Ti2AlC corrosion resisting coating preparing method

A corrosion-resistant coating and suspension technology, used in coatings, electrolytic coatings, electrophoretic plating, etc., can solve problems such as difficulty in controlling the thickness and density of coatings, oxidative decomposition of coating materials, and thermal damage to substrate materials. High efficiency and speed to achieve equipment requirements, promote interface sintering, control structure and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

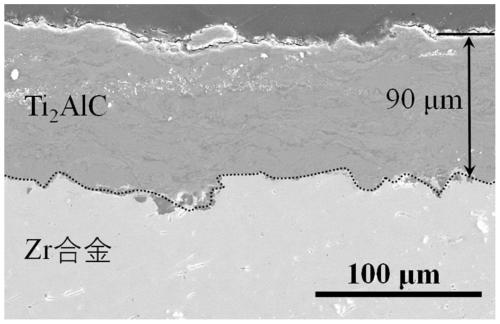

[0032] A kind of Ti 2 The preparation method of AlC corrosion-resistant coating comprises:

[0033] (1) Take titanium aluminum carbon (Ti 2 AlC) powder (100nm-2μm) is dispersed in isopropanol, prepared into a suspension with a concentration of 20-80g / L, placed in an ultrasonic generator and vibrated for 30-100min, then taken out and placed on a magnetic stirrer for stirring 6 ~ 48h, configured into a uniform suspension A;

[0034] (2) Then add elemental tellurium (Te) to the above suspension A, control the concentration of elemental tellurium to 0.1-1.0g / L, then put the suspension A into the ultrasonic generator and vibrate for 30-100min, take it out and put it Stir on a magnetic stirrer for 6-48 hours to obtain suspension B;

[0035](3) Pour the suspension B into the polytetrafluoroethylene container, then clamp the ZIRLO alloy sample (15mm×20mm) after sandblasting on the cathode clamp of the polytetrafluoroethylene container cover, and use the graphite electrode as the an...

Embodiment 1

[0047] A kind of Ti 2 The preparation method of AlC corrosion-resistant coating comprises:

[0048] (1) Take titanium aluminum carbon (Ti 2 AlC) powder (200nm) was dispersed in isopropanol, prepared into a suspension with a concentration of 30 g / L, placed in an ultrasonic generator and vibrated for 40 minutes, then placed on a magnetic stirrer and stirred for 12 hours after taking it out, and configured into a uniform Suspension A;

[0049] (2) Then add elemental tellurium (Te) to the above-mentioned suspension A, control the concentration of elemental tellurium to be 0.2g / L, then put the suspension A into the ultrasonic generator and vibrate for 40min, take it out and put it on a magnetic stirrer Stir for 12h to obtain suspension B;

[0050] (3) Pour the suspension B into the polytetrafluoroethylene container, then clamp the ZIRLO alloy sample (15mm×20mm) after sandblasting on the cathode clamp of the polytetrafluoroethylene container cover, and use the graphite electrode ...

Embodiment 2

[0053] A kind of Ti 2 The preparation method of AlC corrosion-resistant coating comprises:

[0054] (1) Take titanium aluminum carbon (Ti 2 AlC) powder (500nm) is dispersed in isopropanol, prepared into a suspension with a concentration of 50 g / L, placed in an ultrasonic generator and vibrated for 50 minutes, then placed on a magnetic stirrer and stirred for 18 hours after being taken out, and configured into a uniform Suspension A;

[0055] (2) Then add elemental tellurium (Te) to the above-mentioned suspension A, control the concentration of elemental tellurium to be 0.3g / L, then put the suspension A into the ultrasonic generator and vibrate for 50min, take it out and place it on a magnetic stirrer Stir for 18h to obtain suspension B;

[0056] (3) Pour the suspension B into the polytetrafluoroethylene container, then clamp the ZIRLO alloy sample (15mm×20mm) after sandblasting on the cathode clamp of the polytetrafluoroethylene container cover, and use the graphite electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com