Zr4+ ion doped CA6-based refractory material and preparation method thereof

A refractory material and ion doping technology, applied in the field of inorganic non-metallic materials, can solve problems such as cracking, reduced material performance, and unrealized Zr4+ effective doping, and achieves no pollution to the environment, low porosity, atmosphere and synthesis temperature less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

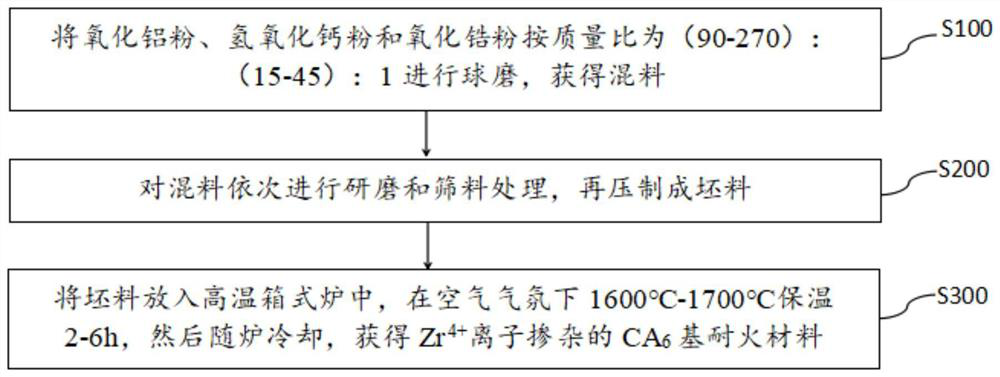

[0040] A kind of Zr provided by the invention 4+ ion-doped CA 6 The preparation method of base refractory material, see figure 1 , including the following steps:

[0041] S100, ball milling alumina powder, calcium hydroxide powder and zirconia powder in a mass ratio of (90-270):(15-45):1 to obtain a mixture;

[0042] S200, sequentially grinding and sieving the mixed material, and then pressing it into a billet;

[0043] S300. Put the billet into a high-temperature box furnace, keep it warm at 1600°C-1700°C for 2-6h in an air atmosphere, and then cool it with the furnace to obtain Zr 4+ ion-doped CA 6 base refractory material.

[0044] a Zr 4+ ion-doped CA 6 based refractories, including through Zr as described above 4+ ion-doped CA 6 CA based refractory preparation method 6 base refractory material.

[0045] A kind of Zr provided by the invention 4+ ion-doped CA 6 Material and its preparation method, by introducing Zr 4+ to improve CA 6 material properties can b...

Embodiment 1

[0058] a Zr 4+ ion-doped CA 6 The preparation method of base refractory material comprises:

[0059] (1) Raw material treatment: Alumina powder with an average particle size of 2 μm, calcium hydroxide powder with an average particle size of 2 μm, and zirconia powder with an average particle size of 100 nm were respectively incubated at 400° C. for 6 hours to remove free water and bound water in the raw materials. Wherein, the alumina powder is α-alumina powder.

[0060] (2) Ball milling and mixing: mix the treated alumina powder, calcium hydroxide powder and zirconia powder in a mass ratio of 270:45:1 and put them into a grinding tank, and use absolute ethanol as a medium to adopt a wet ball milling method. Among them, the mass ratio of balls: mixed powder: absolute ethanol is 5:2:1; the ball milling speed is controlled at 250rpm / min, and the ball milling is carried out for 12 hours to make the raw materials evenly mixed, and then the mixed slurry is quickly dried to avoid s...

Embodiment 2

[0064] a Zr 4+ ion-doped CA 6 The preparation method of base refractory material comprises:

[0065] (1) Raw material treatment: Alumina powder with an average particle size of 4 μm, calcium hydroxide powder with an average particle size of 6 μm, and zirconia powder with an average particle size of 200 nm were respectively incubated at 500° C. for 5 hours to remove free water and bound water in the raw materials.

[0066] (2) Ball milling and mixing: mix the treated alumina powder, calcium hydroxide powder and zirconia powder in a mass ratio of 180:30:1 and put them into a grinding tank, and use absolute ethanol as a medium to adopt a wet ball milling method. Among them, the mass ratio of balls: mixed powder: anhydrous ethanol is 6:1:2; the ball milling speed is controlled at 200rpm / min, and the ball milling is carried out for 24 hours to make the raw materials evenly mixed, and then the mixed slurry is quickly dried to avoid stratification.

[0067] (3) Billet preparation: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com