Preparation method and application of nano carbon dioxide capture agent

A carbon dioxide and scavenger technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of high energy consumption for desorption, high energy consumption for regeneration, and poor selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

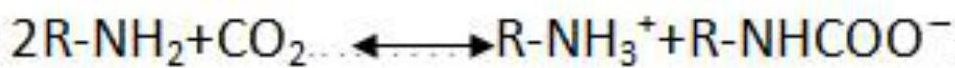

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

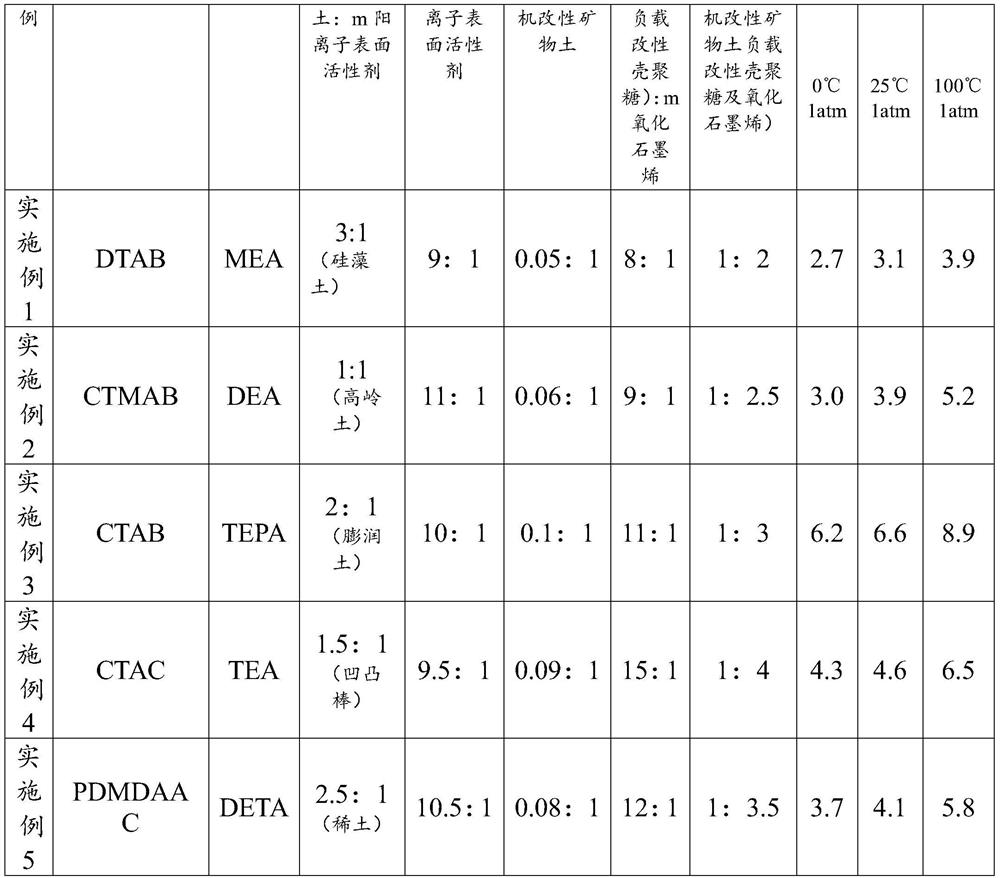

Embodiment 1

[0046] The preparation method of nano carbon dioxide capture agent specifically comprises the following steps:

[0047] 1. The first step: according to the ratio of m (diatomaceous earth): m (dodecyltrimethylammonium bromide (DTAB)) = 3:1, dissolve them in deionized water with a mass volume ratio of 11g / L, and add In a reaction kettle with a heating jacket, the rotation speed is 600r / min, heated and stirred at 80°C for 1h, and the pH is adjusted to 8 with ethanolamine (MEA) to obtain dodecyltrimethylammonium bromide (DTAB) modified organic diatomite ;

[0048] 2. The second step: Dissolve chitosan in acetic acid (concentration 5%) in proportion (mass volume ratio 100g / L), add it to the reaction kettle with heating jacket, rotate at 500r / min, heat and stir at 60°C completely Dissolve; according to the ratio m (chitosan): m (dodecyltrimethylammonium bromide (DTAB)) = 9: 1, rotate at 450r / min, heat and stir at 70°C for 1h to dissolve completely, add ethanolamine (MEA ) to compl...

Embodiment 2

[0053] The preparation method of nano carbon dioxide capture agent specifically comprises the following steps:

[0054] 1. The first step: according to the ratio of m (kaolin): m (octadecyltrimethylammonium bromide (CTMAB)) = 1:1, dissolve them in deionized water (mass volume ratio 14g / L), add In a reaction kettle with a heating jacket, the rotation speed is 500r / min, heated and stirred at 70°C for 2h, and the pH=8 is adjusted with diethanolamine (DEA) to obtain octadecyltrimethylammonium bromide (CTMAB) modified organic kaolin;

[0055] 2. The second step: Dissolve chitosan in acetic acid (concentration 5%) in proportion (mass volume ratio 100g / L), add it to the reaction kettle with heating jacket, rotate at 500r / min, heat and stir at 70°C completely Dissolve; according to the ratio of m (chitosan): m (octadecyltrimethylammonium bromide (CTMAB)) is 11:1, rotate at 500r / min, heat and stir at 60°C to dissolve completely, add diethanolamine (DEA) dropwise ) to completely dissol...

Embodiment 3

[0060]The preparation method of nano carbon dioxide capture agent specifically comprises the following steps:

[0061] 1. The first step: according to the ratio of m (bentonite): m (cetyltrimethylammonium bromide (CTAB)) is 2:1, dissolve in (12g / L) deionized water respectively, add the heating clamp In a reaction kettle with a cover, the rotation speed is 500r / min, heated and stirred at 70°C for 2h, and tetraethylenepentamine (TEPA) is used to adjust pH=8 to obtain cetyltrimethylammonium bromide (CTAB) modified organobentonite;

[0062] 2. The second step: Dissolve chitosan in acetic acid (concentration: 5%) in proportion (100g / L), add it into the reaction kettle with heating jacket, rotate at 500r / min, heat and stir at 60°C to dissolve completely; press The ratio of m (chitosan): m (cetyltrimethylammonium bromide (CTAB)) is 10:1, the rotation speed is 500r / min, heated and stirred at 60°C to dissolve completely, and cetyltrimethylammonium is added dropwise Ammonium bromide (C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com