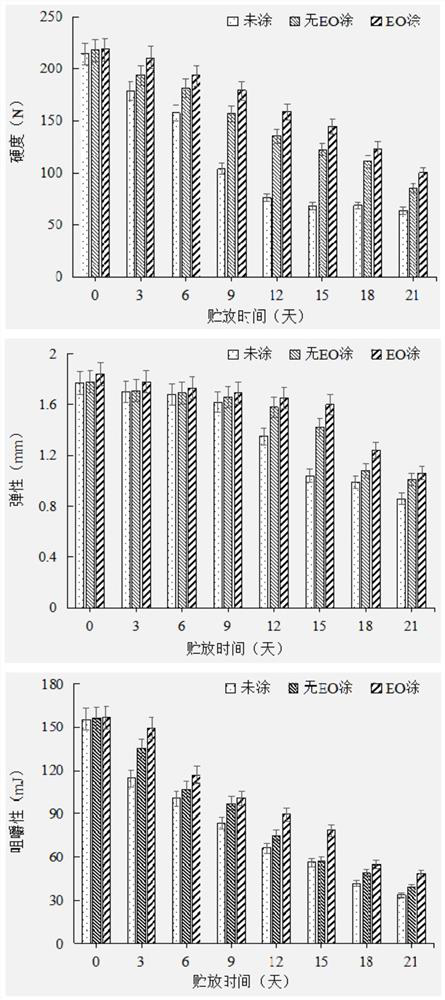

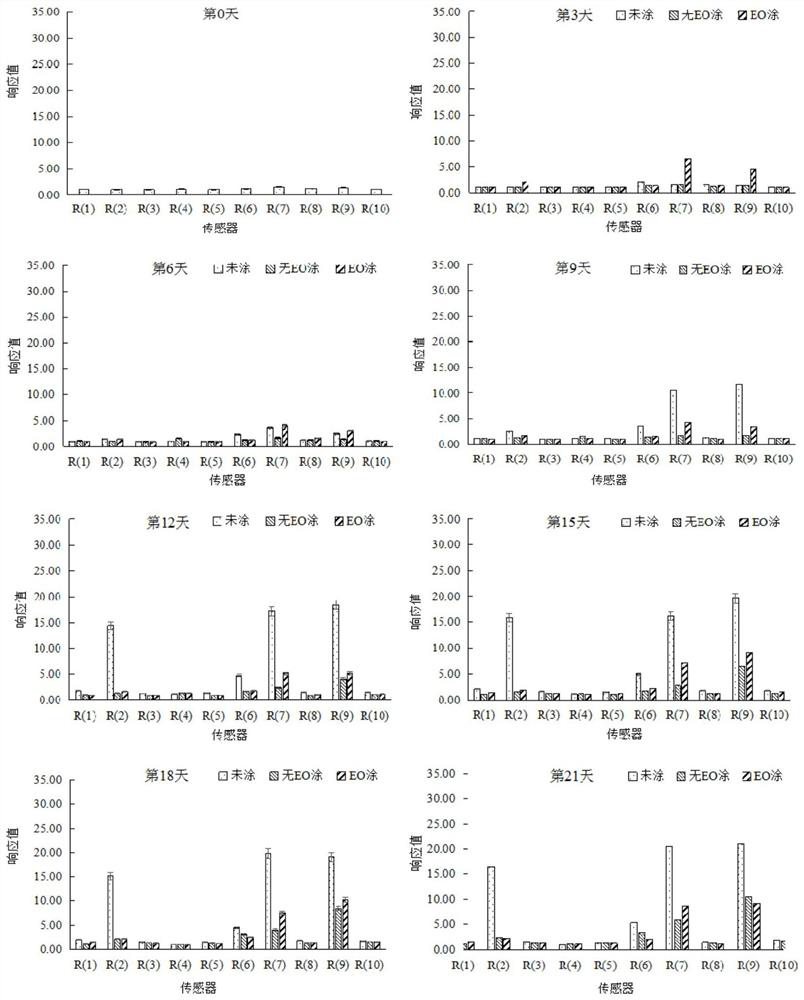

[0040] The sodium alginate-agar gum-ginger essential oil coating solution prepared in Example 1 is used for the coating preservation of fresh beef. Membrane treatment was control group 2. The beef samples of each treatment group were stored at 4°C, and samples were taken every 3 days for corresponding index detection. The results were as follows: figure 1 shown.

[0041] Meaty appearance without any coating solution:

[0042] Color: During the whole storage period, the color of the sample gradually deepened, from the bright red of the fresh meat sample to the dark brown at the end of storage (mainly produced by the oxidation of myoglobin in the meat sample). Odor: As the storage time goes by, the sample gradually produces an unpleasant smell, and finally produces a foul smell (mainly produc...

Embodiment 3

[0057] Example 3: Application of sodium alginate-agar gum-ginger essential oil compound antibacterial coating liquid in beef storage and preservation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com