Suspension polymerization process high-salt organic wastewater recycling treatment process

A suspension polymerization, organic wastewater technology, applied in special compound water treatment, flotation water/sewage treatment, water/sewage treatment, etc., can solve the problems of high investment and operation cost, harsh control of reaction conditions, poor biological tolerance, etc. Achieve the effect of reducing the cost of chemicals and solid waste disposal, avoiding the generation of a large amount of miscellaneous salt solid waste, and changing the structure of toxic organics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

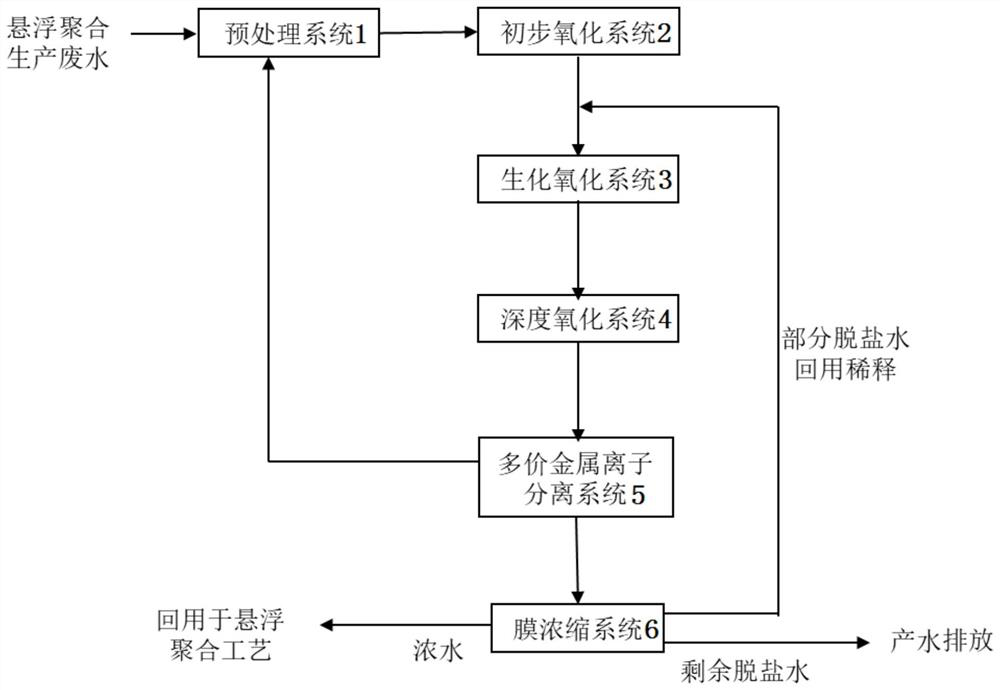

Method used

Image

Examples

Embodiment 1

[0046] Special acrylate wastewater is treated as the treatment object, the concentration of sodium chloride is 60 g / L, and the COD is 28000 mg / L. After pretreatment, the COD of the effluent water is reduced to 25000mg / L, and after the preliminary chemical oxidation, the COD is reduced to 18000mg / L. The concentration of sodium chloride is diluted to 20g / L with 2 times dilution water, and the COD can be reduced to 500mg after biochemical treatment. / L, deep oxidation of biochemical effluent can reduce COD to less than 200mg / L, and membrane concentration of deep oxidation product water can concentrate the salt content of the concentrated water side to more than 10%, and the COD of the concentrated water side is 500mg / L, which can be reused In the front-end suspension polymerization process.

[0047] principle:

[0048] 1. Adopt the mode of chemical oxidation coupled with biochemistry, use preliminary chemical oxidation to break the chain of oligomers in the suspended polymerizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com