Industrial ammonia-nitrogen organic wastewater treatment agent and preparation method thereof

A technology for organic wastewater treatment and ammonia nitrogen, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve difficult treatment, ammonia nitrogen has not been removed, and increase microbial treatment Load and impact load and other issues, to achieve the effect of enhanced adsorption performance, improved adsorption performance, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

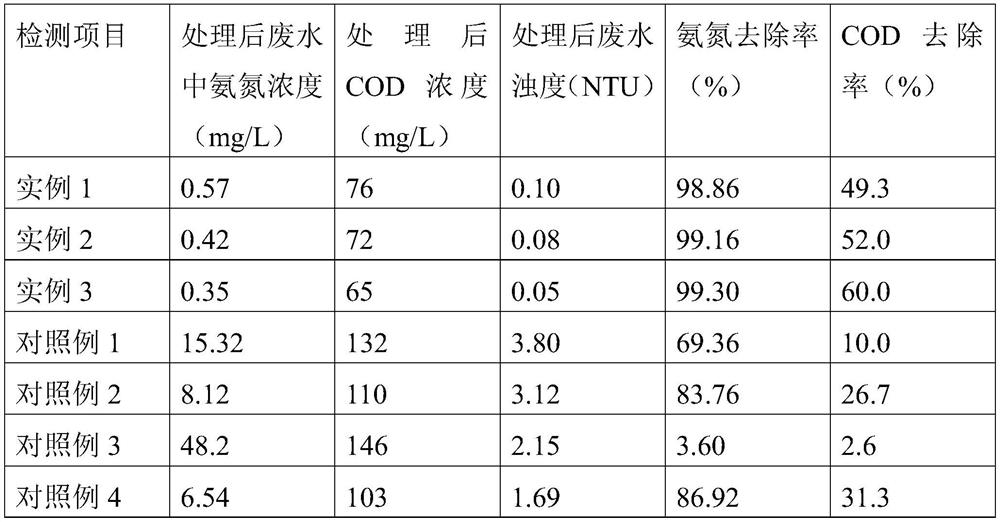

Examples

example 1

[0036] Mix magnesia and natural zeolite with a mass ratio of 1:4, put them into a sintering furnace, heat up to 400°C, keep warm and calcinate for 6 hours, after sintering, cool to room temperature with the furnace, and discharge to obtain modified zeolite particles;

[0037] In parts by weight, weigh 20 parts of sucrose, 4 parts of yeast powder, 1 part of urea, 10 parts of calcium chloride, 2 parts of magnesium sulfate, 5 parts of dipotassium hydrogen phosphate, 2 parts of potassium dihydrogen phosphate and 40 parts of deionized After the water is mixed, stir evenly to obtain the microbial enrichment solution;

[0038] Mix the modified zeolite particles and the microbial enrichment solution at a mass ratio of 1:10, put them into an ultrasonic oscillator, and ultrasonically oscillate and mix at a frequency of 25 kHz for 10 hours. Self-made zeolite carrier;

[0039] The above self-made zeolite carrier and deionized water are mixed according to the mass ratio of 2:1 as the ferm...

example 2

[0041] Mix magnesia and natural zeolite at a mass ratio of 1:4, put them into a sintering furnace, heat up to 430°C, keep warm and calcinate for 7 hours, after sintering, cool to room temperature with the furnace, and discharge to obtain modified zeolite particles;

[0042] In parts by weight, weigh 25 parts of sucrose, 5 parts of yeast powder, 1 part of urea, 13 parts of calcium chloride, 2 parts of magnesium sulfate, 5 parts of dipotassium hydrogen phosphate, 3 parts of potassium dihydrogen phosphate and 45 parts of deionized After the water is mixed, stir evenly to obtain the microbial enrichment solution;

[0043] Mix the modified zeolite particles and the microbial enrichment solution at a mass ratio of 1:10, put them into an ultrasonic oscillator, and ultrasonically oscillate and mix at a frequency of 30 kHz for 11 hours. Self-made zeolite carrier;

[0044] The above self-made zeolite carrier and deionized water are mixed according to the mass ratio of 2:1 as the fermen...

example 3

[0046] Mix magnesia and natural zeolite at a mass ratio of 1:4, put them into a sintering furnace, heat up to 450°C, keep the temperature and calcinate for 8 hours, after sintering, cool to room temperature with the furnace, and discharge to obtain modified zeolite particles;

[0047] In parts by weight, weigh 30 parts of sucrose, 6 parts of yeast powder, 2 parts of urea, 15 parts of calcium chloride, 3 parts of magnesium sulfate, 6 parts of dipotassium hydrogen phosphate, 3 parts of potassium dihydrogen phosphate and 50 parts of deionized After the water is mixed, stir evenly to obtain the microbial enrichment solution;

[0048] Mix the modified zeolite particles and the microbial enrichment solution at a mass ratio of 1:10, put them into an ultrasonic oscillator, and perform ultrasonic oscillation and mixing treatment at a frequency of 35 kHz for 12 hours. After the ultrasonic oscillation mixing treatment is completed, filter and separate to obtain a filter residue, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com