Method for preparing hyperelastic silicon oxide nano ceramic aerogel based on graphene as template

A technology of graphene airgel and nano-ceramics, which is applied in ceramic products, applications, household appliances, etc., can solve the problem of affecting the thermal insulation performance of silica airgel, silica airgel is brittle and fragile, and is difficult to industrialize Application and other issues, to achieve excellent thermal properties and mechanical properties, improve economic and social benefits, and shorten the synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

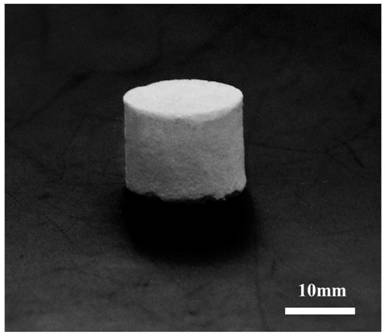

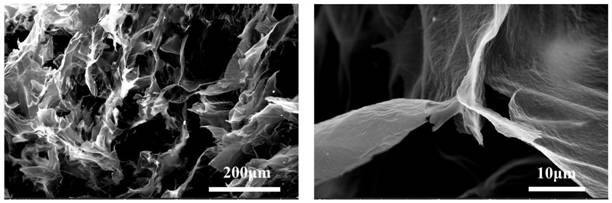

Image

Examples

Embodiment 1

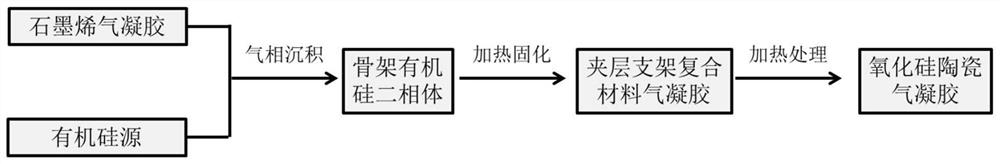

[0030]A method of preparing an ultra-elastic silica nanopharacemic gas gel based on graphene is, including the steps of:

[0031]Step 1: Preparation of 3D graphene gel template

[0032](1), the concentration is 1 mg / ml of large-piece oxahydrophene raw material, after ultrasonic treatment to good fluidity, add 5 ‰ ethylenediamine, and again ultrasound to good fluidity;

[0033](2), the treatment of oxide oxide raw materials is added to the mold preparative, and the molded mold is placed in the reactor, and the reaction kettle is placed in a vacuum drying tank, and the corresponding graphite is obtained after the water is hot. Allene gel;

[0034](3), the obtained graphene hydrogel is placed in a 20vol.% Ethanol solution of 24 to 48 h, and finally the hydrogel is freeze and remove the solution to obtain a regular porous gas gel, and annealed at 950 to 1000 ° C. 30min to get a three-dimensional graphene gel;

[0035]Step 2: Preparation of the silicone source

[0036](1), according to the volume ratio ...

Embodiment 2

[0047]A method of preparing an ultra-elastic silica nanopharacemic gas gel based on graphene is, including the steps of:

[0048]Step 1: Preparation of 3D graphene gel template

[0049](1), the concentration of 5 mg / ml of large-piece oxahydrophene raw material, after ultrasonic treatment to good fluidity, add 5 ‰ ethylenediamine, and ultrasound to good fluidity;

[0050](2), the treatment of oxide oxide raw materials is added to the mold preparative, and the molded mold is placed in the reactor, and the reaction kettle is placed in a vacuum drying tank, and the corresponding graphite is obtained after the water is hot. Allene gel;

[0051](3) The resulting graphene hydrogel is placed in a 20vol.%. The ethanol solution is soakeded 24 to 48 h, and finally the hydrogel is freeze and remove the solution to obtain a regular porous gas gel, and 950 ~ 1000 ° C is annealed for 30 min. To get a three-dimensional graphene gel;

[0052]Step 2: Preparation of the silicone source

[0053](1), according to volum...

Embodiment 3

[0064]A method of preparing an ultra-elastic silica nanopharacemic gas gel based on graphene is, including the steps of:

[0065]Step 1: Preparation of 3D graphene gel template

[0066](1), the concentration of a large-sheet oxide oxide raw material having a concentration of 10 mg / ml is obtained by ultrasonic treatment to a good fluidity, and 5 ‰ ethylenediamine is added, and it is again ultrasound to the fluidity;

[0067](2), the treatment of oxide oxide raw materials is added to the mold preparative, and the molded mold is placed in the reactor, and the reaction kettle is placed in a vacuum drying tank, and the corresponding graphite is obtained after the water is hot. Allene gel;

[0068](3) The obtained graphene hydrogel was submerged in a 20vol.% Ethanol solution of 24 to 48 h, and finally the hydrogel was freeze and dried to remove the solution to obtain a regular porous gas gel, and 950 to 1000 ° C for 30 min. Get a three-dimensional graphene gel;

[0069]Step 2: Preparation of the silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com