Product comprising protective coating and method of making product

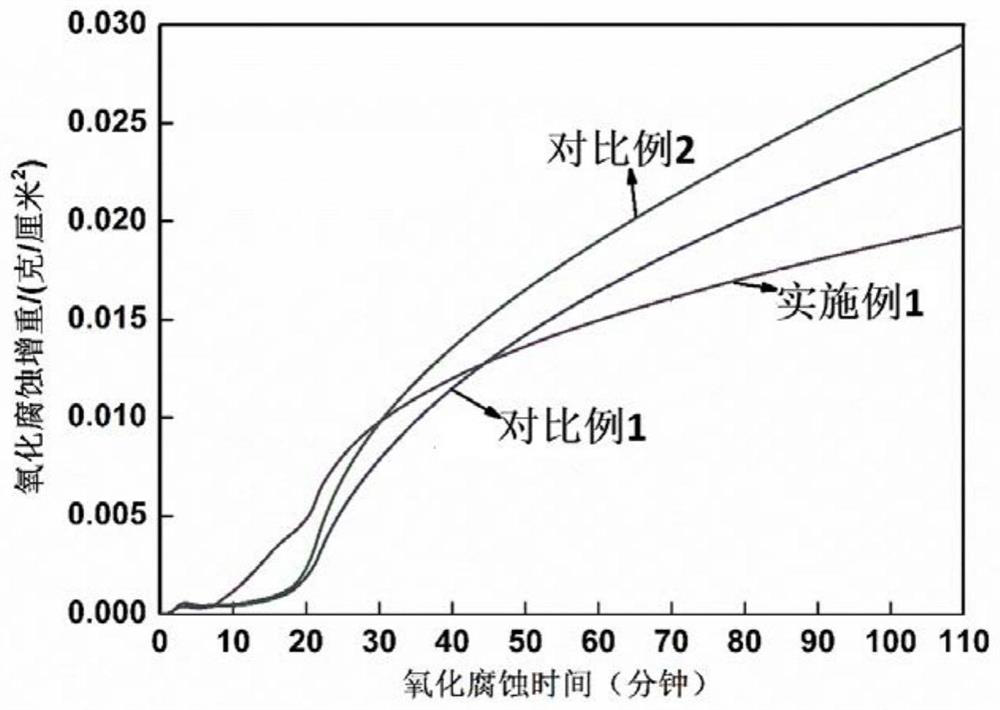

A protective coating and product technology, applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problem of providing sufficient protection for zirconium alloy cladding materials, fast corrosion kinetics, and corrosion protection life Short and other problems, to achieve the effect of improving the fault tolerance of accidents and excellent resistance to water vapor corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of the above-mentioned product comprising a protective coating, the preparation method comprising the following steps:

[0033] S1, providing the matrix;

[0034] S2, using chromium as a target, depositing a chromium layer on the surface of the substrate by DC magnetron sputtering to obtain a product including a protective coating, wherein the cavity pressure of the DC magnetron sputtering method is 0.2Pa -0.3Pa, preferably 0.25Pa-0.3Pa; the power density of the target is 5w / cm 2 -7.2w / cm 2 , preferably 6.0w / cm 2 -7.0w / cm 2 ; The time is 5h-12h, preferably 8h-12h.

[0035] In step S1, the substrate may be a zirconium alloy substrate.

[0036] In one embodiment, the substrate may be pretreated, and the pretreatment process includes: ultrasonically cleaning the substrate with an organic solvent. Preferably, the steps include using different organic solvents to sequentially perform ultrasonic cleaning on the su...

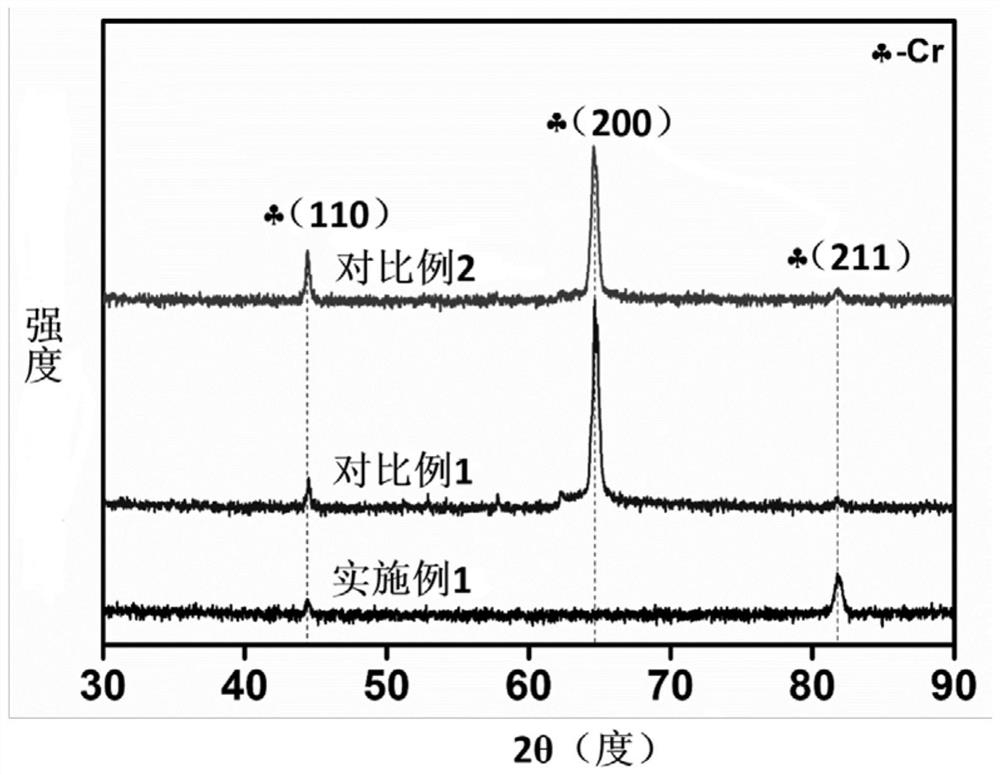

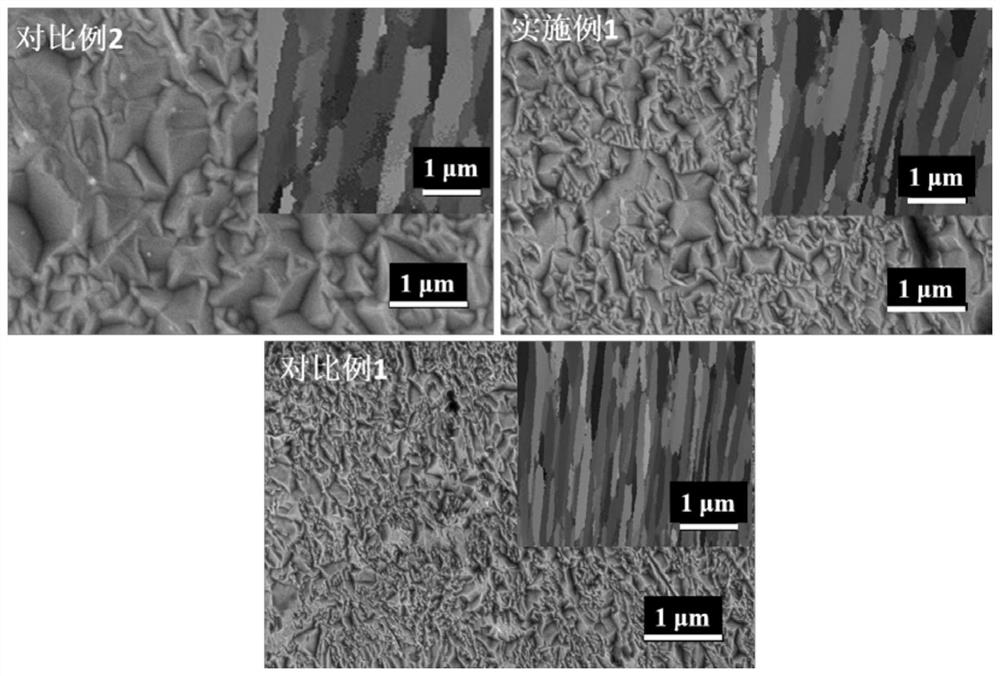

Embodiment 1

[0045] (1) The zirconium alloy substrate is ultrasonically cleaned with acetone and ethanol respectively, and then the zirconium alloy substrate is fixed on the sample holder in the vacuum coating chamber.

[0046] (2) Heat the chamber to 200°C, and vacuum the chamber to 3.0×10 -3 Pa. Then the sample holder is rotated to the front of the chromium target to maintain rotation, and argon gas with a flow rate of 40 sccm is introduced into the vacuum cavity. The current of the linear anode ion source was set to 0.2A, the negative bias voltage of the substrate was set to -150V, and the substrate was etched for 20 minutes with ionized argon ions.

[0047] (3) Admit argon gas into the cavity, and maintain the pressure at 0.3Pa. Keep the distance between the zirconium alloy substrate and the target surface at 12cm, and set the power density of the chromium target to 6.6w / cm 2 , the bias voltage of the zirconium alloy substrate was set to -125V, and a chromium layer was deposited on ...

Embodiment 2

[0049] (1) The zirconium alloy substrate is ultrasonically cleaned with acetone and ethanol respectively, and then the zirconium alloy substrate is fixed on the sample holder in the vacuum coating chamber.

[0050] (2) Heat the chamber to 200°C, and vacuum the chamber to 3.0×10 -3 Pa. Then the sample holder is rotated to the front of the chromium target to maintain rotation, and argon gas with a flow rate of 40 sccm is introduced into the vacuum cavity. The current of the linear anode ion source was set to 0.2A, the negative bias voltage of the substrate was set to -150V, and the substrate was etched for 20 minutes with ionized argon ions.

[0051] (3) Admit argon gas into the cavity, and maintain the pressure at 0.25Pa. Keep the distance between the zirconium alloy substrate and the target surface at 12cm, and set the power density of the chromium target to 7.2w / cm 2 , the bias voltage of the zirconium alloy substrate was set to -125V, and the chromium layer was deposited ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com