Preparation method of lactic acid bacteria fermentation lysate and cracking device

The technology of a lactic acid bacteria fermentation and cracking device is applied in the lactic acid bacteria gas expansion cracking method to prepare a lactic acid bacteria fermentation lysate and a cracking device. The effect of high inhibition rate and high cracking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

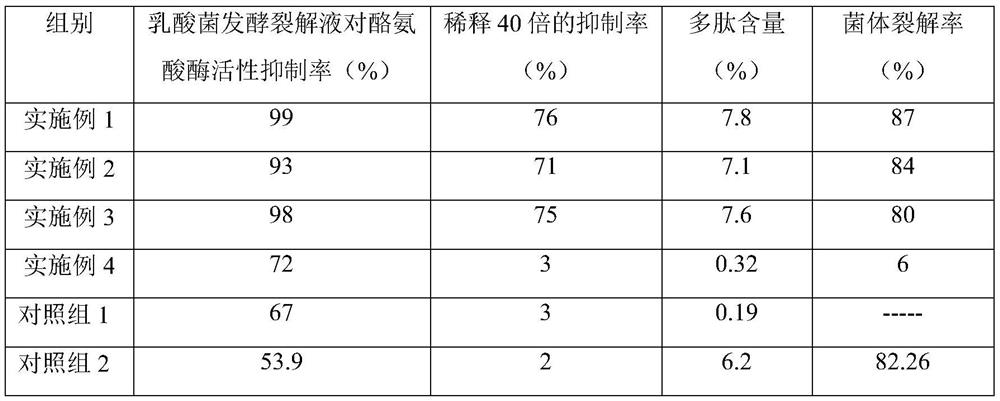

Examples

Embodiment 1

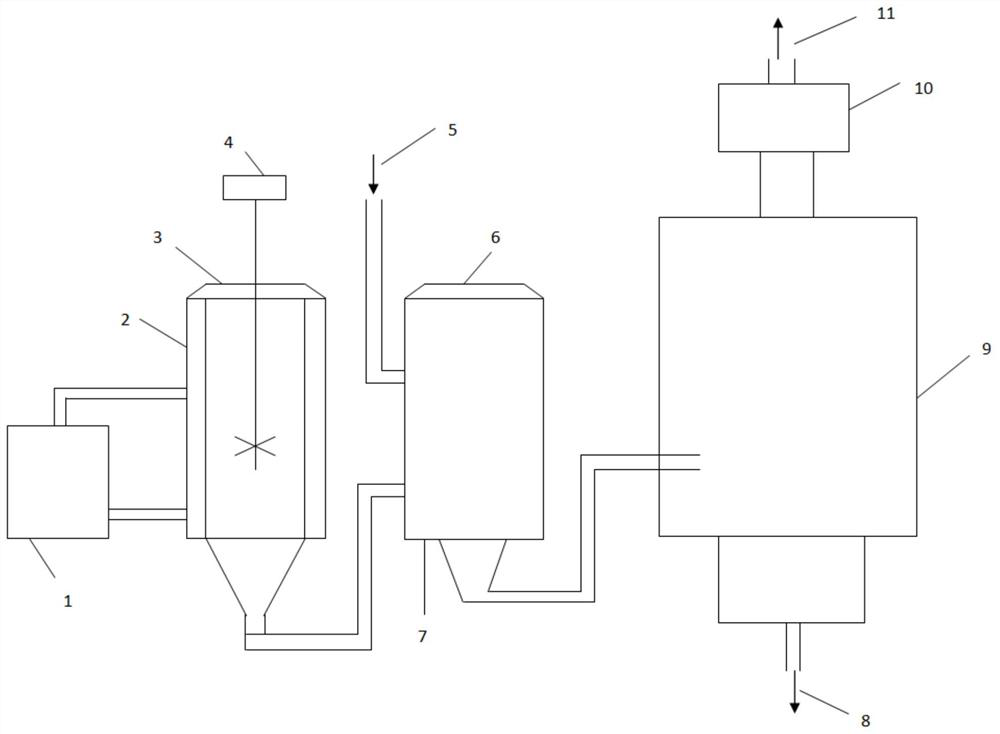

[0020] Cultivate lactic acid bacteria: xylooligosaccharide 3kg, pearl powder 5kg, glucose 6kg, lactic acid bacteria (dry weight) 0.5kg, milk powder 6kg, water 79.5kg. Such as figure 1 As shown, open the cover 3, put the above-mentioned fermentation raw materials into the fermenter 2 that can be put into 200 liters of water, stir evenly by the mixer 4, keep the temperature at 25 degrees Celsius by the thermostat 1, keep warm for 10h, and obtain 98.7kg of fermented product. The fermented product enters in the 200-liter high-pressure tank 7 through the discharge pipe, and the high-pressure tank 7 can be sealed by the cover 6, and a temperature regulating device and a pressurizing device are also provided (the temperature regulating device and the pressurizing device are both prior art), The pipeline 5 that can pass into gas is arranged on the top of the high-pressure tank 7, and the pipeline 5 can pass into the gas; there is a discharge pipe at the bottom of the high-pressure tan...

Embodiment 2

[0023] Cultivate lactic acid bacteria: xylooligosaccharide 3kg, pearl powder 5kg, glucose 6kg, lactic acid bacteria (dry weight) 0.5kg, milk powder 6kg, water 79.5kg. Such as figure 1 As shown, open the cover 3, put the above-mentioned fermentation raw materials into the fermenter 2 that can be put into 200 liters of water, stir evenly by the mixer 4, keep the temperature at 25 degrees Celsius by the thermostat 1, keep warm for 10h, and obtain 98.7kg of fermented product. The fermented product enters in the 200-liter high-pressure tank 7 through the discharge pipe, and the high-pressure tank 7 can be sealed by the cover 6, and a temperature regulating device and a pressurizing device are also provided (the temperature regulating device and the pressurizing device are both prior art), The pipeline 5 that can pass into gas is arranged on the top of the high-pressure tank 7, and the pipeline 5 can pass into the gas; there is a discharge pipe at the bottom of the high-pressure tan...

Embodiment 3

[0026] Cultivate lactic acid bacteria: xylooligosaccharide 3kg, pearl powder 5kg, glucose 6kg, lactic acid bacteria (dry weight) 0.5kg, milk powder 6kg, water 79.5kg. Such as figure 1 As shown, open the cover 3, put the above-mentioned fermentation raw materials into the fermenter 2 that can be put into 200 liters of water, stir evenly by the mixer 4, keep the temperature at 25 degrees Celsius by the thermostat 1, keep warm for 10h, and obtain 98.7kg of fermented product. The fermented product enters in the 200-liter high-pressure tank 7 through the discharge pipe, and the high-pressure tank 7 can be sealed by the cover 6, and a temperature regulating device and a pressurizing device are also provided (the temperature regulating device and the pressurizing device are both prior art), The pipeline 5 that can pass into gas is arranged on the top of the high-pressure tank 7, and the pipeline 5 can pass into the gas; there is a discharge pipe at the bottom of the high-pressure tan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap